Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

TOUGH AS ALL GET-OUT

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- CBI does not build machines for trade shows but for harsh conditions. Their grinders are built for high performance, a long life and the lowest cost of ownership.

- The CBI 6400CT Horizontal grinder/chipper, powered by the Cat® C27 and C32 industrial engines, is incredibly versatile with four interchangeable rotors. This allows it to go from a chipper to a grinder in less than a day, so customers can finish jobs more efficiently and be cost conscious.

- Another feature that keeps 6400CT customers on the job is the T-Link remote fleet monitoring system, which makes it easy to track location, maintenance, fuel burn and more — and also aids CBI in troubleshooting.

- Choosing an engine to power the 6400CT came down to two main factors: horsepower and customer demand. At 1050 and 1200 horsepower, the C27 and C32 can move massive amounts of material through the grinder quickly. The Cat dealer network provides the dependability and extensive service network that customers want.

- Most of the 6400CT grinders sold today feature U.S. EPA Tier 4 Final/EU Stage V engines. The fact that neither the C27 nor C32 requires the use of diesel exhaust fluid (DEF) is a big bonus and so is the fact that there is no need to sacrifice power to meet emissions standards.

Cat® Engine Overview

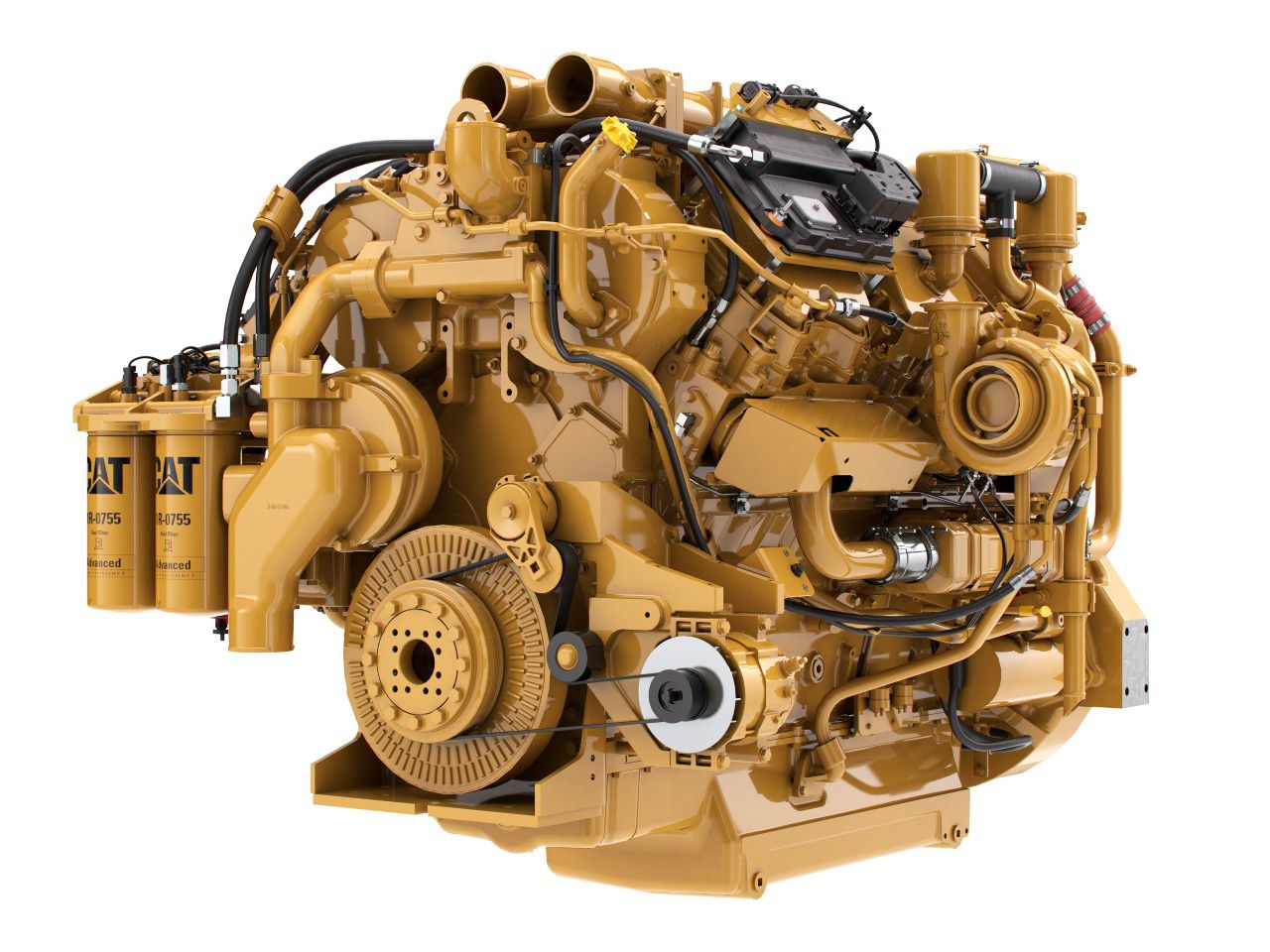

Cat C27

- The Cat® C27 Industrial Diesel Engine is offered in ratings up to 1050 hp (783 kW) and peak torque 4674 Nm (3451 lb-ft). The power-dense Cat C27 is a fully-configurable common core engine that makes installation across a wide variety of applications simple.

- With options like rear-mounted turbos and engine-mounted aftertreatment, it's now easier than ever to install. And because the C27 is DEF-free, there's even more room to maneuver under the hood.

- Featuring a clean emissions module, the Cat C27 uses DOC-only technologies to keep the engine — and the air around it — cleaner, not only making for a more efficient machine, but also a safer job site. Available as remote mounted aftertreatment for great flexibility or optional engine mounted aftertreatment for ease of installation.

