Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Curious About E-Frac? Here Are Three Factors To Consider.

Electric fracking, or e-frac, is getting a lot of press these days. It replaces a traditional frac trailer’s engine and transmission with an electric motor and electronic controls, which are powered by an electrical source — usually a gas turbine. One turbine can power eight to 10 trailers. Proponents of e-frac claim it could save a traditional fleet as much as a million dollars a month by eliminating the cost of diesel. But does the reality live up to the hype? Here are three things to keep in mind as you weigh your options.

1. The upfront expense

Buying gas turbines to power a fleet of trailers could cost you in the neighborhood of $30 million. Some turbines require pre-boosters on site to deliver gas at higher pressures, which means another outlay of cash. Compare that to the $8-10 million it will cost you to purchase diesel engines instead. Even if you end up paying nothing for the gas that powers your turbines (a highly unlikely scenario — see #2), how many years will it take to recoup your initial capital expense?

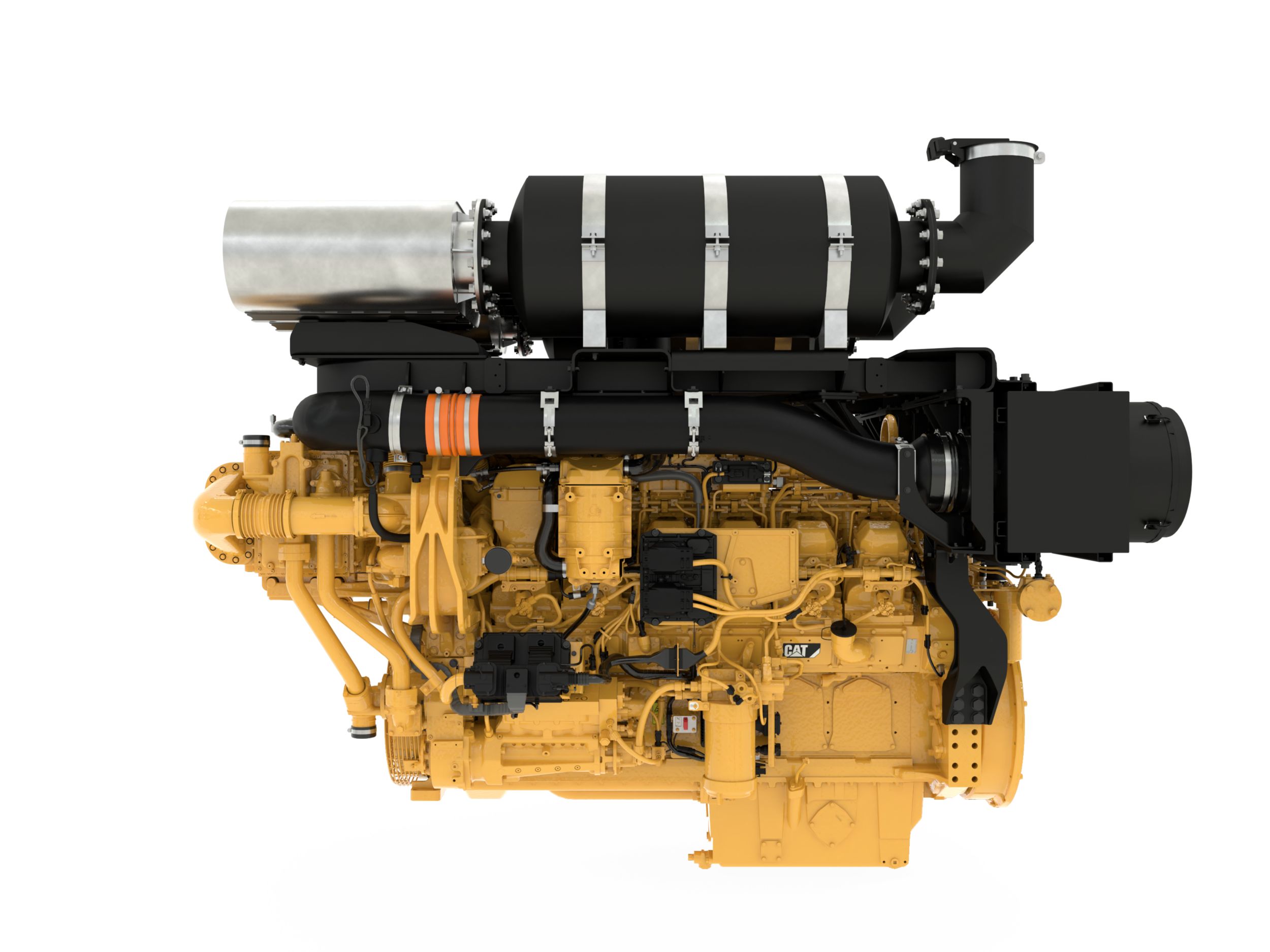

Here’s something else to think about: The newest dual-fuel well service engines on the market — specifically Cat® 3512E Tier 4 Final Dynamic Gas Blending™ engines — can achieve up to 85% diesel displacement. That means you could achieve similar savings to e-frac at a fraction of the upfront price.

2. The real cost of gas

In claiming $1 million in fuel savings a month, e-frac advocates make a big assumption: that the gas you’ll use to power your turbines is essentially free. If you’re able to use flare gas, that may be true. But is there enough available to run your entire operation or will you still need to purchase gas from another source? Do you need to condition the gas before you use it? What infrastructure is required (see #3) to get that gas to your turbines?

All of these variables take the price up considerably from “free” — which is why you need to factor them into your cost-benefit equation. Combined with the considerably higher upfront expense of e-frac, the real price of gas could extend the time it takes to recover your capital investment in gas turbines even further.

3. The need for infrastructure

A DGB™ engine like the Cat 3512E Tier 4 Final can run on diesel fuel when gas isn’t available, saving you from downtime or interruptions in operation. Lose access to gas when you’re using gas turbines, however, and your trailers don’t pump. That makes infrastructure an essential consideration if you’re thinking about switching to e-frac.

Will you need to employ CNG or LNG trailers to bring gas on site? Will equipment be required to pull in gas from a neighboring well? Will you be relying on a pipeline — which may not be constructed and ready for use until six to 12 months after your site is up and running? Again, the costs (and time) associated with gas infrastructure must be factored into the equation to calculate any real savings you may see with e-frac.

Reality vs. hype

The truth is, while e-frac does have benefits in specific applications, it’s not the be-all, end-all solution some of its proponents would have you believe. Our advice? Do your homework. Ask both your engine and gas turbine manufacturers for real-world, documented numbers — don’t settle for claims or estimates. Then compare those numbers side by side over five-, 10- and 15-year periods. That’s the best way to determine whether traditional diesel engines, DGB engines or electric fracking is the best investment for your operation.

Related Articles

-

2019-07-12 Reports From The Field: The Cat® 3512E Tier 4 Final DGB Engine

July 12, 2019

What do well service operations already using the new Cat® 3512E Tier 4 Final engine with Dynamic Gas Blending (DGB) have to say about its performance? Watch to find out.

Learn More -

2020-10-02 Tier 4 Final DGB™ Field Gas Project Is a Success

October 02, 2020

See how Cat® Dynamic Gas Blending™ engines and GTUIT mobile gas treatment delivered big fuel savings, emission reductions and safety benefits on a Texas frac site.

Learn More -

2019-10-03 Alamo Counts On Caterpillar 24/7/365

October 03, 2019

For its operations in the Permian Basin, Alamo Pressure Pumping relies on field-proven Cat engines, transmissions, power ends and fluid ends for fast, easy, trouble-free operation.

Learn More -

2020-09-10 3512E Dynamic Gas Blending Engine

September 10, 2020

No engine on the market can match the 3512E Tier 4 Final DGB Well Service engine. Industry-best diesel displacement and fuel flexibility mean you save more without giving up diesel performance.

Learn More -

2019-07-12 3 Things To Know About The Cat® 3512E Tier 4 Final DGB Engine

July 12, 2019

Dynamic Gas Blending can get complicated. This video makes it easy to understand the top features and benefits of our newest Cat® 3512E Tier 4 Final DGB engine engine for well service.

Learn More