Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Managing Risks, Reaping Rewards through Biogas Applications

Securing success in power generation using biogas-fueled reciprocating engines

Steven J. Szymanski

Caterpillar Financial Services Asia Pte. Ltd.

International Sales Manager for Electric Power, Asia-Pacific

Michael A. Devine

Caterpillar, Electric Power Division

Gas Product Marketing Manager

John C.Y. Lee

Caterpillar Asia Pte. Ltd., Electric Power Division

Territory Manager for Asia-Pacific

October 2013

ABSTRACT

Many of the world’s regions stand on the threshold of substantial growth in power generation with renewable biogas fuels. Landfills, wastewater treatment plants, coal mines, food processing plants and many crop and livestock operations offer major potential as methane fuel.

Biogas-to-energy projects using reciprocating gas engine-generator sets can contribute sustainably produced electricity to the grid or for captive use, mitigating waste management concerns and destroying a potent greenhouse gas, while delivering strong economic returns. Prospects are excellent for generating profitable power with “free” fuels – while delivering social, economic and environmental benefits – so long as projects are properly planned and effectively managed.

introduction

Like any generating facility, biogas-fueled power plants require proper capital investments and sound long-term operation and maintenance regimens. In addition, unforeseen conditions and events can negate the advantage of avoiding the cost of natural gas, diesel or other traditional fuels. All risks connected with a project must be recognized and each allocated to the party best equipped to manage it. For a typical biogas project, the critical risks include:

- Feedstock supply (fuel reliability and quality)

- Revenue (power sales tipping fees, digestate sales)

- Technology (equipment track record and performance/efficiency)

- Operations (uptime, ease and availability of operation and maintenance)

- Construction (schedule, plant performance, cost)

- Credit (financing and debt repayment)

- Insurance (physical damage and public liability)

- Inflation (for both revenue and expenses)

Risks are best managed through contracts. The project owner, lender, equipment supplier, contractors and other parties must assemble a functional, reliable solution that meets financial and performance objectives.

TAPPING THE POTENTIAL OF BIOGAS

Opportunities existing for biogas development depend on locally available fuel sources and on economic, social and political trends work. National, provincial and state governments may offer a variety of incentives – such as favorably structured feed-in-tariffs (FIT), tax holidays, partial invest-ment grants, duty-free capital equipment importation and value-added tax exemptions – to promote cleaner, renewable fuels and reductions in greenhouse gas emissions. Programs for rural electrification in some nations also encourage development of small-scale energy projects in outlying areas, where renewable energy opportunities may abound.

Meanwhile, many governments are tightening environmental regulations affecting liquid waste, solid waste and air pollution from

agribusiness and other industry sectors, and are strengthening enforcement. In addition, some industry organizations may prescribe incentives and penalties related to sustainable operations.

Sources of renewable fuels are numerous and include a wide range of vegetable wastes, food processing wastes, livestock manure,

wastewater treatment plant digesters, landfills, and coal mines. Fuel from each of these sources presents its own challenges in variable volume, variable heating value, and content of impurities that must be managed to ensure that the generating plant runs

efficiently and – even more important – without unplanned interruptions (see Addendum 1).

KNOWING THE RISKS

Fuel variability is just one issue facing biogas-to-energy projects. For one, the projects tend to be relatively small – generally 1 to 10 MW – yet may have “soft costs” (legal and development fees) similar to those of much larger projects. Energy and its environmental considerations typically fall outside the core competencies of the feedstock hosts, and equity capital may be in short supply despite project risks that demand higher levels of it. This and other factors make effective risk management essential.

Feedstock supply risk

This is the number one risk factor that needs special attention. A biogas-to-energy project is unlikely to succeed if the long-term fuel supply is unpredictable or the fuel quality is uncertain. Project economics typically depend on a specific quantity of energy produced, and a resulting generator set capacity factor. A project based on, say, 95 percent capacity factor will surely fail if the fuel supply is frequently interrupted or curtailed, or if poor fuel quality keeps the equipment from operating at full rated output.

The project developer needs an ironclad, long-term contract with a feedstock supplier and should avoid situations that would allow the supplier to entertain competing offers from other feedstock users. A lender will typically require a feedstock supply agreement that extends two years beyond the loan repayment term.

Revenue risk

Similarly, a biogas-to-energy project needs a long-term power purchase agreement that binds the energy purchaser to a specific volume of kilowatt-hours (or energy) at an agreed-upon price for the duration of the term. Short-term purchase agreements or buy-as-needed contracts are generally not considered financeable unless a strong guarantor agrees to repay the loan regardless whether the electricity can be sold. A suitable contract typically includes a mandatory purchase (take-or-pay) obligation: The energy buyer cannot default on a purchase for any reason, including, for example, a malfunction of a transmission line or other facility within the buyer’s control that stops the flow of power. As in feedstock agreements, a power purchase agreement typically needs to extend two years beyond the loan repayment term.