- Dual certified U.S. EPA Tier 4 Final/EU Stage V offers a single installation globally for all countries requiring EU Stage V or similar emissions standards. U.S. EPA Tier 2 equivalent ratings available for countries that permit this level of emissions.

- Superior dealer service and support, scheduled maintenance and a five year warranty: it’s what Cat C27 owners network can expect with their new engine.

CAT C32

- The Cat C32 industrial engine is offered in power ranges up to 1200 hp (895 kW) and peak torque 5500 Nm (4056 lb-ft) and allows for platform downsizing while maintaining reliability and durability.

- The C32 engine is ideal for tough industrial and construction applications such as dredges, chippers, grinders, emergency water pumps and rock drills among other applications requiring continuous peak performance under the most demanding conditions.

- The key to success for any machine is avoiding downtime as much as possible. Thanks to the DEF-free, dual-can DOC with transparent regeneration offered by the 32 engine, operators can stay focused on being productive for the long haul.

- When it comes to making the engine installation process smoother for Original Equipment Manufacturers (OEMs), look to the C32 engine. Using innovative technology solutions, the C32 was created to eliminate the need for thermal management and Diesel Exhaust Fluid (DEF), reducing the size of the overall engine package. And thanks to flexible aftertreatment mounting options, installing such a large engine just got a lot less complicated.

- Optimized to meet some of the most demanding operating cycles of just about any machine, the DEF-free Cat C32 helps owners and operators save on operating costs while also remaining maintenance-free for the engine's lifetime.

Compare Models

-

- Maximum Power

- 800 HP

- 597 kW

- Maximum Torque

- 2736 lb-ft @ 1300 rpm

- 3710 Nm @ 1300 rpm

- Emissions

- EU Stage V

- EU Stage V

C18

Learn More -

- Maximum Power

- 1050 HP

- 783 kW

- Maximum Torque

- 3448 lb-ft @ 1200 rpm

- 4674 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C27

Learn More -

- Maximum Power

- 1200 HP

- 895 kW

- Maximum Torque

- 4056 lb-ft @ 1200 rpm

- 5499 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C32

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

CBI Magnum Force 6400CT Horizontal grinder/chipper

LOCATION:

Newton, New Hampshire

SCOPE OF ENGINE USE:

Cat® C27 and C32 U.S. EPA Tier 4 Final/EU Stage V Industrial Engines

DEALER:

