Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Flex Saves with Combined Heat and Power Plants

Customer: Flex Ltd.

Location: Guadalajara, Mexico

Customer Business Issue: Cogeneration, energy savings

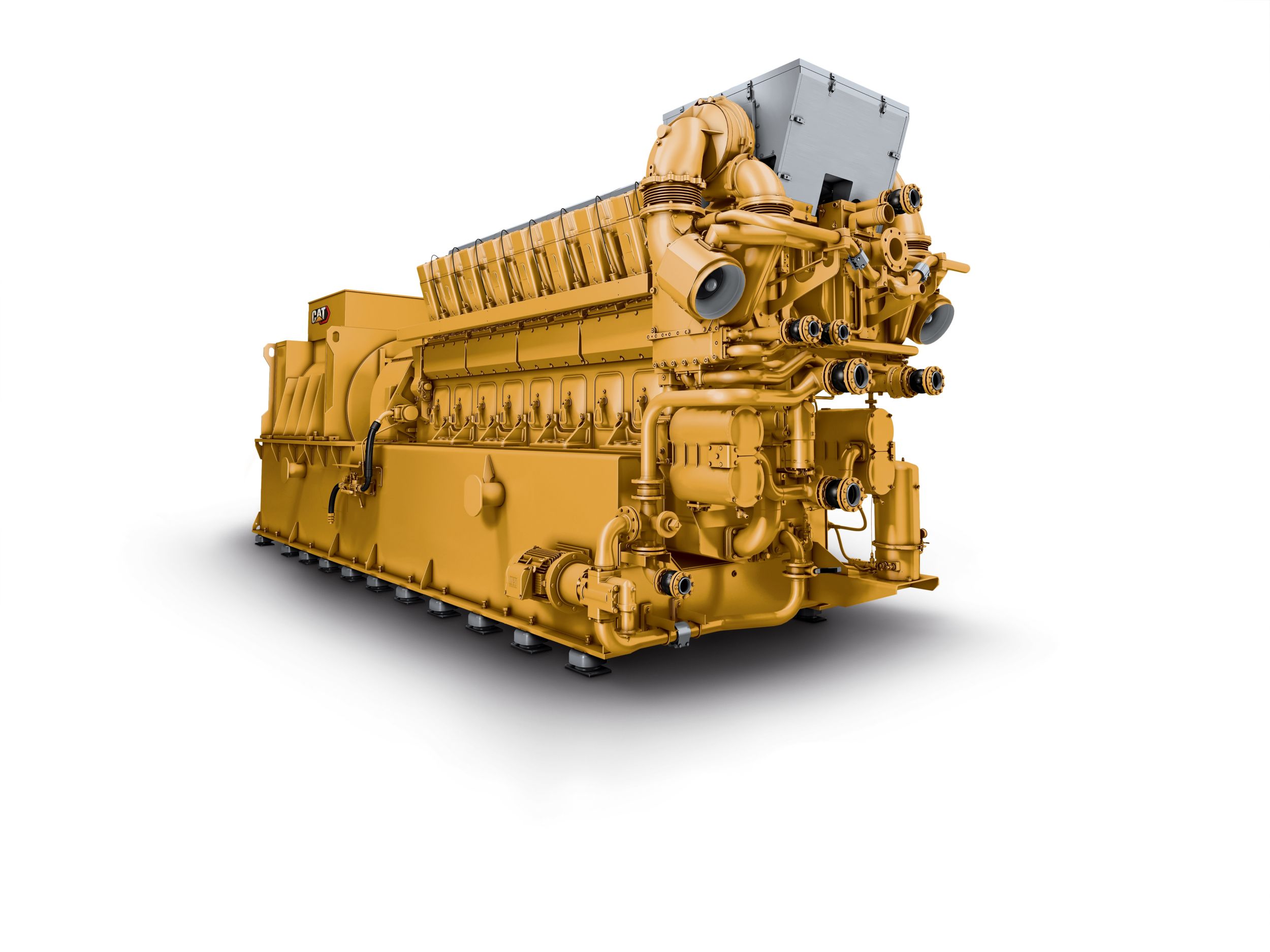

Solution: CG260-16 Cat® gas generator sets (2)

Cat® Dealer: Tracsa Energia

POWER NEED

Flex Ltd. is a leading Sketch-to-Scale® solutions provider that designs and builds intelligent products globally, with approximately 200,000 employees across 30 countries.

The company’s origins date to 1969, when Joe and Barbara-Ann McKenzie began a family business called Flextronics, making circuit boards for the growing number of companies in Silicon Valley. By automating board construction, they could produce more reliable boards faster and more cost effectively than their customers could on their own.