Technology risk

Not all generating technologies are designed, manufactured, and serviced equally. It is incumbent on the project owner to select prime movers, generators and ancillary equipment with an eye toward a track record of performance in similar applications. While initial installed cost per kilowatt-hour matters to project success, proven reliability matters a great deal more. As part of due diligence, a project owner should ask all prospective equipment suppliers to offer references and data on successful projects of similar size and type operating on similar fuel. The technology provider should have both the ability and willingness to provide a performance guarantee for a term that is agreeable to the lender.

Operations risk

The best energy generating technology’s performance is only as good as the ongoing support it receives in the field. Improper maintenance or poor operating practices can lead to unplanned downtime that puts project financial results in jeopardy. Project owners should expect an equipment supplier to have built a substantial product support infrastructure in-country. This can include remote monitoring and diagnostics, on-demand technical support, fully qualified service technicians able to respond in less than

24 hours, and a local parts stocking and distribution network that ensures prompt delivery of genuine original-equipment replacements. Large expenses such as engine overhauls should be budgeted, and most project lenders will require a reserve account for major maintenance to be established and funded over time to cover these periodic costs. An attractive option is to enter a complete operations and maintenance agreement with the equipment supplier that covers all planned service at an annual fixed cost – this usually negates the need for a reserve account.

Permitting risk

Each market has its own permitting regimen. Permits may be needed for environmental compliance, factory operations, construction, air space, noise, forestry, and various other requirements. The permitting authorities may be both national and local. It is essential to understand the permitting processes and to allocate appropriate time for them. Some countries have streamlined permitting processes for small renewable energy projects, but it is a common misconception that environmental permitting for such projects will be easy simply because they are “green.”

Construction risk

The engineering, procurement and construction (EPC) phase of a biogas project requires an experienced contractor and proven equipment and component suppliers. Critical guarantees of milestones, such as project completion date, net kilowatt power output and the fuel heat rate based on local fuel parameters, need to be secured up front. Liquidated damages should be payable for missing any guaranteed parameter and should be sufficient to compensate for the resulting additional cost or loss of power output.

For example, liquidated damages for failure to meet the completion date should be enough to cover the additional interest cost incurred during construction. Liquidated damages for heat rate should compensate the owner for the net present value of additional fuel that will be consumed for the duration of the contract. In addition, the project owner needs to have enough equity in reserve to cover a cost overrun and still complete the project.

Typically, lenders require a lump sum EPC contract that provides a complete “wrap” of the construction of the project. Payment and performance bonds (or comparable standby letters of credit) may also be required by lenders.

Credit risk

Financing is a key hurdle for any renewable energy project. The two basic forms of financing carry substantially different risks for both lender and project owner.

Balance sheet financing requires the company that owns the project to pledge, in effect, its “full faith and credit” toward it. Assuming the owner has a strong balance sheet, financing in this scenario should be relatively quick and easy to obtain: The lender derives comfort in the form of the company’s track record, assets, cash flow and profitability. That means lower risk and therefore generally a lower interest rate. However, some companies prefer not to carry energy projects on their balance sheet, operating them instead as separate business entities or contracting with third parties.

In such scenarios, non-recourse project financing is used. Here, no proven, stable parent company stands behind the payment Obligations of the project: its financial viability depends solely On the project’s own revenue, profit and cash flow. Given the Challenges of retrieving installed engines and ancillaries and the customized nature of electric power projects, even the equipment itself offers the lender little by way of collateral. Due diligence becomes much more stringent: Is a long-term power purchase agreement in place? How reliable is the supply of feedstock for fuel? Is there a supply contract in place? If so, for how long? Is the project developer experienced in the energy sector or with power generation? Because the review process is more involved and the risks greater, the interest rate and development costs generally will be higher.

Essentially, from a lender’s perspective, the difference between balance sheet and non-recourse project financing is like the difference between investing in a blue-chip company versus a startup company.

Insurance risk

The entire project must be adequately insured against physical damage and public liability for accidents, property damage and personal injury. It should also be insured against lost revenue from business interruption, such as from a storm, flood or fire.

Inflation risk

The financial model needs to include an adequate inflation factor covering both revenues and expenses. This should include inflation in construction capital costs as well as the long-term inflation that may affect operating costs, such as replacement parts, labor, rents and general expenses.

