Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Best Practices for Emergency Lighting

Explore how to implement safe, code-compliant, and cost-effective emergency lighting systems.

Matt Zega, PE, RTM Engineering Consultants, Chicago

03/29/2018

Learning Objectives:

- Understand code requirements for emergency lighting.

- Learn about various approaches to emergency lighting design.

- Review best practices in laying out and selecting light fixtures.

Emergency illumination is defined as the emergency lighting within a building that is in place to light the path of emergency egress when the normal supply of power is not available, and it is a key component to the life safety system. Numerous codes outline the rigorous path to achieving a code-compliant and safe emergency illumination system. It’s vital to understand emergency lighting and how to implement emergency lighting systems that are code-compliant, safe, functional, and user-friendly.

IBC Requirements

The 2015 International Building Code (IBC) specifically requires the path of egress be illuminated at all times the room or space is occupied. The IBC maintains that the illumination levels in the path of egress must not drop below 1 fc under normal power conditions. This is not an average threshold, but an absolute minimum under normal power conditions. When laying out emergency egress lighting, the path must be closely analyzed using photometric software to ensure no point along the path of egress is less than 1 fc. On the other hand, the IBC maintains different standards for lighting under emergency power. Lighting provided under emergency power, when normal power is lost, is allowed to maintain an average of 1 fc and a minimum of 0.1 fc measured along the path of egress along the floor. Lighting levels are permitted to decrease throughout the specified time duration to an average of 0.6 fc and a minimum of 0.06 fc at the end of the required emergency lighting duration. The maximum-to-minimum lighting uniformity ratio shall not exceed 40:1.

The IBC defines any room that is required to have two or more exits as a space that must have properly illuminated aisles, corridors, stairways, and ramps. After defining how a room must be properly illuminated, the IBC goes on to describe how a building as a whole must be illuminated. In buildings that require two or more means of egress, all interior stairs, interior ramps, exterior stairs, exterior ramps, exit passageways, vestibules, and exterior landings must be automatically illuminated. The utility rooms in any type of building also must be illuminated, such as electrical equipment rooms, fire command centers, fire pump rooms, generator rooms, and public restrooms with an area of greater than 300 sq ft.

The IBC defines the amount of time required for emergency illumination at 90 minutes, whether the back-up power source is a centralized storage battery system, local unit equipment, or an onsite generator.

NFPA 101 Requirements

NFPA 101: Life Safety Code, 2018 edition, details the illumination requirements for means of egress. Starting out, the NFPA outlines that illumination shall be continuous during the time in which the conditions of occupancy require that the means of egress be available for use. The code goes on to state that artificial lighting shall be employed at such locations and for such periods of time as are necessary to maintain the illumination to the minimum criteria values.

As defined in NFPA 101, for emergency systems, lighting shall be arranged to provide initial illumination that is not less than an average of 1.0 fc and at any point not less than 0.1 fc, measured along the path of egress at floor level. Illumination levels shall be permitted to decline to not less than an average of 0.6 fc at the end of the required 90-minute period. Similar to the IBC, maximum-to-minimum illumination shall not exceed a ratio of 40:1.

In regard to automatic lighting controls, NFPA 101 describes how and when it is permissible to control emergency egress lighting. The following criteria must be considered when specifying lighting control devices.

- Lighting control devices must be equipped to turn on emergency egress lights upon the loss of normal power.

- As required for new buildings, lighting control devices must be activated by the building fire alarm system, if a fire alarm panel is provided.

- As photoluminescent signage becomes more prevalent in building design, the lighting control device must not turn off any lighting that photoluminescent signage relies on.

- Lighting control devices also must not turn off any lights that are battery-powered.

- As a whole, when using energy-saving nodes, time clocks, and sensors, the designer must ensure that these devices do not compromise the continuity of the emergency lighting system.

- Time clocks and lighting control panels must be carefully specified so that circuits do not get stuck in the “off” or open position, as this type of equipment should be specified so that the absence of power creates a fail-safe “on” or closed condition for controls.

It’s important to understand the required levels of emergency egress illumination along the path of travel. Lighting placement along walls in stairwells can pose challenges for casting the appropriate amount of light in these areas. Some light-rendering software can also make it difficult to properly model the illumination levels of a stairway. Engineers laying out lighting should be strategic in specifying fixture mounting heights to ensure the proper illumination levels are achieved.