A decade later, the company became a contract manufacturer that customers relied upon for outsourcing not just their circuit boards, but other components and assemblies for their products.

By 1981, Flextronics became one of the first U.S. service manufacturers to go offshore by setting up a manufacturing facility in Singapore. The company realized extraordinary growth when it introduced vertical integration to optimize the supply chain. It undertook aggressive global expansion by creating industrial parks where suppliers could relocate close to where the products were manufactured. There was also a growing trend for manufacturers to acquire the manufacturing facilities of OEMs in the computer and telecoms sectors, which led to further acquisitions.

By the end of the ‘90s, Flextronics had a combined 2.6 million square feet of manufacturing space in 26 operations centers around the world. With $2.2 billion in revenue and a “who’s who” customer list in the information and communications technology industry, Flextronics distinguished itself from competitors with the ability to get products to market quickly through its multi-disciplinary new product introduction centers.

In 2007, Flextronics bought long-time competitor Solectron for $3.6 billion, putting it at the top of the U.S. market and providing the scale to help customers with any aspect of product development. In 2015, the company re-branded itself as Flex.

With its global scale and extensive physical infrastructure, today Flex provides innovation, design, engineering, manufacturing, and supply chain services to many market segments, including:

- Healthcare

- Automotive

- Heavy industry

- Energy

- Communications

- Enterprise computing

- Consumer electronics

Flex employs a total of 44,000 people in Mexico, making up 22 percent of its global workforce. It first started operations in Jalisco 21 years ago and has grown to become one of the state’s largest private employers.

In a published newspaper report in 2017, Flex’s president for global operations stressed the importance of the company’s activities in Mexico, adding that he has taken a personal interest in the growth that has been achieved in Jalisco.

“Over the years I have witnessed how Flex has become the biggest employer on this side of Jalisco and how we transformed this small operation into a place where people grow and prosper with a clear focus on doing the right thing by the environment and the community,” François Barbier said.

SOLUTION

Energy reform has been improving the country’s electricity industry by allowing private investment throughout the energy value chain. In 2016, Mexico opened up day-ahead and real-time trading in a new wholesale power market. The current electricity markets are a result of new energy laws that Mexico has implemented to open the country’s oil, natural gas, and power sectors to private participation. The power sector reforms are expected to introduce competition into the generation side of the electricity industry. It is expected that the generating facility of choice will be powered by natural gas, given the parallel reform effort to increase natural gas production in Mexico.

Foreign companies have been actively participating in investing in combined heat and power (CHP) projects in Mexico. During the next 15 years, it is estimated that Mexico will require a total investment of $123 billion in electricity infrastructure to achieve the goals set by the government. Out of the total investment, 75 percent will correspond to investment in generation infrastructure.

Located in Guadalajara, Mexico, the Flex Norte plant is a two million square-foot manufacturing facility that was established in 1996. The facility today has more than 6,300 employees and produces routers, switches, set-top boxes, servers, fiber optics, smart, grids, appliances, controllers, complex PCBAs, scanners, outdoor/indoor cabinets, 3G/4G mobile technology, and more.

A distributed energy plant at the Flex Norte plant in Guadalajara was the first CHP project commissioned by Flex in August 2014. After a bidding process, Cat dealer Tracsa Energia was awarded the project.

