Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Hybrid Technologies Deliver Efficiencies

That Add Up

Solutions That Offer Fuel Flexibility and Autonomous Control are the Latest Tools to Help Reduce Costs

Parts & Services

-

Cat® Engine Lifecycle

Learn More -

Customer Value Agreements for Oil & Gas

Learn More -

Digital Services for Oil & Gas

Learn More -

Gas Compression Training

Learn More -

Finance and Warranty for Oil & Gas

Learn More -

Parts and Repair Options for Oil & Gas

Learn More -

Cat® Reman Solutions for Oil & Gas

Learn More

Sustainability

About

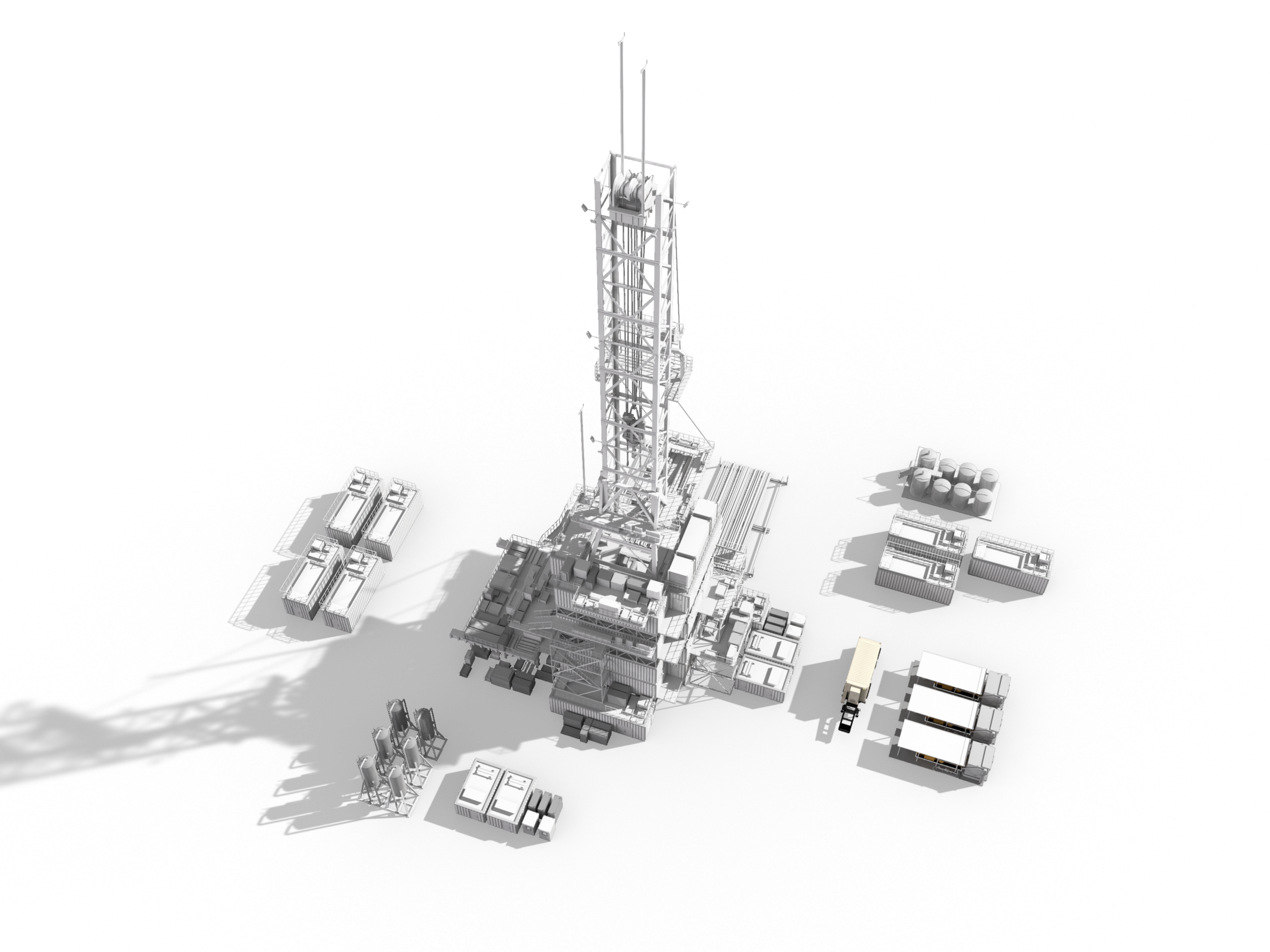

As fuel is always one of the greatest expenses in the oilfield, technological advances that drive greater efficiencies are top of mind for E&Ps and drilling operators. Newly available electrification and optimization technologies lower fuel consumption and related greenhouse gas emissions while maintaining on-site reliability and durability.

The Cat® Hybrid Energy Storage Solution employs a suite of technologies that stores excess power from the jobsite and then discharges that power as needed. When combined with a gas genset, this on-call ability enables a faster transient response than with diesel-only rigs. It easily configures into current rig setups, giving operators and drillers more flexibility when selecting fuel types. Additionally, it affords the ability to automatically add or remove engines to match demand. This promotes capital efficiency, reliability and greater safety while lowering emissions and costs.

With the Cat Smart Engine Management System (EMS), greater operational benefits are unlocked. This powerful technology aligns performance with programmed targets and helps reduce maintenance costs by lowering the number of runtime hours engines accumulate. With Smart EMS, drillers can reduce engine runtime up to 25%, cut fuel consumption up to 10% and improve diesel displacement up to 15% (compared to a diesel rig) without sacrificing power, performance or productivity.*

The Cat EMCP 4.4 digital controls technology underpins Smart EMS to provide enhanced genset paralleling and remote communications capabilities. EMCP 4.4 technology also supplies a robust human-machine interface (HMI) that gives drillers easy, touchscreen access to see rig demand and engine load at a glance for trusted remote oversight.

Cat natural-gas powered gensets are another component of this hybrid solution. Specifically engineered to run on wellsite gas, the gensets ensure an abundant supply of low-cost fuel. Customers can select the individual components that support their unique goals and project specifications for optimal benefits. This flexibility enables drillers to benefit from a complete, customized factory solution that provides proven reliability and durability.

These wellsite optimization technologies work together to give drillers and operators more insight and flexibility than in years past. With cost and competitive pressures, such solutions deliver powerful advantages in the field through carving out greater efficiencies to lower operating costs—and emissions.

Learn more about the Cat Hybrid Energy Storage Solution by visiting www.cat.com/hybridess.

*Results based on field data. Actual performance may vary.

Related Content

-

Hybrid Energy Storage Solution

The Cat® Hybrid Energy Storage Solution is your answer for energy efficiency—saving you time and money while offering better fuel efficiency, consistent on-site performance and more.

Learn More -

- Application

- Transient Assist

- Transient Assist

- Module Type

- Heavy Duty mobile Grid Stabilization

- Heavy Duty mobile Grid Stabilization

- Rated Power

- 1000-1260 kW

- 1000-1260 kW

Power Grid Stabilization (PGS) Heavy Duty (HD)

The Cat® PGS Module is a scalable, rapidly deployable energy storage system with a heavy-duty battery structure. The PGS integrates with solar and other renewable sources to provide short duration power when the renewable source is not available or virtual spinning reserve to optimize generator sets efficiency. This system provides transient assist and grid stabilization to the installation.

Learn More -

Cat Smart EMS

What if you could reduce runtime on your drilling rig engines up to 25 percent, cut fuel consumption up to 10 percent and increase gas consumption as well — without sacrificing power and productivity? With Smart EMS, you can.

Learn More