MANAGING RISKS EFFECTIVELY

Minimizing contract risks

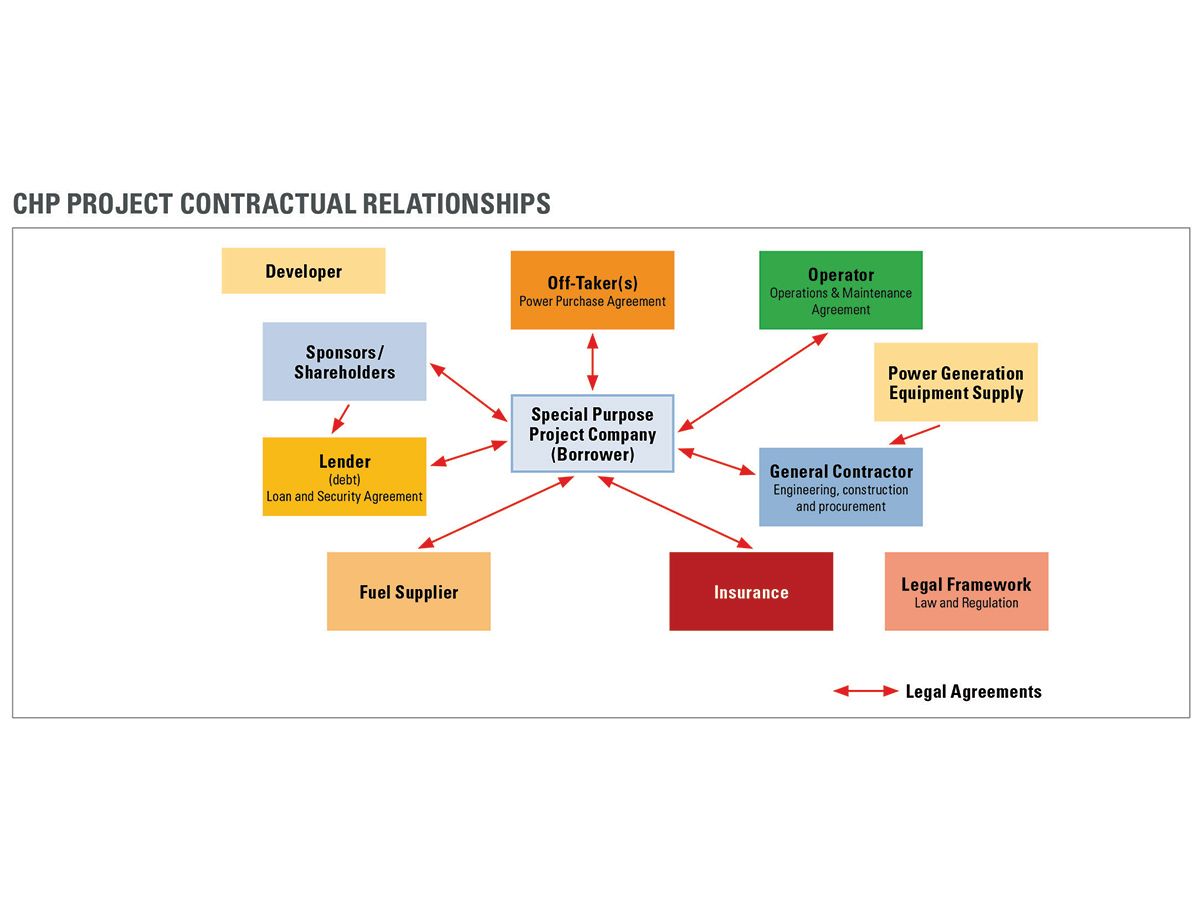

All these risks can create a complex interplay between multiple project needs and multiple players (see Figure 1). Financing for a project depends on a legal and binding framework of agreements covering all parties. Every relationship represents a risk that needs managing. In general, the more players, the greater the risks: One party’s failure to perform can undermine an entire project.

