Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

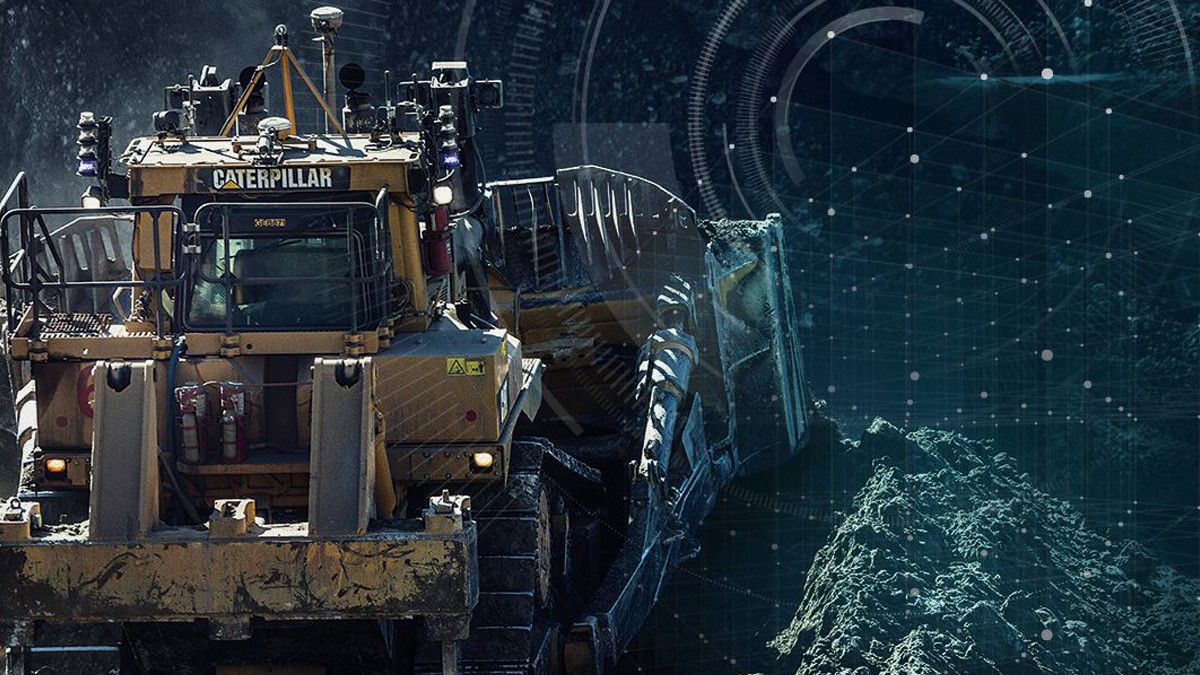

THE CAT® D10 DOZER

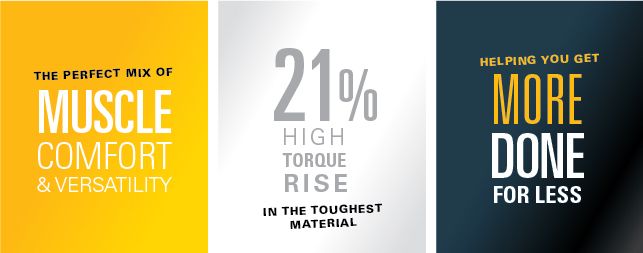

The Cat® D10 Dozer is innovative by design — developed by a team of experts who follow a design approach that incorporates feedback from the field with industry-leading technologies to deliver a dozer that continues to advance with every model. The new D10 is no exception. It’s more efficient, so it burns less fuel. It’s more serviceable, so you’ll experience less downtime. It’s more durable, so you’ll spend less over its lifetime. And it’s more productive — so you’ll spend less time putting more profitability to your bottom line.

WANT TO LEARN MORE?

WHY CHOOSE THE D10?

Onboard Technology

Product Link

Undercarriage

Safety

Cat® MineStar™ Solutions

SAVE TIME. IMPROVE ACCURACY. BOOST PRODUCTIVITY.

Cat Grade with 3D for dozing is a factory-integrated technology that uses satellite guidance to help operators grade to plan faster and more accurately. It can increase productivity by as much as 50% while reducing operator inputs by up to 80% — helping operators get more done with less effort for better performance and reduced fatigue.

In addition to Cat Grade with 3D, the D10 comes equipped with a number of standard technologies that increase accuracy, productivity and operator confidence.

GET THE INFORMATION YOU NEED

Cat® Product Link™ wirelessly connects you to your equipment, giving you valuable insight into how your machine or fleet is performing. Most new machines leave the factory with Product Link installed, but conversion kits are available for older models already in the field.

With Product Link Elite, you can stay connected to your machines and get critical data any time, anywhere. It delivers accurate, timely and useful information about the location, utilization and condition of your equipment — the kind of information that can make a huge difference in the efficiency and costs of your entire operation.