RESULTS

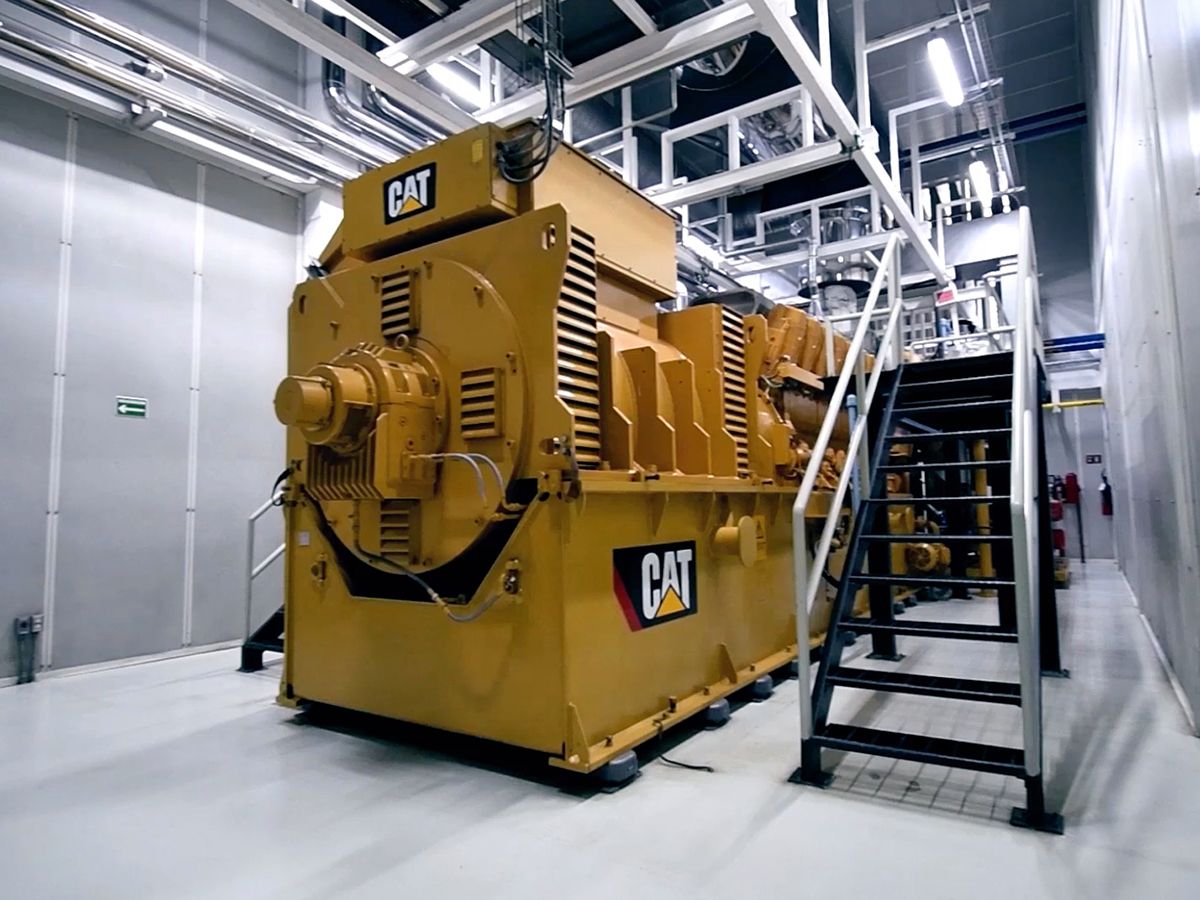

Commissioned in February 2016, the cogeneration plant has two Cat CG260-16 gensets that produce a total of 8 MW of electric power and one absorption chiller, which produces 988 tons of chilled water for air conditioning. The CHP plant was planned in two stages and has a net energy efficiency of 80 percent with the addition of the absorption chiller. The plant has operated with 99 percent availability while accumulating 33,000 hours in 45 months of operation.

“Caterpillar has become a strategic ally for Flex in terms of power generation,” said Carlos Figueroa, a senior director for Flex. “And this is extremely critical for our business because the power plant generates around 70 percent of our consumption. And what business does not currently need energy to operate?”

Payback on the Flex Norte CHP project is anticipated in less than 48 months. Based on this outcome, Flex commissioned its second CHP plant at its Tijuana facility.

In collaboration with Cat dealer Matco, Tracsa Energia is constructing a cogeneration plant that is expected to start operation in May 2020. The Tijuana CHP project consists of two Cat G3520H gensets that will help supply electric power and air conditioning to the clean rooms at Flex’s Tijuana facility. The overall energy efficiency is anticipated to be 73 percent and diminish more than 14,000 tons of CO2 to the environment.

Flex is also planning a 7.5 MW CHP plant at its Guadalajara Sur facility. The new manufacturing plant, located about 20 kilometers northwest of downtown Guadalajara, makes athletic footwear for Nike. The facility began operations in 2017 with 5,000 workers and is expected to grow to 11,000 by the end of 2019.

Overall energy efficiency at the Guadalajara Sur CHP plant is expected to be 77 percent, while diminishing some 20,742 tons of CO2 to the environment.

“An important strength of Caterpillar that differentiates them is the worldwide capacity of the Cat dealer network and their experience in engineering projects for power generation,” Figueroa said. “Without a doubt, their greatest strength is the level of customer service they offer.”

Electrical generation for private industry represents an area with enormous potential in Mexico that few companies are currently leveraging, Figueroa says.

“For Flex, the most important challenge we face is to remain competitive by the solutions we offer to our customers,” Figueroa says. “The support and experience that Caterpillar and Tracsa Energia provide us in power generation serves to help differentiate Flex from our competition.

“The business experience with Tracsa Energia has been unbeatable,” Figueroa adds. “They have become an extension of Flex.“