Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

CAT® MINING TRUCKS

What can you expect from your Cat mining truck? The lowest cost per ton over its life.

A lot goes into delivering that value. Like high speed on grade for improved productivity. A class-leading standard payload. Anytime braking plus front and rear wheel retarding for more confident operators. Total Cat® integration, which results in highly efficient systems and performance. And high reliability, so trucks spend more time hauling material than they do sitting in the maintenance shop.

With a truck for every site and application — no matter the size class or drive system — and a broad lineup of loading tools, Caterpillar delivers a complete loading and hauling solution that delivers a better bottom line to the most important mine in the world: yours.

WHY CHOOSE A CAT MECHANICAL DRIVE TRUCK?

Next Generation Cat mechanical drive mining trucks are built with powerful enhancements that make them safer, smarter, more productive and easier to operate. Please note that these enhancements are not currently available on all models — talk to your Cat dealer to learn more about your specific needs.

Cutting-Edge Connectivity

Built For Operators

Enhanced Productivity

Improved Safety

GET THE INFORMATION YOU NEED

Fully integrated Cat electronics on our next-generation trucks include 100 Mbps, two-wire ethernet connectivity for faster data transfer and improved access to information. The future-proof technology platform includes being factory-equipped with Cat Product Link Elite™ with standard connectivity via cellular 4G/LTE and available cellular/satellite radio for reliable data transfer.

The ability to access and analyze accurate, real-time data enables faster diagnostics and enhances the ability to predict and prevent machine failure, improving availability. A new telematics platform promotes better data acquisition and faster transmission to locally hosted or cloud-based applications such as Cat MineStar Solutions.

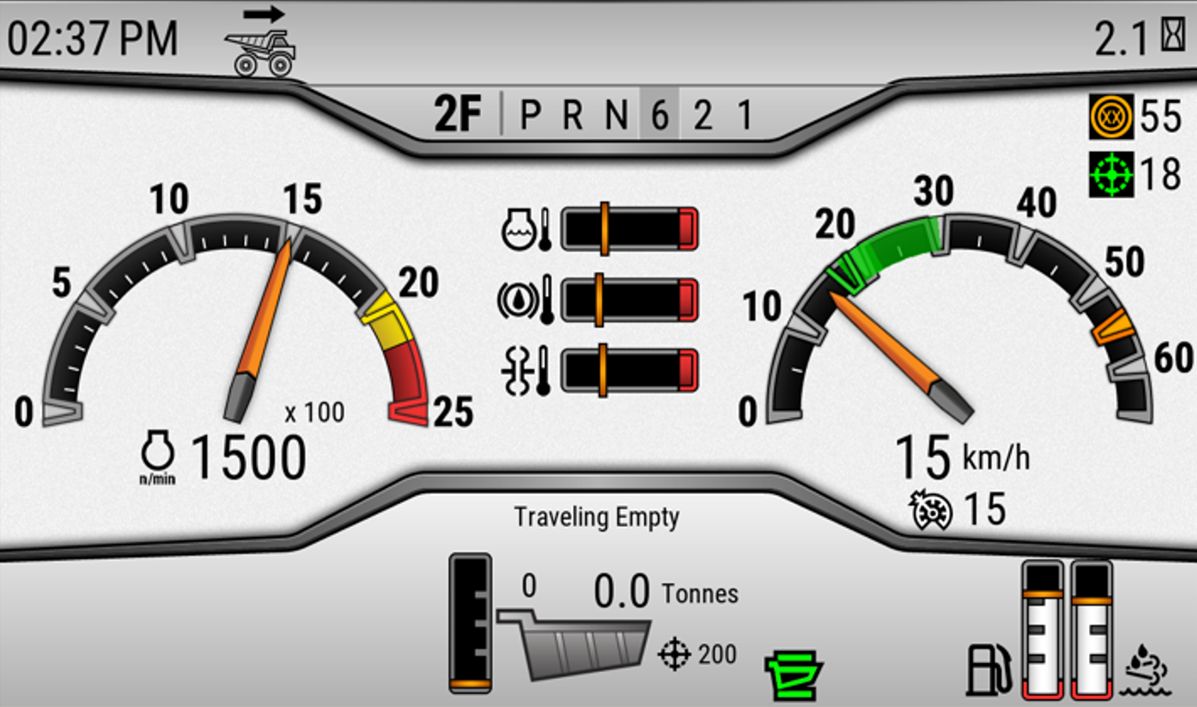

A PRODUCTIVITY-BOOSTING OPERATOR ENVIRONMENT

Next-generation Cat mining trucks feature a state-of-the-art cab designed for efficiency and equipped with features that can automate functions to help operators work more efficiently. It gives operators improved access to critical information, and includes a number of features that increase comfort and reduce fatigue.

