Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Up and Crushing

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- The Eagle Crusher UltraMax® 1200-CC Crushing Plant offers closed-circuit crushing and screening on one chassis and is a popular alternative to multi-unit systems, because it’s less expensive, requires less maintenance and is easy to transport.

- Eagle Crusher customers who use equipment in one location often power it electrically or with a generator set, but those who move crushers from place to place or don’t have access to electricity choose diesel-powered products. For the last several years, that’s included the option to select Cat® industrial engines. The UltraMax® 1200-CC crushing plant comes equipped with a 455-horsepower Cat C9.3B engine.

- Fitting Eagle Crusher’s products with a made-to-order Cat industrial engine package — one that includes an engine enclosure and add-ons such as custom air cleaners — requires close collaboration with their Cat dealer. The dealer’s engineering team works with Eagle Crusher to establish horsepower and space claim expectations, then identifies the right engine package and refines the product to fit the defined requirements.

- Engine meets the latest US EPA Tier 4 Final and EU Stage V emissions requirements.

- Cat engines live up to Eagle Crusher customers’ high expectations for efficiency, reliability and after-sale support through the global Cat dealer network.

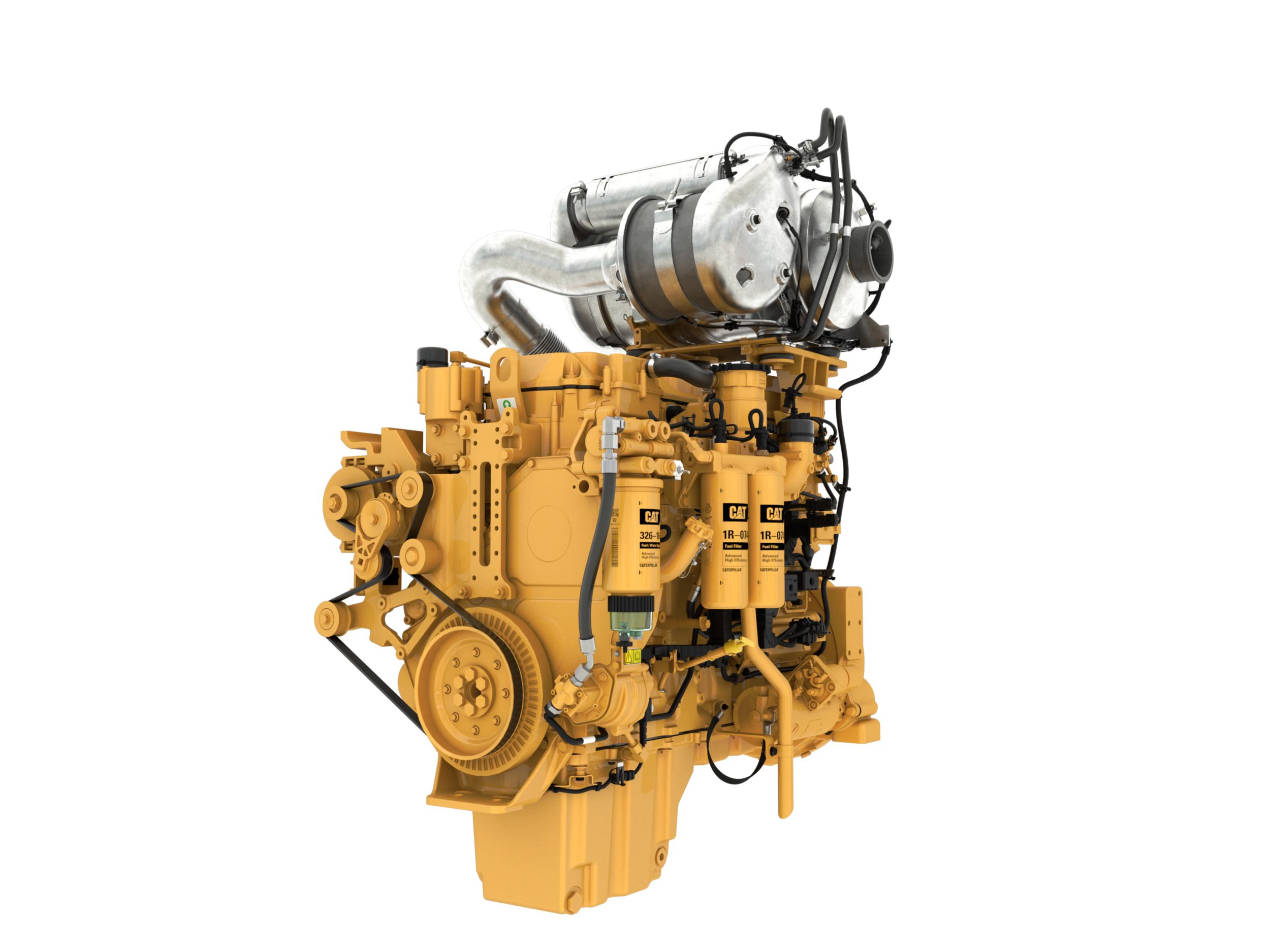

Cat® Engine Overview

- The Cat C9.3B industrial engine is offered in power ratings up to 456 hp (340 kW) and peak torque 1810 Nm (1335 lb-ft) allowing for platform downsizing while maintaining Caterpillar reliability and durability.

- Engine is over 12% lighter while offering 18% more power and 21% more torque than previous engine models.

- The engine combines a new high pressure common rail fuel system and advanced aftertreatment technology to produce exceptional power density.