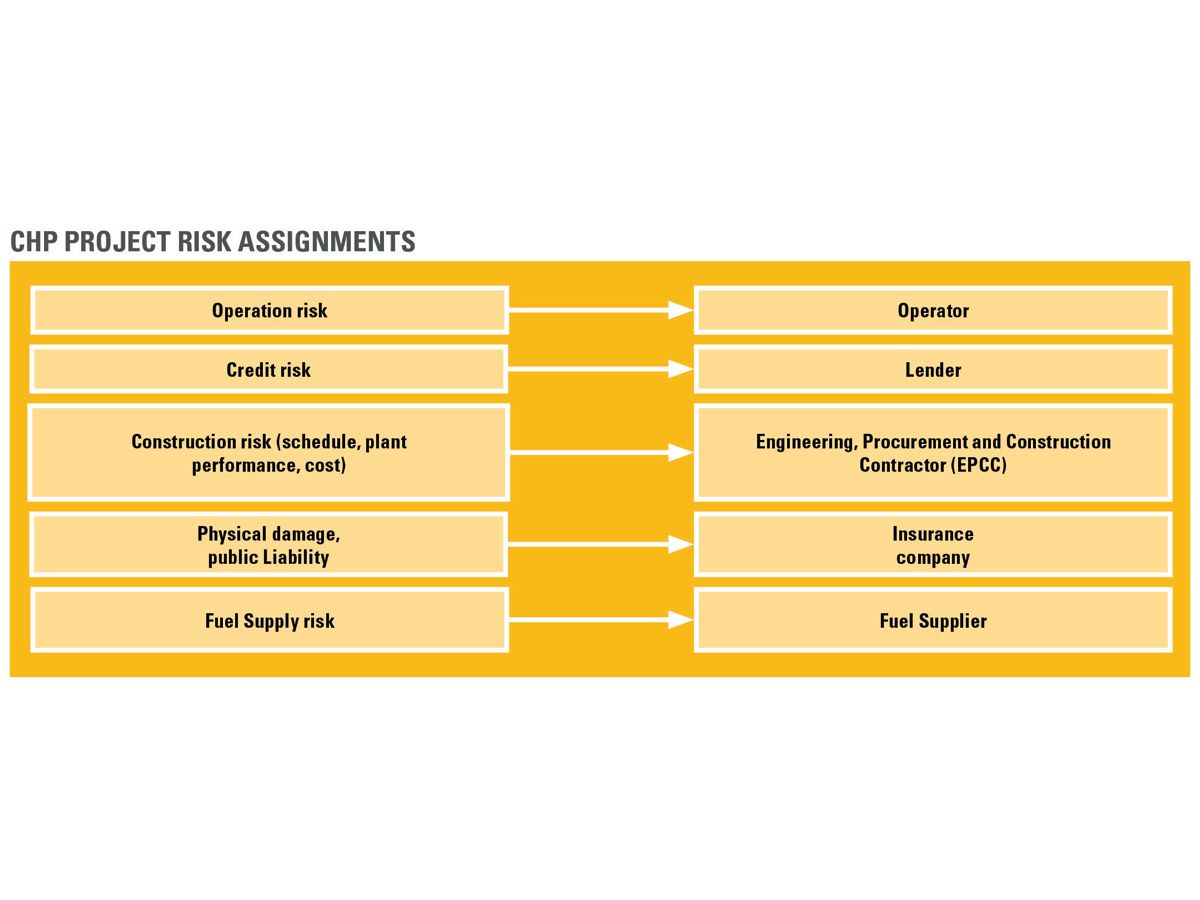

The way to manage risks is through written contracts. These contracts must assign each risk to the party best qualified to manage it (see Figure 2). All these contracts must work together without mismatches or conflicts. Several iterations of the contracts may be needed before all relationships and responsibilities between the parties are properly integrated.

Technical considerations

The technology and operations sides of biogas projects deserve special attention because such projects have different risks than power generation using traditional fuels. This is mainly because fuel volume and quality can vary from source to source, from project to project, and even within the same project over time.

The biggest variable affecting biogas project costs is fuel quality Depending on its source, biogas contains a variety of impurities that can increase engine wear and shorten maintenance and service intervals. The most common is water, found in most biogases at levels that exceed engine manufacturers’ fuel specifications.

The second most common concern is particulate matter (dust, sand, grit) in the fuel and air that causes premature component wear. The most potent contaminant is hydrogen sulfide (H²S), which is present at damaging levels in most, if not all, biogases. H²S can combine with moisture (water) to form acids and lead to significant component erosion and reduction of oil life.

Siloxanes (silicon compounds from cleaning and personal care products) are most commonly found in landfill and sewage treatment digester gas and will form hard, ceramic-like deposits on cylinder components.

Engine manufacturers and their dealers are best equipped to help project owners address these risks. Two basic approaches can be used alone or together, depending on the fuel characteristics, ambient conditions, and other considerations:

Treat the fuel

Various technologies can remove significant amounts of fuel impurities. For example:

- A chiller, demister or coalescing filter removes water.

- Fuel and air filtration is effective against particulates.

- Wet biological or chemical-biological scrubbers are effective against H²S.

- Adsorbents such as charcoal and silica gel capture siloxanes.

While effective, fuel treatments increase capital costs, add parasitic loads, and require additional maintenance materials and labor. Choosing the appropriate (economical and effective) fuel pretreatment technology is essential.

Choose a ‘hardened’ engine

Some manufacturers offer engines with design features that “harden” components and systems against biogas fuel impurities. The use of hardened engines typically requires some acceleration of maintenance and overhaul schedules. Every project is different, and approaches to fuel impurities must be weighed on a fuel- and site-specific basis.

Under certain conditions, hardened units can operate at close to normal maintenance intervals with less intensive fuel treatment. Such modifications include:

- Crankcase ventilation to eject acid-forming gases and water vapor.

- Elevated jacket water temperatures to help prevent condensation of water and formation of acids on metal parts.

- Replacement of bright metals (aluminum and unprotected steel) with stainless steel or brass on certain components.

