Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

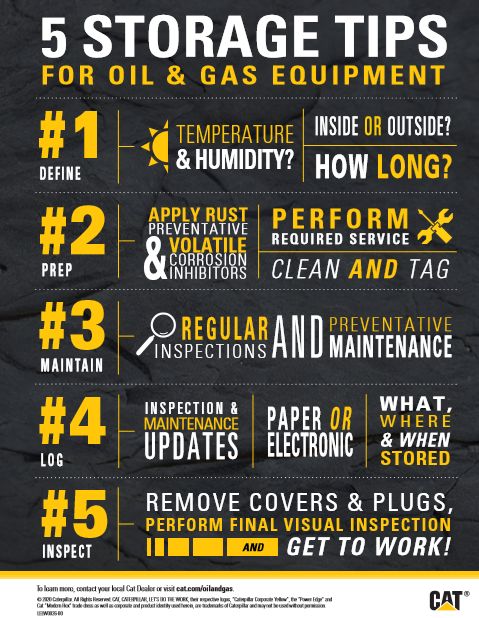

5 Storage Tips For Oil & Gas Equipment

PRESERVE EQUIPMENT TO KEEP YOUR INVESTMENT RUNNING STRONG

Planning to put some of your Cat® oil and gas equipment into storage for an extended period of time? Make sure your engines, electric motors, transmissions or pumps are ready to go again when market conditions change or new projects get underway. There’s no one-size-fits-all method for storing and preserving equipment, but following these guidelines can reduce your risk of corrosion and component damage and improve start-up performance.

1. Define your storage conditions: Are you storing equipment inside or outside? What’s the temperature and humidity? Will you be storing the product for a month or a year? More extreme conditions and a longer storage duration require additional preparation and maintenance. (In areas of high humidity, for example, a lack of lubrication can lead to corrosion and cause excessive wear on start-up.) Your Cat dealer can help you determine the most appropriate procedures for your specific situation.

2. Prep equipment for storage: Clean and tag every item, apply rust preventative and volatile corrosion inhibitors as directed and service the fluids and filters, then add covers or plugs. For engines, service the aftertreatment and cooling/fuel systems, loosen bolts and disconnect and store batteries. For electric motors, add desiccant to the terminal box, perform baseline electrical tests, apply a shafter locking device and energize space heaters.

3. Maintain equipment during storage: Don’t just store it and forget it — regular visual inspections and ongoing preventive maintenance are critical. Test engine batteries and pre-lube and rotate engine, electric motor and pump drive lines on a regular schedule. Reapply rust preventative and volatile corrosion inhibitors as directed on engines and pumps. Maintain or replace terminal box desiccant and monitor space heater operation for electric motors.

4. Keep a storage logbook: It can be paper or electronic, but maintain a detailed record of what equipment is stored, where it’s stored and when it went into storage — along with updates on all inspections and preventive maintenance performed.

5. Inspect stored equipment before operation: When you’re ready to bring an engine, electric motor, transmission or pump out of storage and back into operation, remove any covers or plugs and perform a final visual inspection to ensure it’s ready to go to work.

Proper storage is key to preserving your equipment investment, and your local Cat dealer is on hand to help with the parts, fluids, tools and detailed procedures you need to store, maintain and keep your engines, motors, transmissions and pumps running strong.