Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

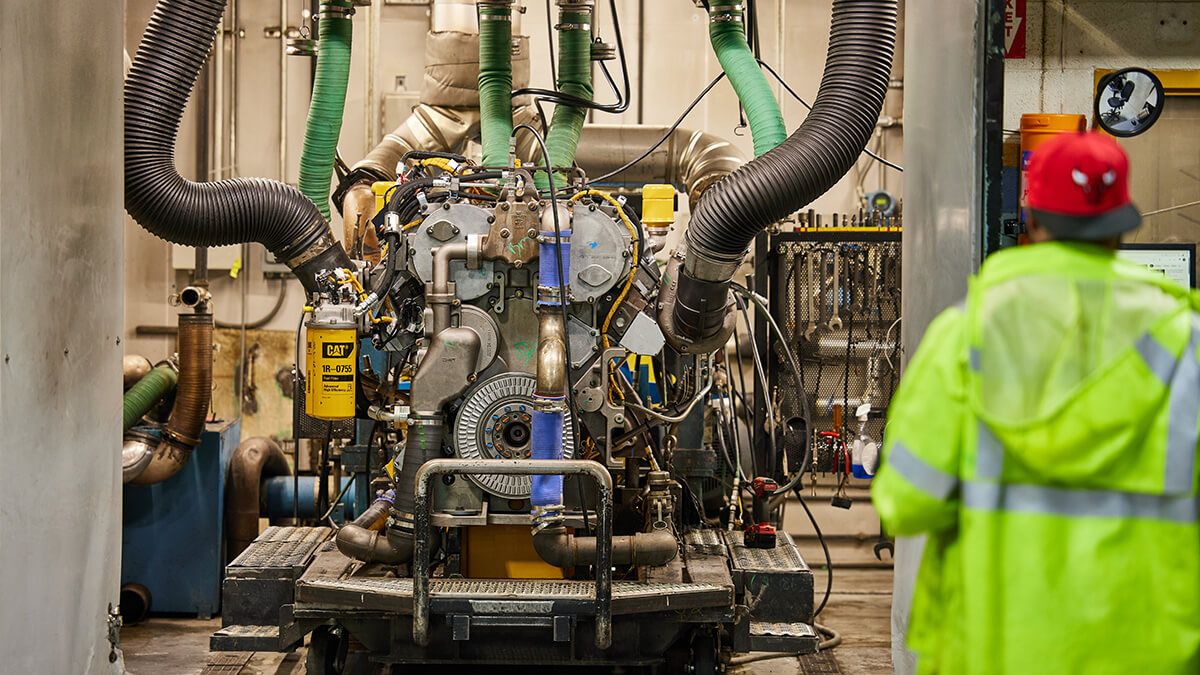

Engine Remanufacturing: Assembly and Final Testing

Here it all comes together: block prep, oil plugs, precision machined cranks and cams, then subassemblies with new wear components and genuine Caterpillar parts. And the rigorous final testing makes sure Cat® Reman engines perform like new.

Estimated read time: 3 minutes

Your engine has been fully disassembled and rigorously inspected. All its piece parts have been sorted out to the team that brings them back to Caterpillar performance specifications. And now, an assembly team collects the salvaged parts from your engine and from the engines of many others. They meticulously assemble the parts to create an engine that performs like new.

Technicians complete a number of final tests to make sure this engine is up to Caterpillar standards. Once approved, this Cat® Reman engine goes to the shelf at another Cat dealer, where an equipment owner will purchase it and benefit from your decision to return your old engine instead of scrapping it.

But the cycle doesn’t stop there. When your Cat Reman engine reaches the end of its second or third life, you can return the core to your Cat dealer and start the process all over again.

Step Six: Assembly

Assembly is just what it sounds like: putting all the parts together. “When a part gets to assembly it's added to an engine,” says Cat Reman Section Manager 4 Renea Miller.

Meanwhile, Manufacturing Engineer Joshua Brooks emphasizes how paramount quality control is. “Once it comes to assembly, my focus is to make sure that we are torquing our engines to spec, that we don't have any loose bolts … and that we have a quality product going out the door.”

First up for Engine Technician Jennifer Sparks is block preparation, where plugs are installed in oil galleys. After that, she and her team address the cranks, cam bearings and housings. “We install the front and rear housings and cams. That's when the subassemblies start — anything from turbos to oil filter bases, manifolds and heads. Wear components such as bearings, gaskets and seals are required to be 100% new genuine Cat parts, and those are added to the assembly as well," she says.

Subassembly is a big part of what Shannon Davis, who works on the Cat 3100 engine line, does. In her role, she assembles smaller piece parts into larger, more recognizable components.

Step Seven: Testing

And what’s the point of a remanufactured and assembled engine if it doesn’t work properly? Every Cat Reman engine undergoes functional performance tests to ensure like new quality and performance. “At the end of the line, we have a test cell where we run the engine to make sure it meets a new Cat engine’s performance specifications,” Brooks says.

Once it passes testing, the remanufactured engine is shipped to where it’s needed next.

Brooks describes remanufacturing as a constant process. “The core comes in, and we build the Cat Reman product back like new. It goes out to the customer and then toward the end of life, the core comes back in. It's a continuous cycle.”

And ultimately, this work is always done with the customer top of mind. As Davis says, “Everybody on the line is thinking about the customer. We want to build the engine the correct way, so they'll always come back.”

Check out the range and variety of available Cat Reman parts.