Similar to the IBC, NFPA 101 defines emergency lighting exit access as stairs, aisles, corridors, ramps, escalators, and passageways leading to an exit. Illumination at exit discharge includes such areas as stairs, aisles, ramps, walkways, and escalators leading to a public way.

When illumination means depends on changing from one source to another, NFPA requires the delay be no longer than 10 seconds. This code excerpt refers most commonly to the reliance on generator power and the ability to automatically start a generator power source and transfer the load in the required time frame. Upon the failure of a normal power source, emergency lighting must be capable of providing illumination for 90 minutes, which is similar to the IBC requirement.

NFPA 70 Requirements

The NFPA 70: National Electrical Code (NEC), 2017 edition, defines requirements for emergency systems. Chapter 700 outlines circuit wiring and sources of power as it relates to the required emergency systems. As in the other codes already discussed, NEC also requires emergency batteries to supply and maintain loads for a minimum period of 90 minutes. The NEC further elaborates that the voltage from batteries supplied to unit fixtures shall not drop below 87.5% of the normal operating voltage.

Emergency Illumination Factors

The placement of emergency lighting, defined as the lights that will provide illumination for the path of egress when the normal power circuited is interrupted, is a critical design component of an emergency lighting system. There are many different options and factors to consider when laying out emergency lighting.

One factor to be considered is the type of lamp that will be used. LED fixtures have taken the market by storm in the past 5 years, and while other types of lamping also should be considered, LEDs will continue to be a mainstay in emergency lighting. LEDs boast a long life expectancy, leaving the facility maintenance-free for up to 50,000 lamp hours. Also, the color temperature of LED fixtures should not be a problem; LED lamping is available in many color temperatures to fit the application. One of the main benefits of LED lighting is their efficiency. Most often, this is an underappreciated feature when considering the alternative source of emergency power. Whether the fixture that will be specified is backed up on a battery, generator, or another source, an LED’s efficiency allows the specifying engineer to size those emergency power systems in a more reasonable manner.

The major downfall of some LED lights is replacing them. While the long life of an LED is a huge benefit, it also can be seen as a detriment when approaching the life expectancy of a fixture, and replacement becomes a major task. Whether the driver or circuitry of the LED lamp becomes defective or the LED lamping merely exceeds its life expectancy, the replacement of lamping on some LED fixtures can be tricky and more laborious than swapping out a fluorescent lamp. This is something to consider when laying out the emergency lighting and more so in selecting the fixtures, given some fixtures may have unique lamping options that can assist the maintenance staff in maintaining the proper illumination throughout the life of the building. It’s also recommended to review warranties and lamp expectancies closely, as there have been many instances where cheaper LED products hit the market with less-than-promised life expectancies, giving LEDs a bad reputation while also making it difficult for maintenance staff to maintain the designed illumination when fixtures are failing prematurely.