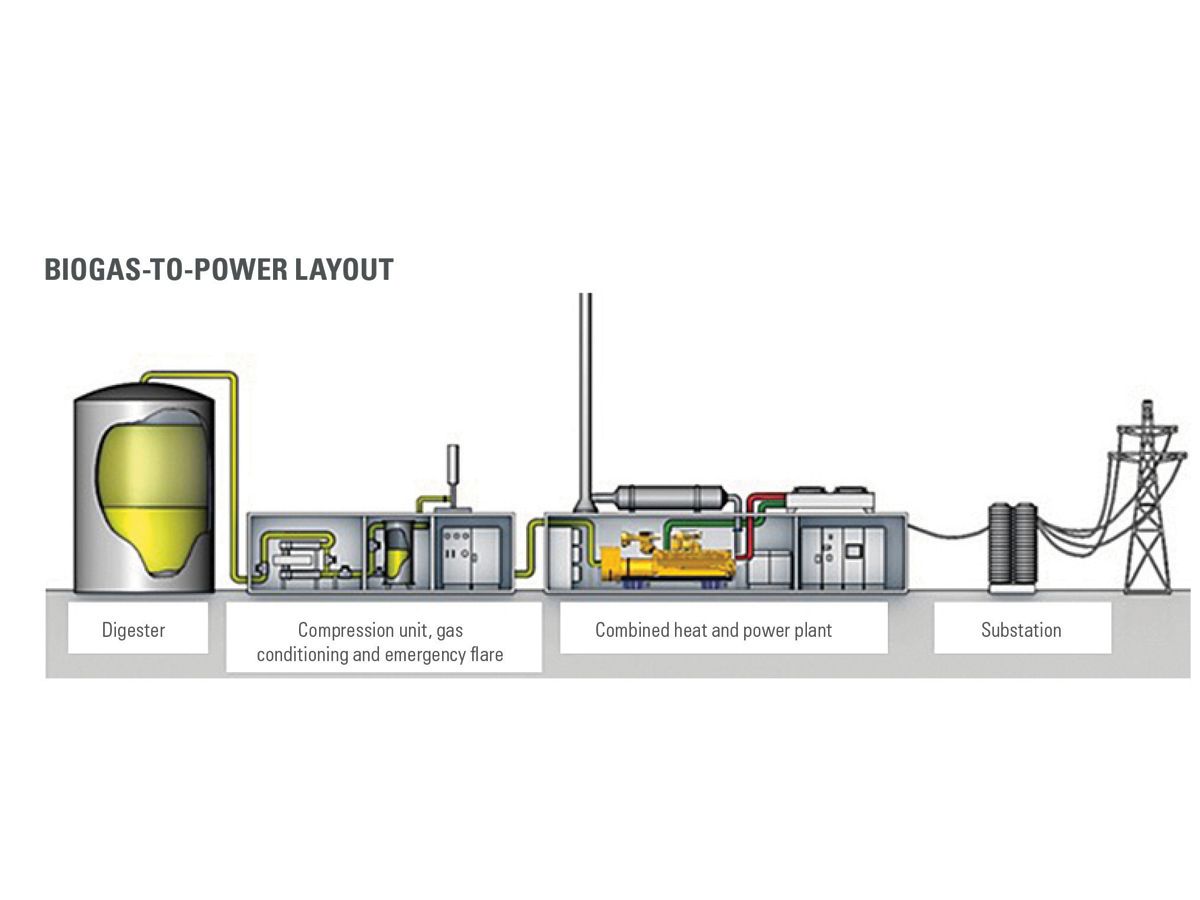

Figure 3 is a typical layout diagram for a biogas-to-power project, including an anaerobic digester, a fuel pretreatment system (scrubber, dryer, and blower), and the biogas generator set.

PROJECT ECONOMICS

After all risks are considered, the success of a biogas project comes down to economic performance, in particular cash flow. Under project financing, lenders typically require a project to generate 1.5 times the cash needed to cover the debt obligation – after taxes and all expenses – during each year of the project loan. A project lender will require a detailed financial model that clearly shows

all assumptions and follows generally accepted accounting principles to portray the project economics accurately. The model should be user-friendly to allow the lender to review various “what-if” scenarios and test the strengths and weaknesses of the project economics.

Revenue side

Base revenue amounts to the value of the net kilowatt-hours generated and sold. That in turn depends upon:

- Availability. Revenue is lost anytime the generating equipment does not operate, such as during maintenance and repairs, or at times when the fuel supply is reduced or interrupted.

- Load factor. Ideally, the generating equipment operates at full rated load; a fuel supply shortfall or a decline in fuel quality will restrict output and revenue.

- Derates. Overheating, high temperature and high altitude may keep the generating equipment from achieving its nameplate capacity rating.

Revenue also includes incentives such as government grants and tax breaks and utility-sponsored rebates or special renewable energy tariffs.

Expense side

On the opposite side of the ledger fall owning and operating expenses:

- Capital expense. This includes the cost of generating equipment, fuel production, interest during construction, legal and development costs, funding for cost overruns, interest rate, loan amortization, and management of the project schedule.

- Operating expense. This includes revenue sharing or royalties to the feedstock host, engine/generator set and facility maintenance and repairs (including engine overhauls), and taxes.

Maintenance and repairs are an expense over which project owners have substantial control. Predictive maintenance can help extend generator set service and overhaul intervals and reduce service costs by up to 15 percent. Good predictive practices include regular oil analysis to help optimize service intervals; monitoring of trends like valve recession, oil consumption and emissions to fine-tune overhaul schedules; and use of tools like vibration analysis and infrared thermography to detect trouble before failures happen.

Any economic analysis needs to consider potential revenue stream risks (decline in gas volume or quality, power line outages that interrupt power sales) and upsides (more and better-quality gas than expected, favorable renegotiation of the power purchase agreement, greater-than-expected equipment availability). A responsible approach calls for being conservative in estimating fuel volume: It is better to be forced to flare some gas at times than to risk facing intermittent shortages.