LOGGING THE HOURS

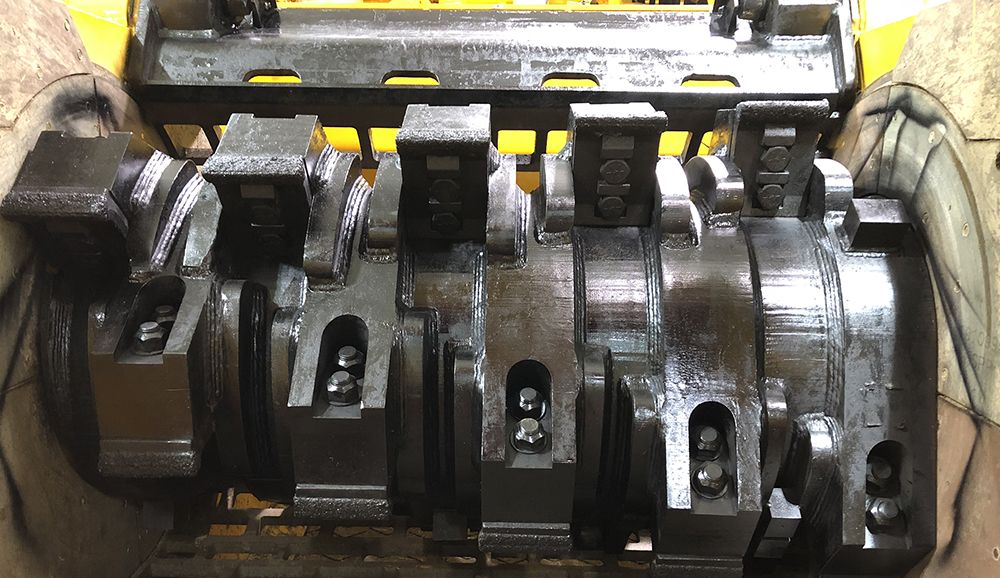

Outproduce. Outperform. Outlast. Every grinder CBI makes must live up to these high expectations. It’s a tall task for machines charged with processing everything from construction and demolition waste to whole trees and even fully assembled railroad ties. But over the course of 30-plus years, CBI grinders have proven their mettle, amassing 5,000-10,000 hours plus in some of the world’s most violent, high-vibration applications.

“Any machine can look good at a trade show, but we don’t build our products for trade shows,” says Joe Gallagher, CBI’s marketing manager. “We build them for the harshest conditions and to deliver the highest performance, longest life and lowest cost of ownership, so our customers can grow their businesses.”

That’s especially true of the CBI 6400CT Horizontal Grinder/Chipper, powered by Cat® C27 and C32 industrial engines. It’s not just a rugged machine built to process big quantities of wood. It’s also incredibly versatile. Thanks to a unique cassette-style design, the 6400CT’s four interchangeable rotors swap out faster than any other grinder in its class. “It can go from chipper to grinder in less than a day, so customers can use the same machine to bid across more jobs and win more contracts,” says Jeff Helle, product engineering lead for CBI.

Another feature that keeps 6400CT customers on the job is the T-Link remote fleet monitoring system, which makes it easy to track location, maintenance, fuel burn and more — and also aids CBI in troubleshooting. “We can log in and provide setting recommendations to further optimize a customer’s efficiency,” Helle says. “It’s like having a body on site without having anybody there. The amount of time it saves is amazing.”

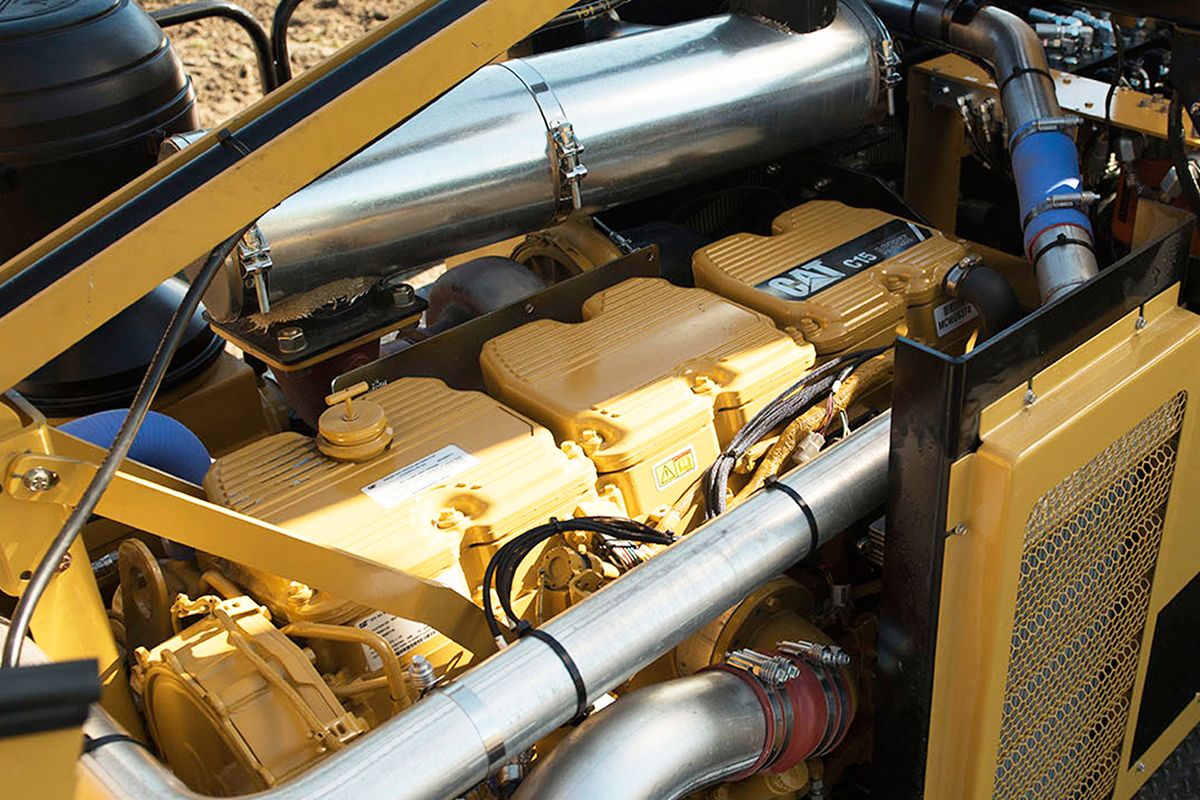

THE ULTIMATE WORKHORSE

Choosing an engine to power the 6400CT came down to two main factors: horsepower and customer demand. At 1050 and 1200 horsepower, respectively, the C27 and C32 can move massive amounts of material through the grinder quickly — delivering the throughput customers demand. And the Caterpillar name is known and trusted across the industry. “Many of our customers have a history of working with Cat engines, and they want that dependability and extensive service network for their grinders,” Helle says.

No grinding to a halt. Reliability matters because a grinder is the primary workhorse on many jobs. “If you’re clearing in a remote location, the grinder is at the center of the whole operation. If it goes down, all the other equipment on site is going to be down as well, driving up costs,” Gallagher says. With Cat engines powering the 6400CT, that’s one less worry for CBI customers. “This is one of the harshest environments you can put an engine in, and Cat engines just continue to withstand the challenge,” Helle says.

Lose the fluid, keep the power. Though CBI offers a Tier 2 engine for a few locations, most 6400CTs sold today feature Tier 4 Final/Stage V engines. The fact that neither the C27 nor C32 requires the use of diesel exhaust fluid (DEF) is a big bonus. So is the fact that there was no need to sacrifice power to meet emissions standards. “The power curve going from Tier 2 to Tier 4 Final is different, but we’re still getting maximum power out of these engines. We haven’t had any complaints about power loss,” Helle says.

Support in every neck of the woods. CBI rarely hears complaints about service after the sale, either. The company takes an all-hands-on-deck approach to keep machines up and running and expects the same for the 6400CT’s engines. CBI worked with local dealer Milton Cat to engineer the C27 and C32 into the grinder and relies on the global Cat dealer network to handle engine issues in the field. “It doesn’t matter where we sell one of these machines — there always seems to be a Cat dealer within driving distance,” Helle says.

"THIS IS ONE OF THE HARSHEST ENVIRONMENTS YOU CAN PUT AN ENGINE IN, AND CAT® ENGINES JUST CONTINUE TO WITHSTAND THE CHALLENGE."

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

W.K. Dahms Mfg. Ltd. Stone Slinger - Cat® C4.4 Engine

Learn more -

Morooka USA MST2200VDR and MST3000VD - Cat® C7.1 Engine

Learn more -

Eagle Crusher UltraMax® 1200-CC Crushing Plant - Cat® C9.3B Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

MudPuppy Pumps - Cat® C7.1 Engines

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

Paling Transporter - Cat® C13B Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

JBS Track-Pack Silage Bagger - Cat® C15 Engine

Learn more -

Rotochopper B-66L Grinder - Cat® C27 Engine

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Wolfe Heavy Equipment Trenchers - Cat® C15 and C18 Engines

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

LMR Landfill Tippers – Powered by Cat® Reman

Learn More -

Chip and crush waste with Rotochopper

Learn More

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION