Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

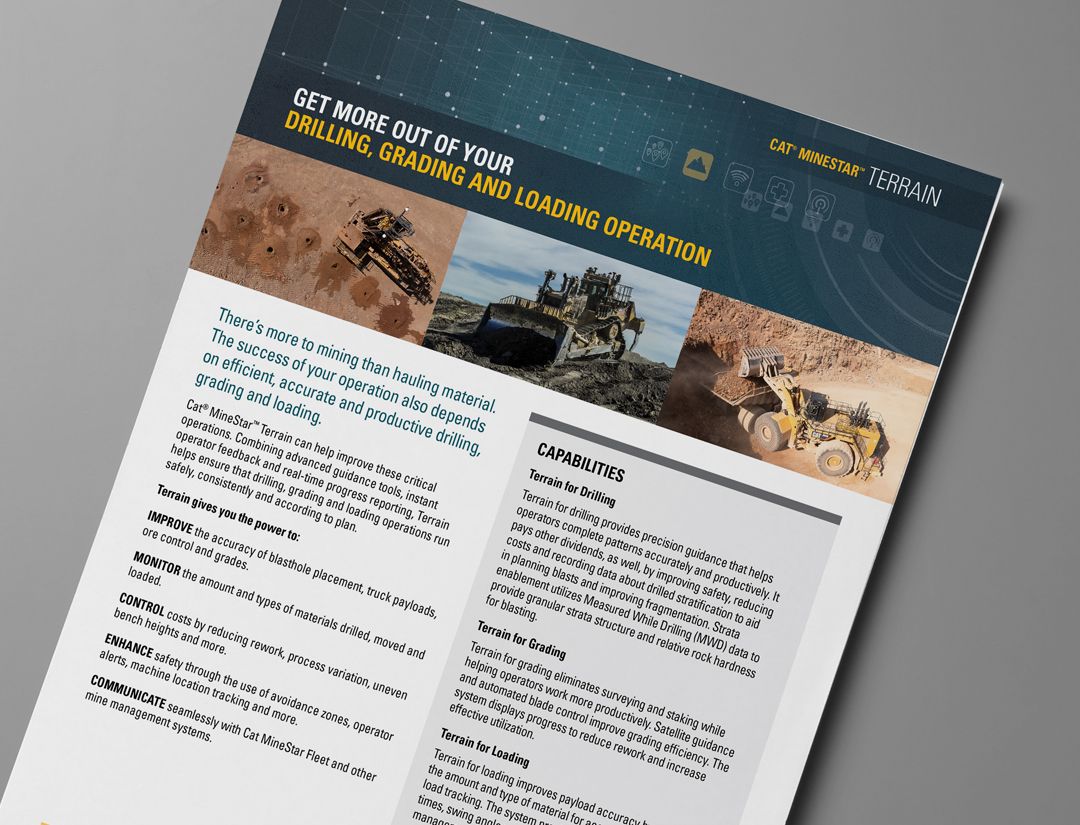

Cat® MineStar™ Terrain

Cat MineStar Terrain uses high-precision guidance technologies, material tracking and more to help your machines work according to plan — increasing efficiency, reducing variability and helping you get the most out of your drilling, digging, loading and grading operations.

Terrain’s guidance tools give your operators the confidence to work more precisely and productively. And real-time feedback lets you replicate successes and quickly correct errors. The solution helps you increase drill capacity, crusher throughput and material accuracy while driving consistency in payloads and bench heights. Plus, it works with any brand of equipment and lets you share data across your existing mine management systems, streamlining everything from drilling accuracy and blasting to ore control and site planning.