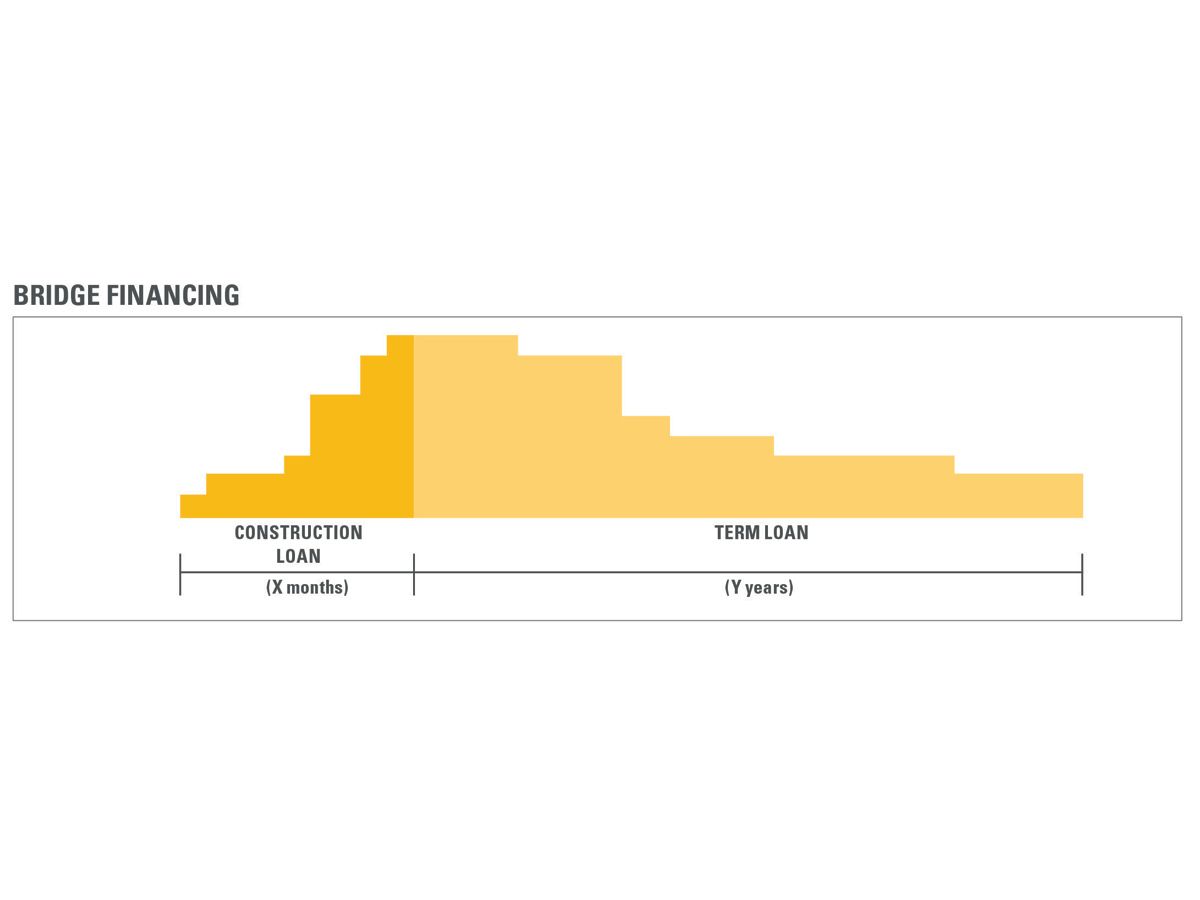

Lastly, an especially valuable attribute in a partner is the ability to provide construction financing – a form of bridge financing while the project is under construction and not yet producing cash flow. Upon substantial completion of the project, the construction loan is converted into long-term financing (see Figure 4).

PUTTING IT ALL TOGETHER

One way to simplify a biogas-to-energy project is to work with a partner well qualified to manage a number of the basic risks – such as an engine-generator manufacturer with a diverse technology portfolio, a well-developed dealer network and a strong financing arm. That partner can bring to bear:

- A variety of generating technologies in a broad range of power ratings to suit many applications. This can include engines designed specifically to operate on low-energy biofuels, and engines custom engineered for local ambient conditions, altitude, fuel quality, and site-specific performance objectives.

- In-country dealerships with broad experience in operating and maintaining power generation equipment and with locally based service technicians. Such dealers can offer a wide range of service programs, from basic planned maintenance and overhauls to comprehensive long-term service agreements.

- Dealerships able to manage whole-project engineering, procurement and construction and supply all engines and generators, plus transformers, switchgear, gas treatment systems, and other ancillary equipment.

- Diverse financing capability that includes intimate knowledge of the special needs of power projects in general and renewable energy projects in particular. This can include expertise in financing small projects ($5 million or less); knowledge of development processes, project economics, and incentive programs in each country; capacity to finance entire projects rather than equipment only; and flexible financing approaches to suit specific customer needs.

Moving forward

Biogas-to-energy projects offer major opportunities to generate profits, enhance energy efficiency, and improve sustainability in the Asia-Pacific region. These are favorable times for operators in agriculture, food processing, wastewater treatment, solid waste management and other industries to explore the full potential of producing electricity with renewable fuels.

