Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Understanding the Differences Between Lean-Burn and Rich-Burn Engines

Essential Considerations to Determine Which Type of Engine is Most Beneficial for Your Gas Compression Project

Parts & Services

-

Cat® Engine Lifecycle

Learn More -

Customer Value Agreements for Oil & Gas

Learn More -

Digital Services for Oil & Gas

Learn More -

Gas Compression Training

Learn More -

Finance and Warranty for Oil & Gas

Learn More -

Parts and Repair Options for Oil & Gas

Learn More -

Cat® Reman Solutions for Oil & Gas

Learn More

Sustainability

About

As gas compression operators contemplate sustainability goals alongside their operational metrics, determining the type of engine to use for a given project—rich-burn or lean-burn—involves important considerations. Below are some key areas to contemplate when making your decision.

Lambda is the ratio between the amount of oxygen in a combustion chamber and the amount that must be present for perfect combustion. There are two primary combustion architectures for industrial gas engines: stoichiometric or "rich burn" with lambda around 1.0, and "lean burn" with lambda greater than 1.5.

Rich-burn engines feature:

- Higher exhaust temperatures

- Lower potential power node

- More complete fuel combustion

- Lower NOx with the use of an oxidation catalyst

The characteristics of lean-burn engines include:

- Lower exhaust temperatures

- Higher power node capabilities

- Lower maintenance intensity and longer overhaul intervals

- Better fuel efficiency

- Wider fuel flexibility

- Lower exhaust NOx without after-treatment

- Horsepower node. If a project requires higher horsepower nodes, due to lower combustion temperatures lean-burn architecture allows for increased engine displacement before critical component temperatures reach design limits.

- Fuel efficiency. Generally, as combustion gas temperature increases, the heat of the gas changes, making it less efficient at turning thermal energy into mechanical force on the piston. The lower combustion temperature of a lean-burn engine result in greater fuel efficiency.

- Fuel tolerance. Though methane molecules are very stable, the potential for premature ignition (or knock) increases as the length of the hydrocarbon molecule increases. The lean-burn architecture allows for more aggressive rating strategies with higher British thermal unit (BTU) fuels.

- Engine longevity. Fewer compromises in performance are required for lean-burn engines, especially as the size of the engine scales up and heat rejection becomes more challenging. This contributes to a longer engine life.

An engine that can meet the complete spectrum of operators’ needs, from durability to power to total cost of ownership (TCO) to sustainability considerations, depends upon unique project requirements. The right engine for a given application can provide maximum operational flexibility and reduce operating and capital expenses.

Need a deeper dive to determine which type of engine is right for your operation? Contact your local Cat® dealer for customized assistance rooted in deep oil and gas expertise. For more information, read the Rich-Burn and Lean-Burn engines article in Gas Compression Magazine.

Related Content

-

Gas Compression

Caterpillar has a solution to fill your needs for gas compression. From the broadest range available of gas engine power ratings, to a full complement of electric motors, there’s a Cat® driver to fit your application.

Learn More -

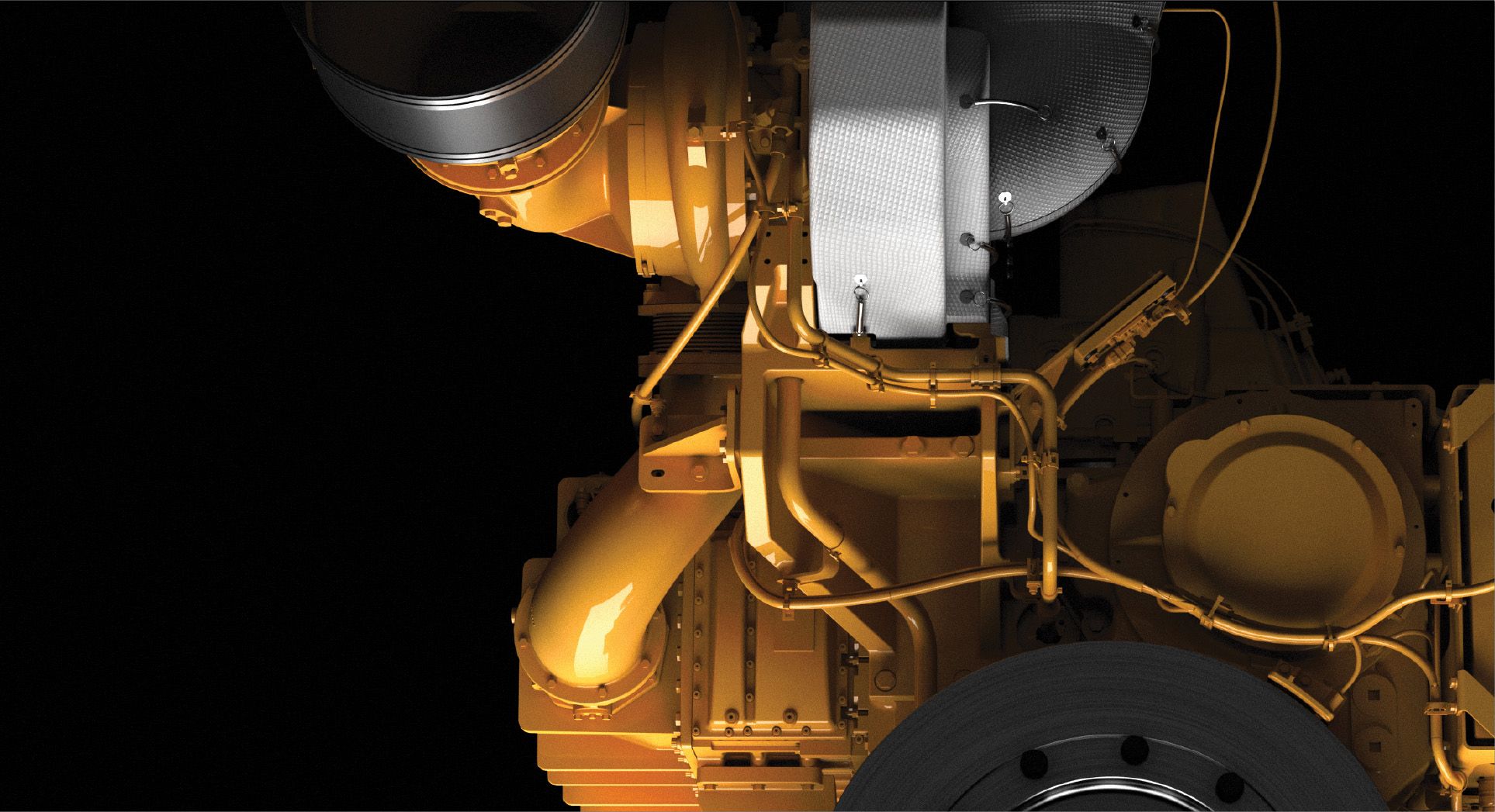

G3600 Engines

Our Next Gen G3600 engines don’t reinvent the wheel. They intelligently build on a legacy of proven success. They build on the power customers have come to trust to get the job done. They build on the reliability that’s seen them through countless days, months and years of service.

Learn More