Sources of Emergency Power

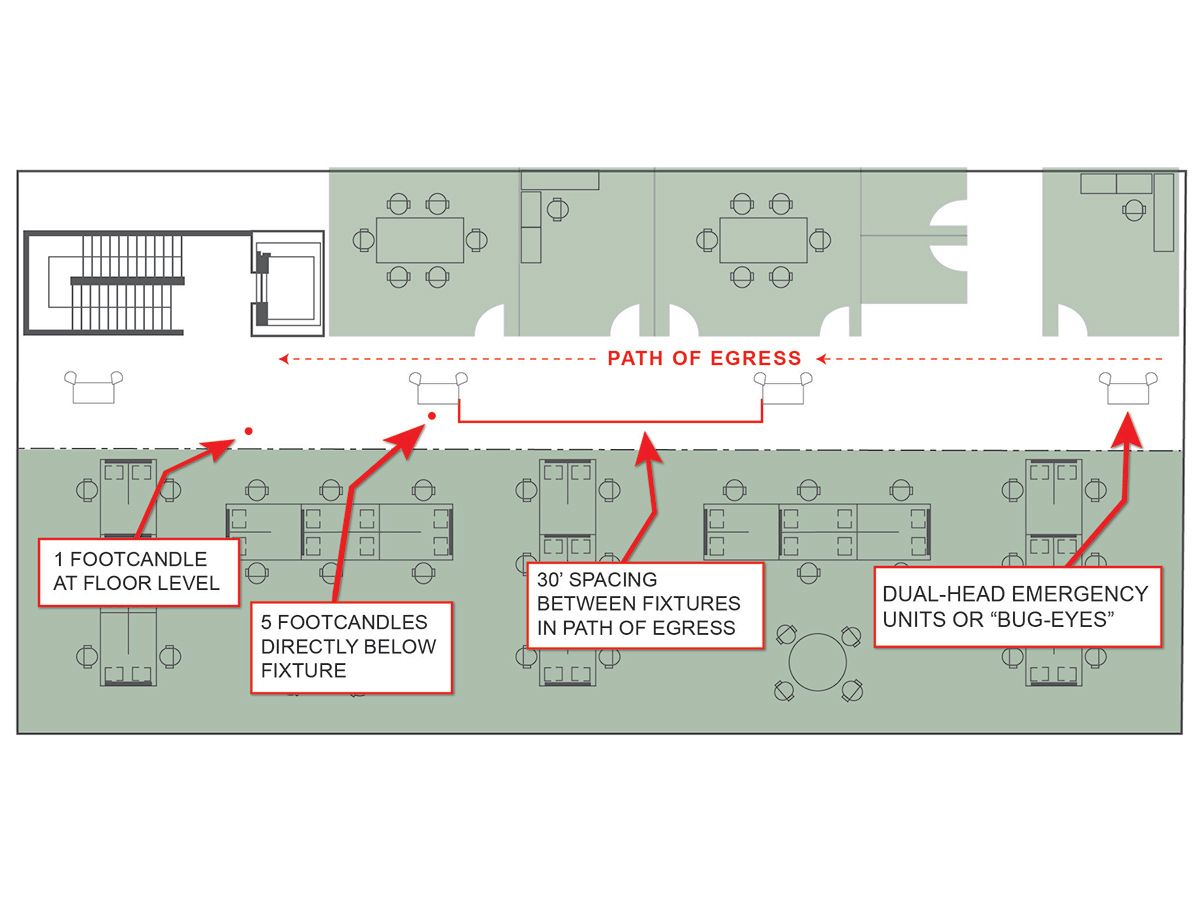

There are many different sources of emergency power to consider when designing an emergency lighting system. The most common type of system used in budget-friendly projects are dual-head emergency units, sometimes referred to in slang terms as “bug-eyes” (see Figure 1). These fixtures are simple for a contractor to connect to the local branch circuit, as outlined in the NEC, without adding a great deal of extra emergency infrastructure. These fixtures are connected to the local branch circuit in the event of a power failure and illuminate when normal power is lost. The internal battery illuminates the dual heads providing emergency lighting. One of the downfalls of these types of fixtures is that every fixture needs to be tested and maintained, creating many points of testing and maintenance. Even when a test switch shows the lamps light up initially, a full test on these fixtures must be conducted to verify fixtures are capable of outputting the intended light levels while also maintaining the appropriate voltage to the fixtures throughout the specified time frame.

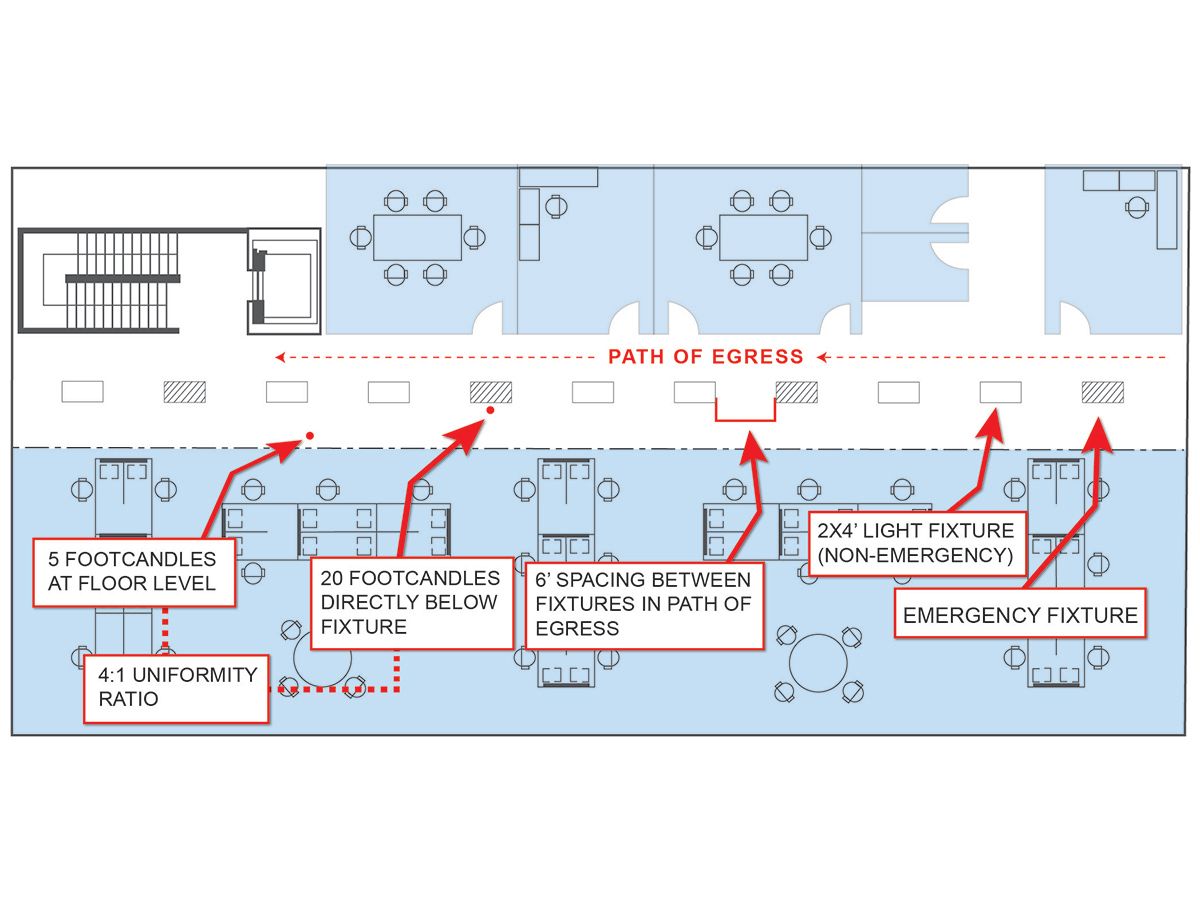

One alternative to specifying dual-head emergency battery units is to provide an emergency lighting uninterruptible power supply (UPS). The benefit of specifying and installing an emergency lighting UPS is that there is one central battery system to maintain in lieu of many fixtures scattered throughout the facility. Given the right application, an emergency lighting UPS system can be just as cost-effective as installing dual-head emergency battery units to provide emergency egress lighting. Many times, the cost of purchasing many dual-head emergency battery units can offset the cost of purchasing one central emergency lighting UPS. From a cost standpoint, the make-or-break decision between battery units and a central UPS many times comes down to the emergency light’s conduit, wiring, and switching scheme. These factors rely on the type of space and how it is laid out. How the space is configured will depend on how the lights will be switched. Having a large open space could give way to a UPS-type system, in that it will simplify the circuiting over having many small independently switched areas requiring emergency lighting.

Having an emergency generator as a power source is another consideration, and it is sometimes a requirement depending on the type of occupancy. Whether natural gas, diesel, or propane, one of the main benefits of having an onsite emergency generator is that the power being delivered can last for a much longer duration than any battery system. Having a generator connected to a natural gas supply allows for a highly reliable source of energy to keep a generator going, as compared with battery sources that are usually intended for 90 minutes of emergency illumination. It should be noted that, per the NEC, a generator acceptable to the authority having jurisdiction (AHJ) means something shall be provided to automatically start the generator upon failure of the normal power supply and automatically transfer loads for all required electrical circuits. One of the main drawbacks of natural gas can be the lack of reliability during a true natural disaster. Maintaining that fuel-source connection during a disaster must be considered, which is why parts of the country in seismic zones susceptible to potential earth damage to buried lines require alternative fuel sources, such as diesel. Diesel fuel is another popular fuel source, but even diesel can have its drawbacks. Large diesel day tanks are meant to store fuel to maintain power to a facility for days. Specifying engineers should consider factors such as fuel life. Storing large amounts of diesel fuel for extended periods of time can pose problems, as fuel degrades over time. Having a fuel-refilling contract is another component to discuss with a client to ensure the proper measures are being taken for emergency illumination.

Matt Zega is an associate with RTM Engineering Consultants. He has been designing electrical power and lighting systems for more than 12 years, and his diversified portfolio encompasses projects within all major market sectors.