ADDENDUM 1

IT’S ABOUT KILOWATTS – AND HOURS

In assessing the performance of a biogas-to-energy project, the equipment’s efficiency is important – but not nearly as important as its availability (uptime). Simply stated, anytime the generating equipment is offline, it produces zero revenue. Its kilowatts of capacity are devalued when its hours of operation are reduced.

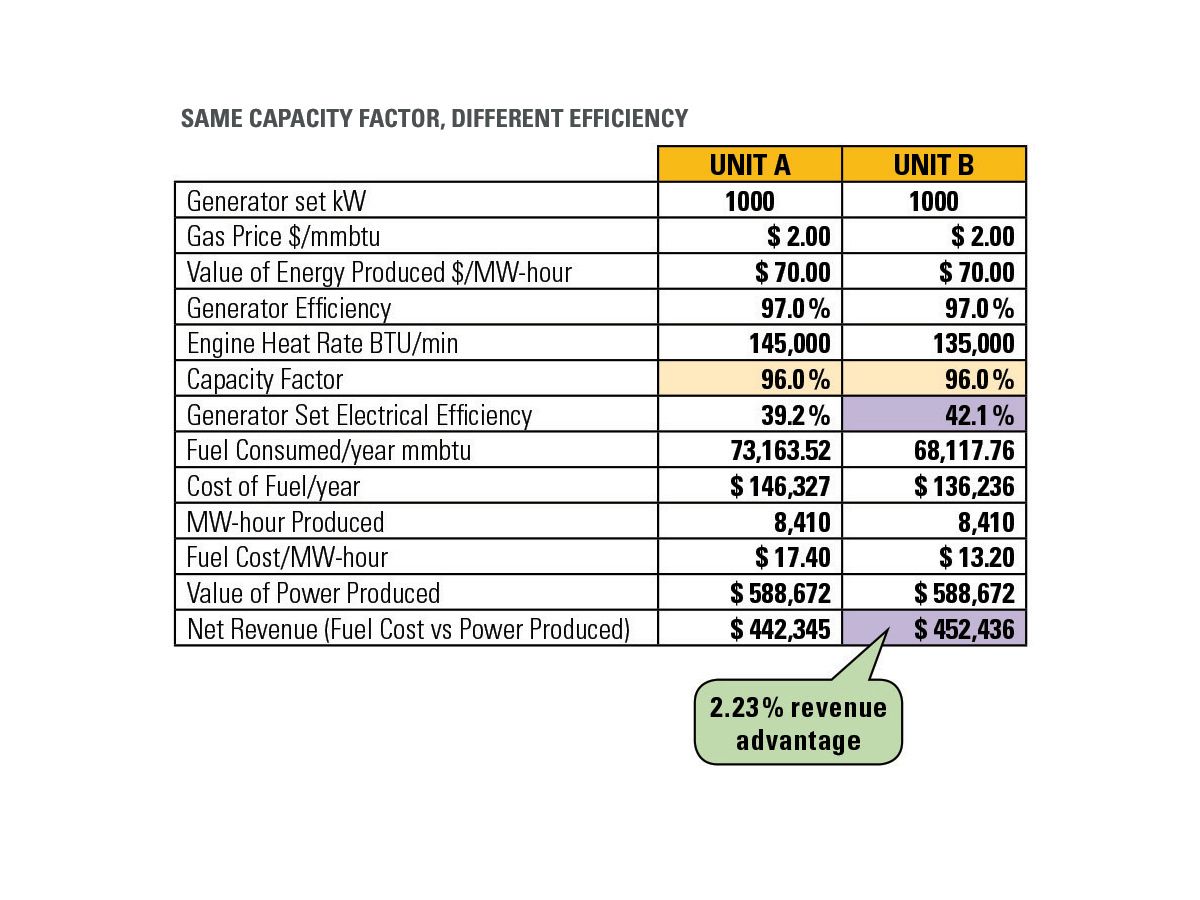

A simple scenario illustrates the tradeoff between generator set electrical efficiency and availability, as they affect revenue. Assume two 1 MW units, an electricity sale price of $70 per MWh, and a fuel production cost of US$1.90/GJ (US$2/MM Btu). Now assume that both units operate at 96 percent availability, but that Unit A is 39 percent efficient while Unit B is 42 percent efficient. In that scenario, the more efficient Unit B has a 2.2 percent net revenue advantage (see Chart 1).