- Push-button secure start

- Cruise control

- Speed coaching

- Machine speed limiting

- Enhanced ARC

- AutoHoist

- Improved payload monitoring

HAUL MORE EVERY LOAD AND EVERY CYCLE

We built the next generation of Cat mining trucks to be stronger, faster and more reliable than ever before. A wide variety of improvements, upgrades and features combine to deliver faster cycle times, longer component life, reduced fuel burn and the lowest cost per ton.

SAFETY BUILT IN

The next generation of Cat mining trucks is designed to be safer for operators, technicians and everyone else on site. We've improved operator visibility, braking, access and egress, service access and more with a wide array of standard and optional features all designed to do one thing — keep your people safe.

WHY CHOOSE A CAT ELECTRIC DRIVE TRUCK?

Our electric drive trucks are built to help you get more out of your machine. With powerful integrated and optional technologies, improved serviceability and increased safety, these machines can help you lower costs and increase productivity across your whole operation.

Integrated Technologies

Product Link™ Elite

Serviceability

Safety

CAT TECHNOLOGIES ON CAT TRUCKS

We take a holistic approach to technologies on our trucks, building them from the ground up for smooth, easy integration with the machine. The results speak for themselves — fully integrated and optimized machine systems designed to help you get more out of your truck. Our truck technology solutions are built using similar controllers and all software is designed by the same engineering group for maximum consistency and portability, resulting in a solution that delivers the results you expect from any Cat product.

We offer technologies that increase the performance of both the machine and the operator, as well as coaching to help operators make the most effective possible use of the tools at their disposal. And we're always pushing the boundaries, using faster and better means of communication and control to help customers better keep track of the performance and condition of their machines.

GET THE INFORMATION YOU NEED

Fully integrated Cat electronics include 100 Mbps, two-wire ethernet connectivity for faster data transfer to improve access to information. The future-proof technology platform is factory-equipped with Cat Product Link Elite™ with standard connectivity via cellular 4G/LTE and available cellular/satellite radio for reliable data transfer.

The ability to access and analyze accurate, real-time data enables faster diagnostics and enhances the ability to predict and prevent machine failure, improving truck uptime availability. A new telematics platform promotes greater data acquisition and faster transmission to locally hosted or cloud-based applications such as Cat MineStar Solutions.

KEEP YOUR MACHINE RUNNING

Cat trucks are designed to be faster, easier and cheaper to maintain — all with the goal of helping you lower your cost per ton. It's easier than ever to service the engine, drive alternator and other systems thanks to the open engine access and platforms, while ground-level filters and service points help technicians work faster and safer.

All hydraulics are located on one frame rail with cables and electrical wiring on the other, making it easier to access and service the right parts of the machine. The modular design of the machine allows technicians to service the engine, drive alternator, wheel motors and final drives, inverter IGBTs, and radial grid quadrants independently.

All trucks are fully integrated, with each component, software, system and engine designed and manufactured by Caterpillar. That means the entire machine is optimized for a lower cost per ton with systems that work together to meet your needs. And each machine is backed by the support of the global Cat Dealer Network, ensuring world-class support that meets your needs wherever you are.

KEEP YOUR PEOPLE SAFE

Safety is your top priority, and we design our trucks to help you ensure the safety of everyone on your mine site. A wide variety of standard and optional safety features help keep your operators, service staff and other personnel safe while they work on or around your trucks.

From improved operator comfort and visibility to increased control, our trucks improve safety in a number of ways large and small.

DRIVEN FOR RESULTS

With reliable performance, game-changing technologies, industry-leading autonomy solutions and reduced environmental impact, our next generation mining trucks are built to deliver the results you need.

These upgrades are currently available on the 785, 789 and 793 — and this design philosophy will guide us as we produce new models in the future.