Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

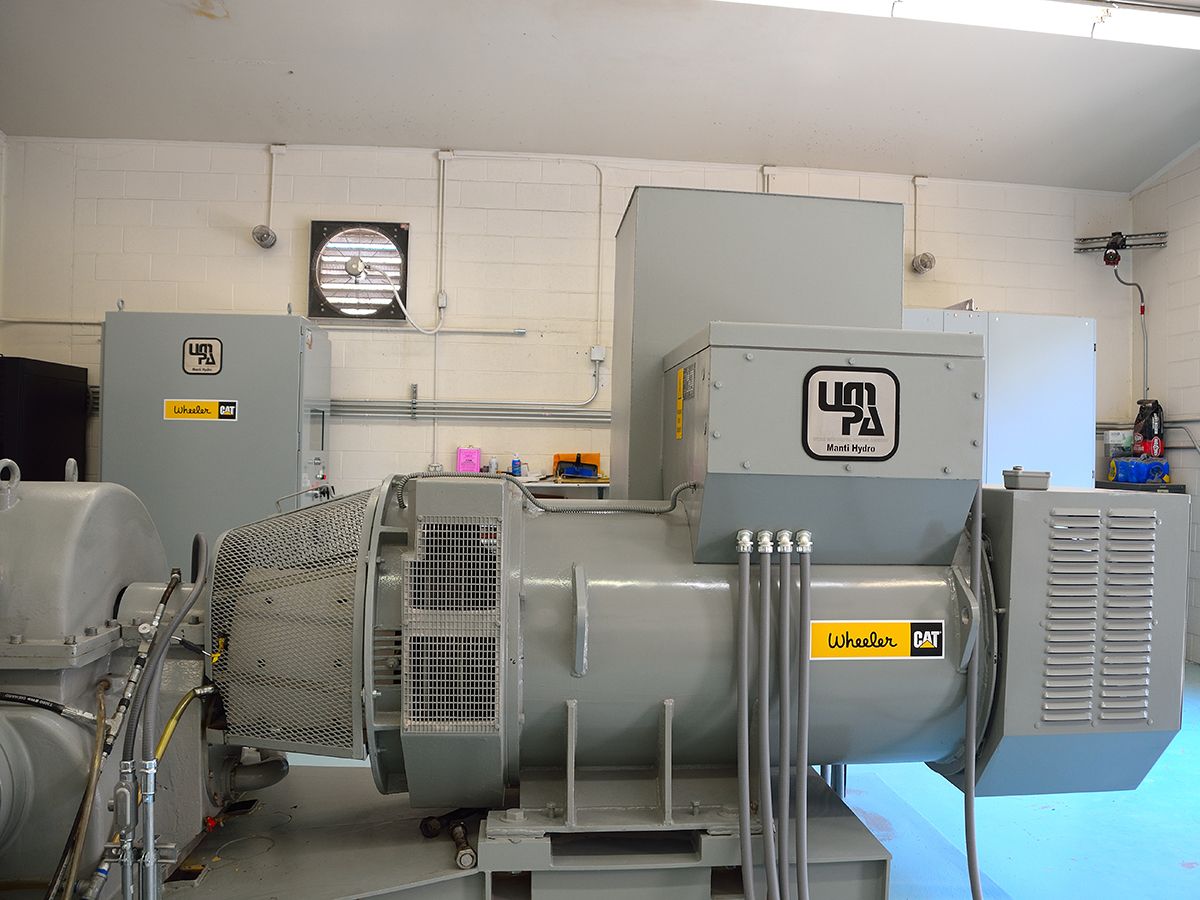

Utah Municipal Power Agency

Location: Manti, Utah

Customer Business Issue: Reliability, remote monitoring

Solution: 12,470V 1200A Cat® Switchgear with M1E Modicom Controls, custom screens with automation.

Cat® Dealer: Wheeler Power Systems

POWER NEED

In 1849, Brigham Young dispatched a company of about 225 settlers to the Sanpete Valley. They endured a severe winter by living in temporary shelters dug into the south side of the hill on which the soaring Manti Temple now stands.

Brigham Young named the new community Manti, after a city mentioned in the Book of Mormon. Manti was one of the first communities settled in what was to become Utah and was incorporated in 1851. In 1888, Manti Temple was the third Latter-day Saint temple built west of the Mississippi River.

Today, Manti has a population of 3,862 and has an agrarian economy. The town’s water supply comes from nearby Manti Mountain.

As a member of the Utah Municipal Power Agency (UMPA), the Manti Upper Plant provides hydroelectric power to UMPA. Operating around the clock, 365 days a year, the Manti Upper Plant serves as a baseload resource of energy to UMPA, while also supplying a portion of Manti’s power requirements.

The Manti Upper Plant is one of six small hydroelectric plants that UMPA operates and is its biggest plant based on kilowatt hours generated.

The water for the Manti Upper Plant is gathered about eight miles upstream through a network of springs and pipes that feed into collection points. The water eventually joins up at a single collection point know as a “head box.” From there, it is funneled into a 12-inch steel pipe that runs seven miles down the canyon through the plant. The pressure from the water coming downstream powers the hydroelectric generator.

Once the pressure and energy are removed from the water, it flows into a water tank and continues on down to the city.

Several years ago, UMPA contacted Cat® dealer Wheeler Power Systems to design and install a comprehensive overhaul of the Manti Upper Plant.

“We had a whole host of electrical issues with the plant that we just couldn’t solve, and it was getting so costly that it was becoming economically unfeasible to run the plant,” says Thomas Sorrels, an electrical technician supervisor for UMPA.

Based on an established relationship it has with Wheeler Power Systems, UMPA consulted with Wheeler and Caterpillar. After an initial investigation, it was determined that an overhaul of the plant would be the best approach.

“Wheeler helped us and worked with Caterpillar to determine a scope of work that included materials and necessary upgrades,” Sorrels says.

After consulting with UMPA and determining the scope of the project, Wheeler began the planning process, which included procuring the necessary equipment, says Jason Soares, the site project manager for Wheeler Power Systems.

“We work with Cat Switchgear to start that process on procuring those items with longer lead times,” Soares says. “We also start disassembling when it’s a retrofit like this. In this case, we took the generator and the turbine out early last fall. We went ahead and got it all refurbished and ready to go for the springtime along with the new switchgear when it was delivered. That way we could optimize the spring runoff season for the customer.”

SOLUTION

The upgrade involved refurbishing the generator end of the hydro turbine that produces electric power. Another important part of the project was upgrading the switchgear that controls the flow of energy produced by the turbine.

“Small upgrades had been made to the plant over time that were hard to document,” says Shane Minor, a sales representative with Wheeler Power Systems. “They were hard to quantify when troubleshooting was needed. So, it just made sense to come back to square one and get an engineered design in place.

“And really, the heart and soul of that is the Cat Switchgear and the controls,” Minor adds. “It’s the automation and the remote visibility that the new switchgear provides.

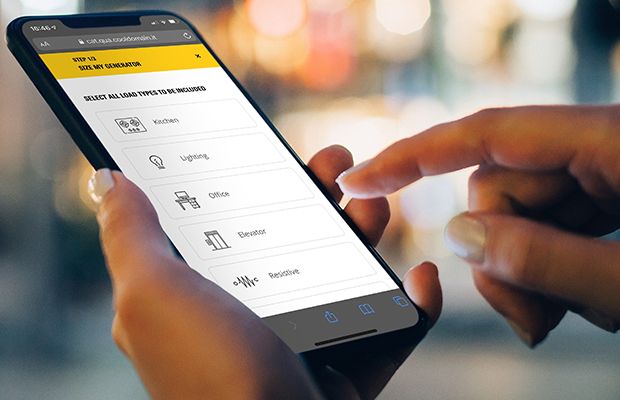

“Technology is advancing at a speed that we probably couldn’t have imagined 25 years ago. It’s progressing at a rate where it makes sense to look at making upgrades,” Minor says. “This will bring the type of functionality that they really need. For example, remote visibility to what the generator plant is doing now comes through the switchgear.

“So, not only can we bring automation to a plant through the switchgear, we can provide remote visibility, ensuring they have better protection electrically through the newest technology that’s implemented into those controls and into that switchgear.”

Wheeler received valuable technical assistance from the experts at Cat Switchgear.

“They went out of their way to undertake a project that they had really never done before, and that was to implement Cat Switchgear and controls into a hydro generation application,” Minor says. “We feel like we receive real value working with Cat Switchgear. We get the support and expertise that we feel like we couldn’t have gotten anywhere else. We get engineered design drawings that come along with the plan, so that anyone can walk in here and actually troubleshoot the plant.”

Remote monitoring is critical for UMPA because the plant is unmanned most of the time.

“We need to know if the plant goes down because we will then need to schedule more power for the area,” Sorrels says. “And for Manti City, they need to know so they can get the water to town because backup water supplies are limited in the area.”

RESULTS

Previously, Manti City employees needed to make daily trips up the canyon to make sure everything was working right at the hydro plant, recalls Blake Demill, superintendent of Manti City Power.

“We’re spending a lot less time up here because things are more automated, and they take care of themselves,” Demill says. “We don’t have to check things as often, and it’s easier to check when we do go there. It takes a lot of load off of us. This means we can take care of the things we need to do in town. It’s also monitored up in Spanish Fork by UMPA, so they can see what it’s doing all the time.”

Upon completion of the project, Wheeler personnel spent a day with Manti City Public Works employees familiarizing them with all the components that were installed as well as providing a maintenance schedule.

“We showed them how to operate it and put together a sequence of operations,” Soares says. “We went through the drawings with them and spent a lot of time troubleshooting. We simulate different scenarios so that they can work through them. By practicing with various scenarios they are likely to encounter, it increases their comfort level and confidence in the system when it’s turned over to them.”

A new protective relay monitors for overcurrent, over-voltage, and under-voltage—all of which can be detrimental in a fault situation.

“There are also things that can happen with the hydro turbine if it’s not controlled precisely during those faults,” Minor says. “So, we have put measures into place, such as instrumentation, to follow that really closely and react quickly to any kind of fault that may be on the electrical system that can take the hydro generator down.”

Going into the project UMPA officials were concerned with how the upgrade would play out, since it involved hydro power as opposed to an engine-generator set.

“But we were able to work through the process,” Sorrels says. “We spent a lot of time working with the Caterpillar engineers based on how the system used to work and upgrading it to the new, more sophisticated method of operation.

“And as they’ve done in the past on other projects, Wheeler helped us throughout the entire process, including installation, programming, and commissioning,” Sorrels says. “Then after commissioning, they worked through some of the bugs in the system and made sure that everything was in good working order.

“Now that it’s been online for awhile and really proved itself, we’re very happy with it.”