Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

CATERPILLAR EXPERTS PROVIDE INDUSTRY INSIGHTS

Our industry is constantly changing. New regulations, equipment, tools and technology can make it hard to keep track of it all. At Tips, Tech & Tools, we bring together industry experts to share insights they’ve gained through years of construction experience.

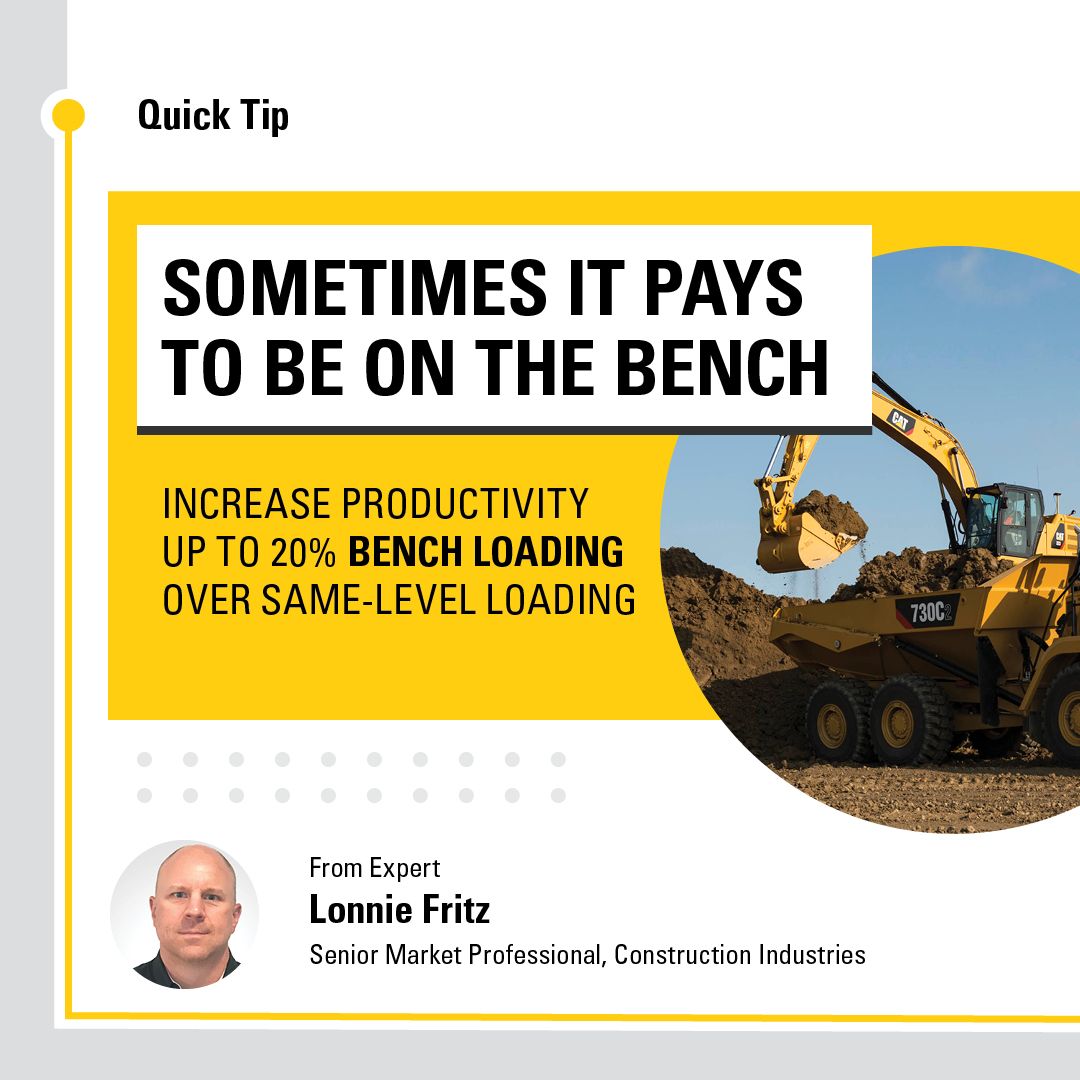

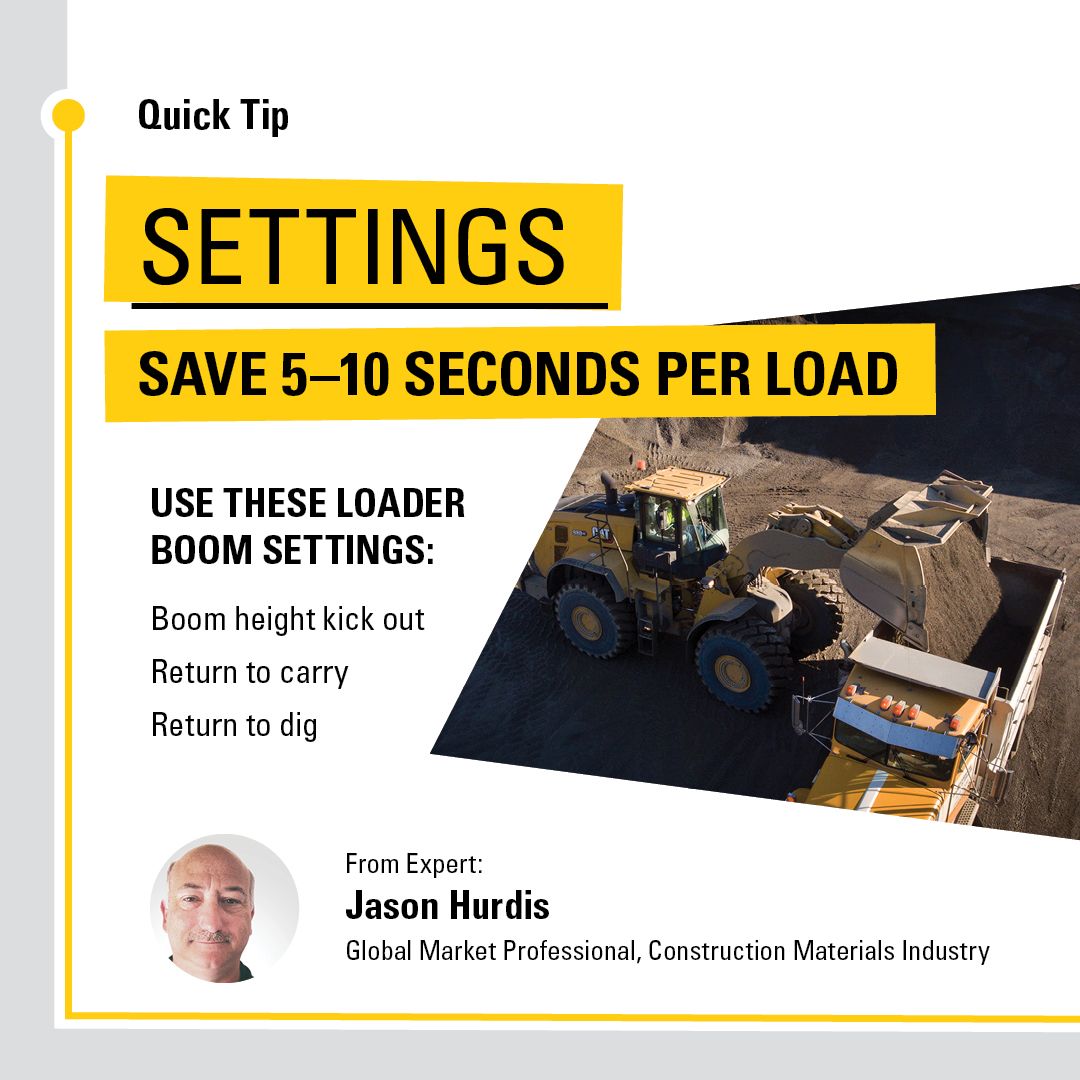

QUICK TIPS GALLERY

Improve your overall jobsite performance with expert tips that boost productivity, increase efficiency and reduce operating costs.

VIDEO GALLERY

Scroll down to find your machine family and watch these short videos from our product experts. They’ll walk you through what makes Cat® machines unique in the industry and right for your business.

DOZERS

EXCAVATORS

MOTOR GRADERS

WHEEL LOADERS

TRACK LOADERS