GET MORE OUT OF YOUR UNDERCARRIAGE — CAT HDXL WITH DURALINK

Our Heavy Duty Extended Life (HDXL) undercarriage with DuraLink is built tough to stand up to high-impact and highly abrasive environments and applications. Its patented design is proven to work harder and last longer, helping you drive down maintenance costs and keep your machine hard at work instead of idle in the shop. Learn more about how HDXL can extend your undercarriage system's life.

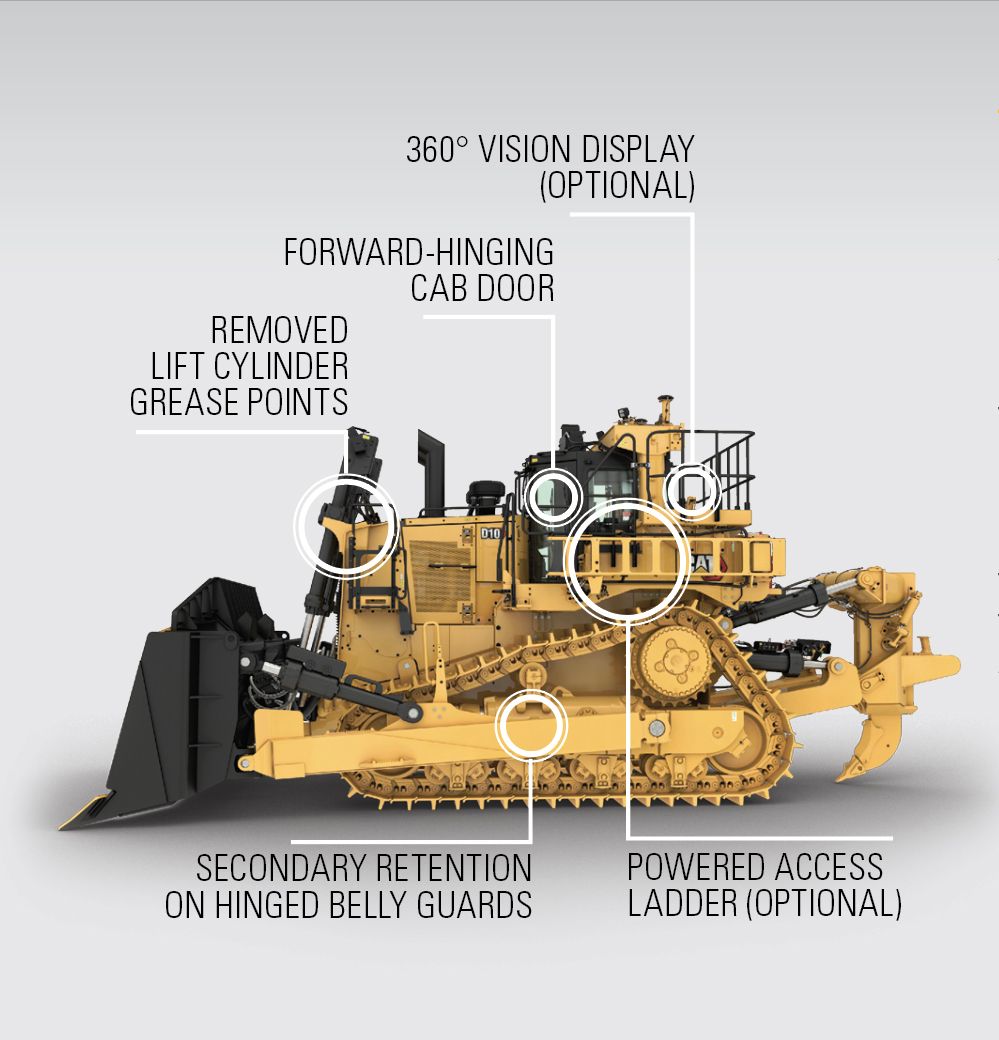

Operator Safety and Comfort

The D10 is loaded with standard and optional features to help improve the safety of your operators, service technicians and any other personnel working on or around the machine. Improved operator awareness and visibility, safer access and egress, safer service areas, a factory-installed fire suppression system and more all help you meet your number one goal — keeping your people safe.

A comfortable, spacious operator environment with state-of-the-art touchscreen controls helps combat operator fatigue and distraction and keeps your people working safely and productively all shift long.

Maximized efficiency for dozing and grading

MineStar Solutions for dozing and grading are focused on operators — providing the information they need to maximize their efficiency. They’ll have access to onboard guidance tools and real-time feedback on bench heights, cycle times, volume of material cut and filled and more. You can also incorporate remote or semi-autonomous dozing to keep operators safe and productivity high.

The D10 can be equipped with all the hardware necessary for the Cat MineStar technologies of your choice right out of the factory. Retrofit kits are also available to implement MineStar on machines already working in the field. Talk to your dealer for more information.