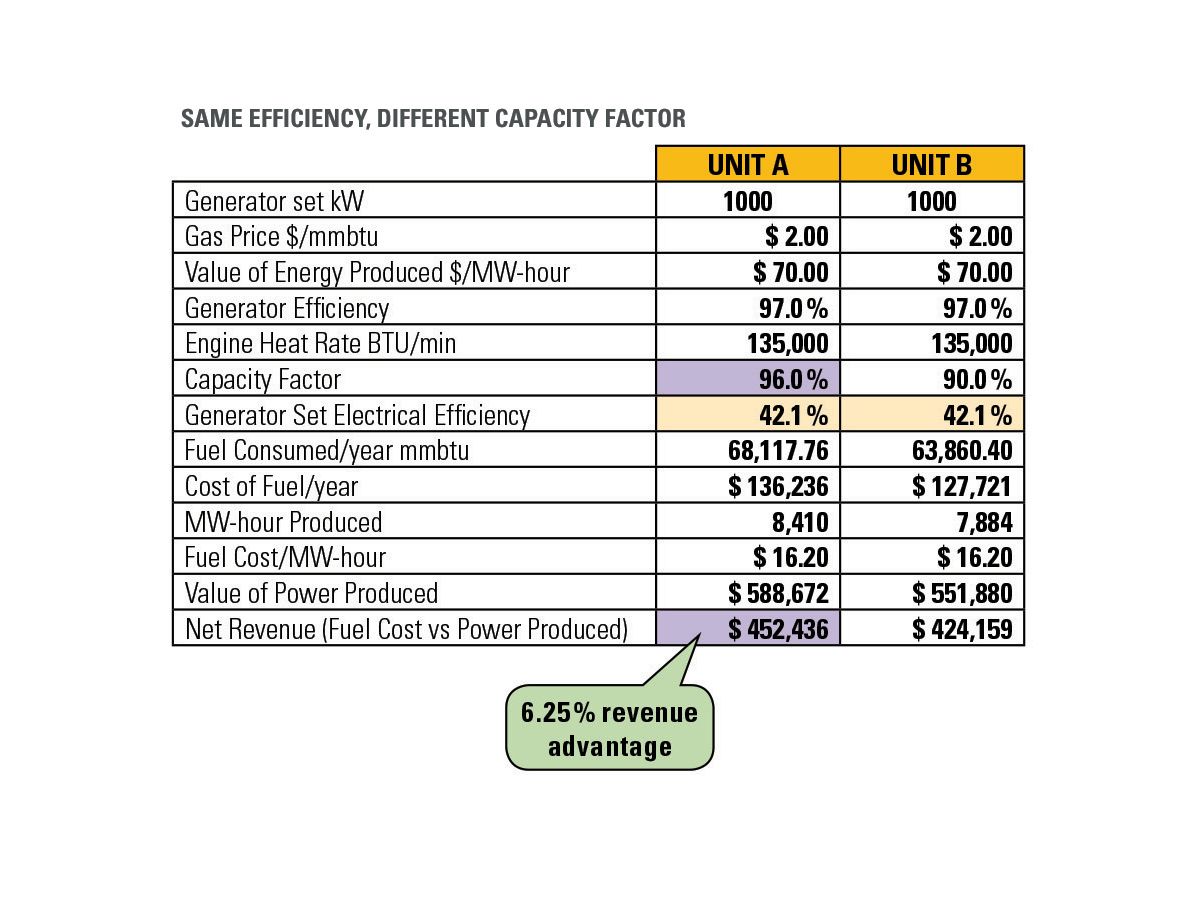

Now for the same two units, assume that electrical efficiency is the same at 42.1 percent, but that Unit A’s availability is 90 percent and Unit B’s is 96 percent. In this scenario, the more available Unit B has a 6.25 percent revenue advantage (see Chart 2).

ADDENDUM 2

BIOGAS PROJECT ECONOMICS

Every biogas project is different: No single, simple financial model applies because feedstocks, fuel volume and quality, owners’ objectives, local power requirements, and other parameters vary greatly. However, here are a few general rules of thumb:

Typical capital expense

Capital cost depends on the gas production and power generating technologies and the plant design. Estimates for 2013 in Asia are:

- For a simple covered lagoon digester with a 2 MW power plant at a palm oil mill, the total capital cost, including “soft costs”

will be approximately $4 million (US$2,500 per kW). A tank-type UASB or CSR digester can add considerable capital and operating expense. - For biomass gasification projects, capital expense is typically about US$3,500 per kW, depending project size.

- Municipal solid waste gasification projects can cost up to US$4,000 per kW.

Project economics depend on whether the revenue from sale of power is adequate to support the capital and operating costs and still provide a reasonable cash flow. A more capital-intensive technology may require a longer loan repayment term to generate enough cash flow. If the longer loan term is not supported by an even longer-term power purchase agreement, then the project may not be viable.

Financing terms

- Typical loan term: 7 years (power purchase agreement must be 2 years longer)

- Typical loan amount: 70 percent of total project capital cost

- Interest during construction: Accrued into the loan principal

- Interest rate: LIBOR plus a margin, dependent on the project risk analysis. The variable rate can be converted to a fixed rate. Local currency may also be available.

- Fees: Legal and lender’s engineer fees payable up front as billed

- Debt service reserve: Equal to six months of principal plus interest

- Cash management account with an agent bank: Collect payments from the power purchaser, pay expenses and loan payments, then issue dividends

Results

- Debt service coverage ratio not less than 1.5:1 for the duration of the loan

- Equity internal rate of return greater than 25 percent

- Simple payback less than 4-5 years