- The C9.3B provides the exceptional power Eagle Crusher equipment requires in the toughest job site applications and most rugged environments.

- Cat engines also maximize performance with simpler engine systems and reduced installation complexity through modular, flexible designs fit for your equipment application.

Compare Models

-

- Maximum Power

- 320 HP

- 240 kW

- Maximum Torque

- 935 lb-ft @ 1400 rpm

- 1268 Nm @ 1400 rpm

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

- U.S. EPA & CARB Tier 4 Final, EU Stage V

C7.1

Learn More -

- Maximum Power

- 456 HP

- 340 kW

- Maximum Torque

- 1540 lb-ft @ 1400 rpm

- 2088 Nm @ 1400 rpm

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

C9.3B

Learn More -

- Maximum Power

- 577 HP

- 430 kW

- Maximum Torque

- 1943 lb-ft @ 1400 rpm

- 2634 Nm @ 1400 rpm

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

C13B

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

UltraMax® 1200-CC Crushing Plant

LOCATION:

Galion, OH

SCOPE OF ENGINE USE:

Cat C9.3B US EPA Tier 4 Final EU Stage V Industrial Engine

Cat C13B EU Stage V Industrial Engine

Cat Dealer

Michigan Cat

TURNING “NO” INTO NO. 1

In the early 1900s, C.L. Woods, a distributor for farm equipment manufacturer Eagle Tractors, had an idea: Why not develop a small jaw crusher and fit it on a tractor’s power take-off to crush field stones and other materials for building farm roads? He took the proposal to his bosses, who declined. So Woods pursued the plan himself, eventually starting the Eagle Crusher Company. More than a century later, Eagle Tractors is no more –but Eagle Crusher has grown into the #1 seller of rubber-tired crushing plants in the world.

Today, Eagle Crusher manufactures a full line of portable and stationary rock crushing equipment for the aggregate, asphalt, concrete and recycling industries. The company’s heavy-duty impact crushers, crushing and screening plants, jaw crushers and conveyors support projects ranging from the demolition of single buildings to the crushing of millions of tons of material on pipeline construction sites.

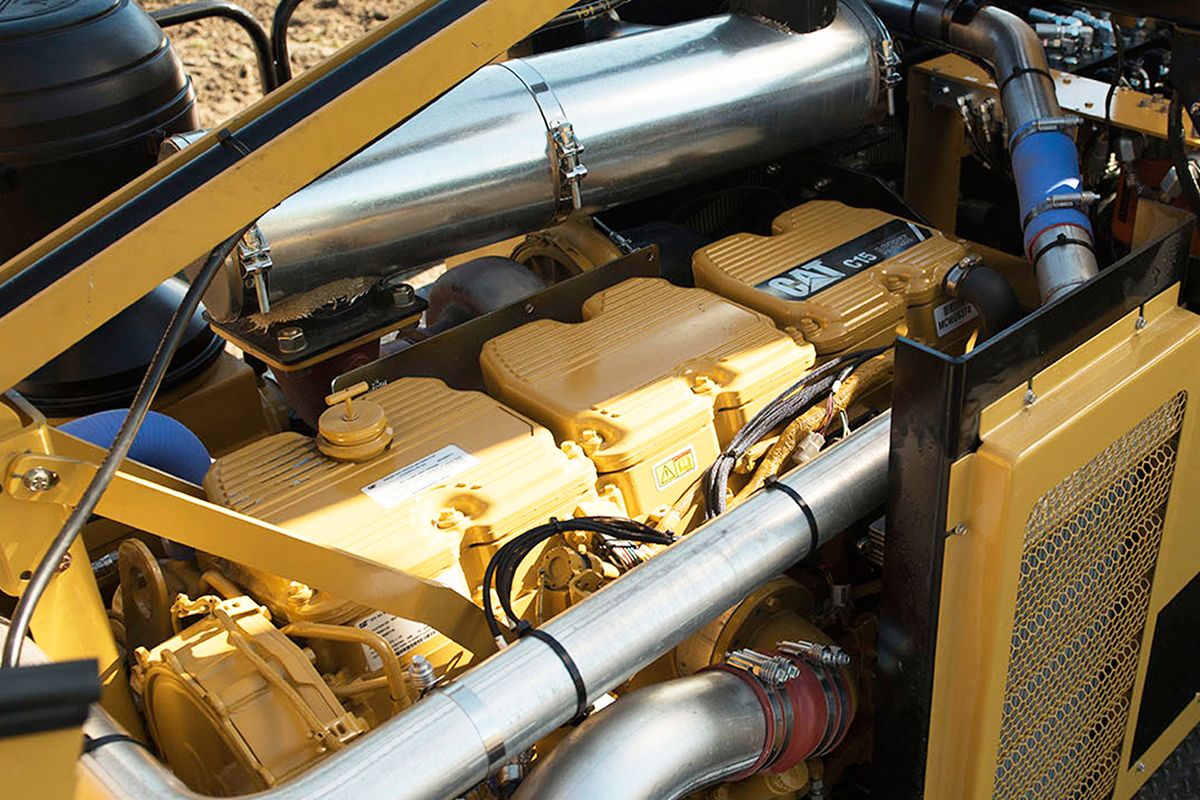

Eagle Crusher customers who use equipment in one location often power it electrically or with a generator set, but those who move crushers from place to place or don’t have access to electricity choose diesel-powered products. For the last several years, that’s included the option to select Cat® industrial engines. The UltraMax® 1200-CC crushing plant, for example, comes equipped with a 455-horsepower Cat C9.3B engine. Offering closed-circuit crushing and screening on one chassis, the 1200-CC is a popular alternative to multi-unit systems, because it’s less expensive, requires less maintenance and is easy to transport.

CRUSHING EXPECTATIONS IN A TOUGH ENVIRONMENT

“Caterpillar is an engine supplier we wanted to work with for years,” says Dan Friedman, director of marketing for Eagle Crusher. Crushing is a common task on jobsites that also rely on Cat machines, with wheel loaders, excavators and articulated trucks often used to move and haul crushed material. That means many Eagle Crusher customers are also Cat equipment owners who value commonality in their fleets or depend on Cat dealer service and support. When the inevitable failure occurs and crusher owners have to call a service rep to diagnose and solve the problem, many prefer the experience of working with a Cat dealer.

Engineering a solution. Fitting Eagle Crusher’s products with a made-to-order Cat industrial engine package — one that includes an engine enclosure and add-ons such as custom air cleaners — requires close collaboration with Michigan Cat. The dealer’s engineering team works with Eagle Crusher to establish horsepower and space claim expectations, then identifies the right engine package and refines the product to fit the defined requirements. “We also conduct prototype builds and perform installation audits to make sure everything is working as it’s supposed to work,” says Shane Patzer, OEM account manager for Michigan Cat.

Worst conditions, best reliability. In the field, Cat engines are living up to Eagle Crusher customers’ high expectations for efficiency, reliability and after-sale support. That’s no easy feat in work environments that present some of the worst possible conditions for equipment. Huge amounts of force are required to crush boulders, rocks and other heavy materials. Dusty powdered asphalt, hot sticky tar and even flying debris are common and can wreak havoc on components. “Keeping customers up and crushing is what matters,” Friedman says. “We’ve seen good reliability numbers from Cat engines.”

Opening new doors. It’s not just crusher owners who are profiting from Cat power, though. Eagle Crusher is seeing the benefits in the form of new business opportunities as well. “Having this connection with Caterpillar has given us more chances to put our products in front of potential customers,” Friedman says.

“HAVING THIS CONNECTION WITH CATERPILLAR HAS GIVEN US MORE CHANCES TO PUT OUR PRODUCTS IN FRONT OF POTENTIAL CUSTOMERS.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

JBS Track-Pack Silage Bagger - Cat® C15 Engine

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

Morooka USA MST2200VDR and MST3000VD - Cat® C7.1 Engine

Learn more -

Paling Transporter - Cat® C13B Engine

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Rotochopper B-66L Grinder - Cat® C27 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

W.K. Dahms Mfg. Ltd. Stone Slinger - Cat® C4.4 Engine

Learn more -

Wolfe Heavy Equipment Trenchers - Cat® C15 and C18 Engines

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION