Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

WHY EGR FOR LAND DRILLING?

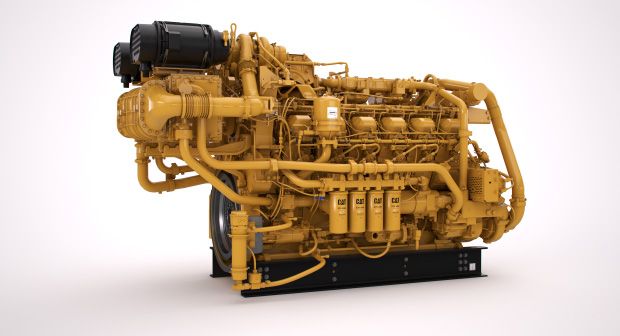

THE BETTER CHOICE FOR REMOTE, DIRTY, EXTREME ENVIRONMENTS

When you’re choosing land drilling engines to meet U.S. EPA Tier 4 Final standards, you have two options: engines with Exhaust Gas Recirculation (EGR) technology or engines with Selective Catalytic Reduction (SCR) technology. Both solutions have their strengths, but when you look at the facts, EGR emerges as the clear winner on land, while SCR is a smarter choice for marine and offshore applications. Here’s a quick look at the difference between the two systems and why each excels in a different environment.

WHAT’S THE DIFFERENCE?

In an EGR system, a portion of the exhaust gas is passed through a cooler and metered back into the engine’s intake, reducing peak combustion temperatures and oxygen levels in the cylinders. Keeping these temperatures under control helps prevent NOx from forming in the first place.

In an SCR system, Diesel Exhaust Fluid (DEF) is injected into the emissions stream, catalyzing NOx into nitrogen and water vapor. It’s an aftertreatment system that breaks down emissions after they’ve been generated.

4 REASONS EGR IS A BETTER CHOICE FOR LAND DRILLING

1. No extra space needed for storage

Space is tight on a drilling rig, and that makes accommodating DEF storage tanks and pumping units tricky. EGR technology is compact and built into the engine, with no DEF storage requirements. The footprint of a Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine is about the same as that of the Tier 2 model.

2. No shipping and stocking fluid remotely

Because land drilling typically occurs in isolated areas, keeping a rig stocked with DEF presents logistical challenges — plus extra equipment and costs for shipping it, maintaining it on site and transporting it to the next job. Since EGR technology doesn’t require DEF, that’s one less thing to worry about.

3. No special handling in extreme temperatures

Extremely hot and cold temperatures are common on land drilling sites, and DEF requires additional handling at both high and low temperatures. It degrades at 90°F and above and freezes at 12°F — a big problem during rig moves in cold weather when DEF may remain unheated for days. EGR technology isn’t affected by temperature, so it can operate in nearly any set of conditions.

4. No worries about contamination

Land drilling is dirty work. Since DEF is sensitive to contamination — and contaminated fluid can degrade the SCR catalyst — it requires closed-loop storage and delivery. That adds cost and complexity. EGR systems can function in dusty, grimy conditions with no loss of efficiency.

WHERE SCR EXCELS: OFFSHORE AND ON THE WATER

SCR is NOT an inferior technology. It’s simply better suited for marine and offshore engines, where it allows customers to switch easily between IMO II and IMO III emissions standards to reduce operating costs or to use up 5,000 ppm sulfur fuel in IMO II regions where ultra-low-sulfur diesel isn’t standard or readily available.

Related Articles

-

Cat Smart EMS

What if you could reduce runtime on your drilling rig engines up to 25 percent, cut fuel consumption up to 10 percent and increase gas consumption as well — without sacrificing power and productivity? With Smart EMS, you can.

Learn More -

EGR Fact VS. Fiction

Let’s get to the truth about land drilling engines featuring Exhaust Gas Recirculation (EGR) technology — specifically the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine.

Learn More -

EGR Fact VS. Fiction

Let’s get to the truth about land drilling engines featuring Exhaust Gas Recirculation (EGR) technology — specifically the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine.

Learn More -

EMCP 4.4

If you’re still using EIP (Electronic Instrument Panel) to monitor your rig’s engines, it’s time for an upgrade. This easy-to-use control panel, proven in the electric power industry, simplifies diagnostics and troubleshooting.

Learn More -

EMCP 4.4

If you’re still using EIP (Electronic Instrument Panel) to monitor your rig’s engines, it’s time for an upgrade. This easy-to-use control panel, proven in the electric power industry, simplifies diagnostics and troubleshooting.

Learn More -

Emissions Acronyms, Decoded

It’s not easy to remember all the acronyms associated with U.S. EPA Tier 4 Final emissions standards for land drilling rigs. Use this simple guide to keep the terminology straight.

Learn More -

Emissions Acronyms, Decoded

It’s not easy to remember all the acronyms associated with U.S. EPA Tier 4 Final emissions standards for land drilling rigs. Use this simple guide to keep the terminology straight.

Learn More -

Transitioning Onshore Drilling Rigs to EPA Tier 4 Final Engines

Use this white paper to compare the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine to the previous Tier 2 model, the 3512C, as you prepare to transition your rigs to meet emissions standards.

Learn More -

Transitioning Onshore Drilling Rigs to EPA Tier 4 Final Engines

Use this white paper to compare the Cat® 3512E Tier 4 Final Land Electric-Drive Drilling Engine to the previous Tier 2 model, the 3512C, as you prepare to transition your rigs to meet emissions standards.

Learn More -

You asked, We Delivered

Land drilling customers told us they had five big requirements for Tier 4 Final engines — here’s how the 3512E delivers on all of them.

Learn More -

You asked, We Delivered

Land drilling customers told us they had five big requirements for Tier 4 Final engines — here’s how the 3512E delivers on all of them.

Learn More