Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Author: Small Business Expert | March 28, 2023 | Topic: Used Equipment

Regular maintenance is one of the most important aspects of heavy equipment ownership. From scheduled appointments with technicians to daily operator maintenance routines, taking the time to care for your machines is key to making the most of your investment.

This guide will explain how to maintain an excavator, including a maintenance checklist and tips for maximizing your machine's productivity with Cat® dealer support.

How to Maintain an Excavator

The first place you go for information about proper maintenance should always be your excavator's Operation and Maintenance Manual (O&MM). Keep it somewhere your operators can easily access it, like within the cab.

Your O&MM will outline preventive and corrective maintenance procedures for your excavator, including model-specific part replacements and consumables like grease and engine fluids.

Excavator maintenance is both an external and an internal process. It's easy to determine your machine's condition from outward signs like scratches and dents, but paying attention to internal factors like fluid health can reveal problems that may have been undetectable.

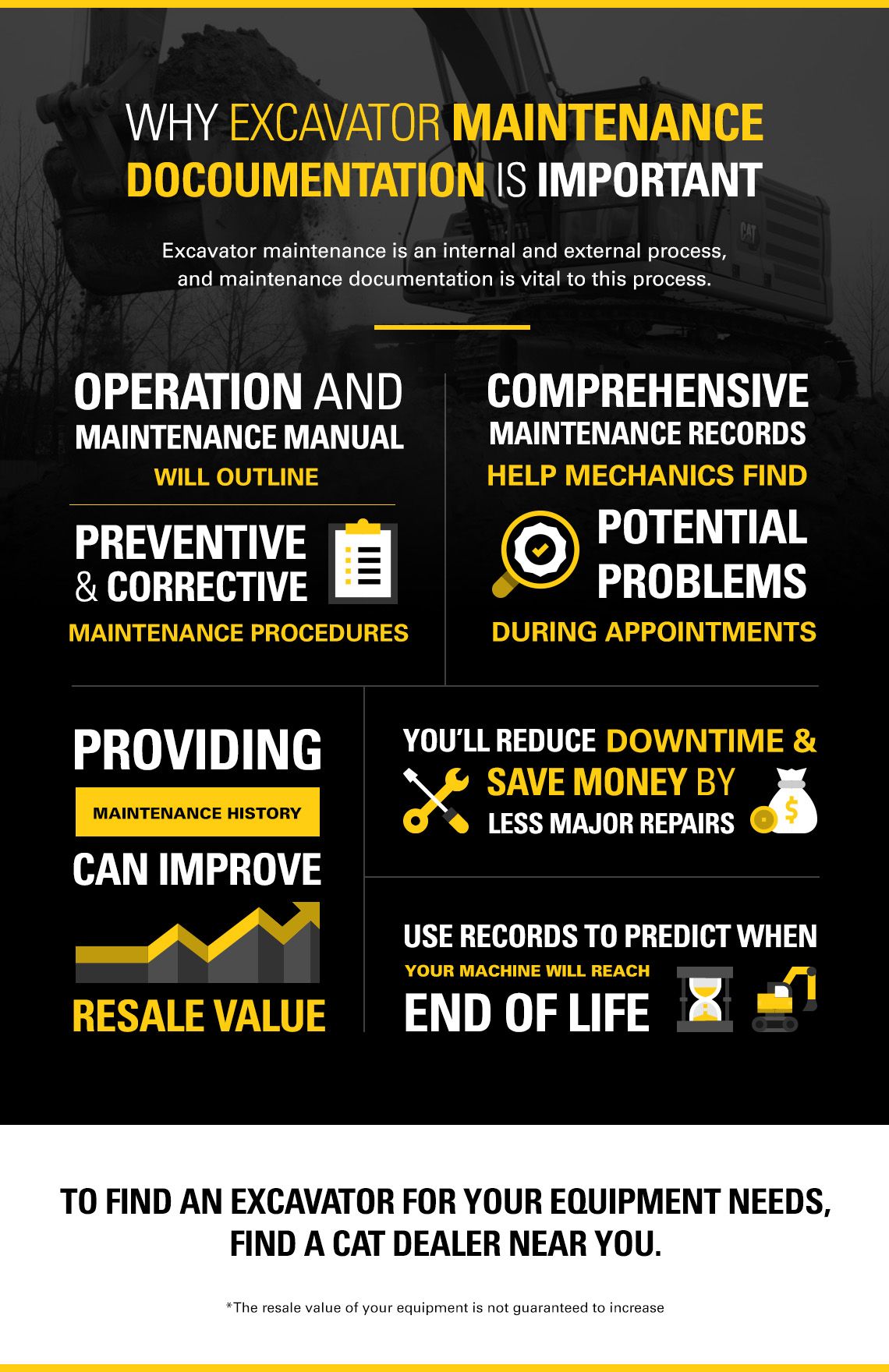

Keeping thorough, detailed records of maintenance procedures for every machine can help you effectively manage your whole fleet. Here's what makes documentation so vital:

- Comprehensive records help mechanics find potential problems during scheduled maintenance appointments and repairs.

- Providing your machine's maintenance history can improve its resale value if you choose to sell it.

- You'll reduce downtime and save money because your equipment will need to spend less time in major repairs.

- You can use these records to predict when your machine will reach the end of its life.

Using an integrated fleet management tool is an excellent way to gain visibility over all your machines at once because it stores all your information in one centralized location. Web-based fleet tracking tools like My.Cat.Com or mobile applications like the Cat App are great examples of fleet management tools.

7 Excavator Maintenance Tips

We know taking the time to perform routine excavator maintenance is essential. It increases uptime, boosts your return on investment (ROI) and extends the life of your machine. On-site preventive maintenance procedures, in addition to scheduled check-ins at the shop, are key to gaining these benefits.

Here are some of the best excavator maintenance tips for minimizing wear and keeping your equipment in good condition.

1. Start With the Right Components

Choosing the best machine for the job may seem unrelated to maintenance, but it's crucial to maximizing your equipment's useful life. Along with performing the best work, the right machine will be able to withstand the demands of your operation longer than a machine that is suited for other applications could.

Purchasing a machine with components meant for other applications can cause unnecessary damage, which can lead to lost productivity and costly repairs.

For example, mismatching the machine's shoe width to your application can significantly accelerate undercarriage wear. The appropriate shoe width for your machine will depend on the machine's size and work environment — a wide shoe is best for soft terrain, while a narrower width is better for hard ground.

This rule goes for your fluids, too. You should always use an oil that meets the specifications in your O&MM, as choosing fluids that are too viscous — or not viscous enough — can harm your excavator's systems or cause power loss to friction.

2. Create and Follow an Efficient Management Program

The ideal equipment management program should include the following elements:

- Informed purchasing: Outlining a process for purchasing heavy equipment can help ensure you're choosing suitable machines for your operation. This process may include naming your preferred vendors and creating a list of all the features and benefits you're looking for. So when you go to purchase a new excavator, you're prepared.

- Scheduled maintenance: Sticking to an excavator maintenance schedule can help you minimize downtime and keep your machine working when you need it.

- Comprehensive operator training: Investing in both in-house and dealer training for your operators is crucial to maximizing your equipment's productivity and keeping your team safe. Properly trained operators will know how best to use a machine and what to look out for when issues arise.

- Fleet monitoring: A good fleet monitoring system can help you keep track of your equipment's maintenance history, parts purchasing and use, and upcoming scheduled procedures.

3. Use Excavators Properly

Before you put any machine on your work site, you should go over the use and maintenance guidelines in your O&MM.

Your operators should also familiarize themselves with this information before they can use the machine. A thorough training course can help ensure they understand the material and know the right procedures to follow.

Here are some excavator-specific operating tips:

- Make wide turns: Turning aggressively or pivoting the machine can speed up undercarriage wear and increase your chances of de-tracking.

- Dig toward idlers: Operators should always dig in the direction of the front idlers. Digging over the final drive or back toward the sprockets can cause structural damage to the undercarriage.

- Minimize time on slopes: If your operation requires digging on hills or other sloping terrains, it's best to get your excavators off the hill as soon as possible. Additionally, ensuring the drive motor is in the correct position — facing the back of the excavator — while working on slopes will reduce track wear.

4. Monitor Fluid Health

Fluids are the lifeblood of your machine. Performing a regular fluid analysis ensures vehicle health and improves your bottom line.

Key fluids to monitor include:

- Engine oil

- Hydraulic oil

- Gear oil for final drives

- Engine coolant

- Diesel fuel

You can perform these checks yourself, or, if your dealer offers this service, you can send fluid samples in to be tested at a professional lab.

Cat S•O•SSM Services provides professional fluid analysis from expert technicians to find signs of contamination, excessive wear or other hidden issues in the fluid samples you send in. You'll also get a full report of your machine's condition and actionable recommendations to bring your equipment back to full health. Talk to your local Cat dealer for more information.

5. Change Your Filters

Check your fluid and air filters frequently and replace them according to your O&MM's recommended intervals.

Engine air filters are important for keeping your engine free of dust, which can cause damage. Check this filter frequently to keep your engine dust-free. And make sure to avoid touching the secondary engine air filter during pre-shift checks.

Lastly, make sure to regularly clean out the cab's air filter. Your operators should always have clean air to breathe, after all.

Next-Gen Cat filters can reduce filtration costs by up to 15% with proper use and maintenance. Cat excavators group these filters together to allow for easy access.

Additionally, you'll want to keep an eye on your water separators. Cat machines have a sensor inside the cab to alert the operator when drainage is necessary, so you know it's time to clean it out if the light goes on.

6. Keep an Eye on Grease

Adequate lubrication on your excavator's sliding metal parts prevents grinding and overheating due to excessive friction. Before beginning the day's work, make sure all couplers and cylinders on your machine are well-greased and apply a new coat of grease to your slewing drive bearings every few hours or according to the specifications in your O&MM. If the bearings seem loose at all, you can use thread sealant to ensure they remain tightly fastened.

Of course, you want to use the right grease for your excavator for the best results — consult your O&MM for more information.

7. Follow Startup and Shutdown Procedures

Just like how athletes warm up before an important game to ensure their best performance, giving your excavator time to warm up for the day can provide a boost to your productivity and prevent damage.

After starting the machine, allow the engine to warm up for the time specified in your O&MM — this step can take around 10-15 minutes. You can help speed up the process by engaging and disengaging the attachment controls. Then, perform the following actions:

- Turn engine speed to medium and run for five minutes, moving the joystick continuously from BUCKET DUMP to HOLD.

- Cycle the controls to allow circulation of warm oil through all cylinders and lines.

- Check the gauge, indicators and action light.

Make sure to take care in moving the machine. First, check that the area is clear, then turn the dial to the operating engine speed range. Unlock the hydraulic lockout, raise the boom and begin traveling.

Shutting the machine down requires a similar amount of care. Park the machine on a smooth, level area and reduce the engine speed. Shut the machine down accordingly:

- Lower all hydraulic implements and move lockout control to the LOCKED position.

- Allow the engine to cool down by running it at a low idle for about 5 minutes.

- Turn the key to the OFF position and remove it from the ignition.

- Wait for the "Wait to disconnect" light to turn off, then switch off the battery disconnect switch.

Once you've dismounted the machine, conduct your post-shift walkaround inspection as usual.

Daily Walkaround Inspection Checklist

Operators should conduct an excavator walkaround inspection at the beginning and end of each workday to ensure machine performance, availability and safety. Depending on your usage, it may also be a good idea to perform an inspection every 10 hours or so, just to keep everything working smoothly.

While your specific model might require a few extra steps depending on its age and the amount of work it's done, this excavator inspection checklist can help get you started.

From the Ground

First, inspect the surrounding area. Look for loose bolts, oil or coolant leaks, trash buildup or any worn parts. Once you're satisfied, move on to the machine.

Examine the boom and any attachments for damage or leaks, and make sure to apply lubricant to all cylinders and sliding parts.

Undercarriage

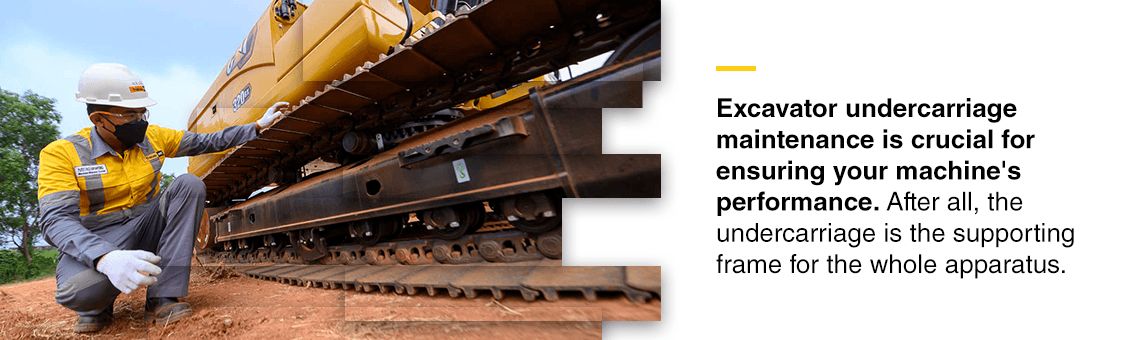

Excavator undercarriage maintenance is crucial for ensuring your machine's performance. After all, the undercarriage is the supporting frame for the whole apparatus. The key areas to check on your undercarriage are:

- Joints and pins: Look out for pin walking and pitch extension, and make sure shoes look lubricated.

- Track hardware: Make sure that nothing is loose or missing from your tracks.

- Idler: Check for signs of abnormal wear or leaks.

- Carrier rollers: Make sure rollers are clean and free of any debris. It's a good idea to clean out any dirt and debris that could lead to buildup at the end of the workday — you can use a pressure washer to get any hard-to-reach grime. Additionally, be on the lookout for signs of damage.

- Sprockets: Look for missing hardware or signs of damage like bending, breaking or cracking.

- Track tension: In your excavator track maintenance check, make sure this component sags slightly between rollers. Excessive sagging or tautness between rollers can accelerate wear on your pins, bushings and sprockets.

Engine Compartment and Platforms

Examine all hoses and belts for cracks and signs of wear or damage. Then, open the engine compartment and check the fluid levels of the following:

- Engine oil

- Swing gear oil

- Fuel tank

- Diesel exhaust fluid (DEF), if applicable

Lastly, make sure the engine compartment is clean and free of trash or other debris before closing it back up.

Inside the Cab

Before you turn on the engine, make sure the seat, seat belt and mounting are in good condition. Adjust the seat and mirrors accordingly. Additionally, check the installation date on the seat belt if it's been some time since it was last replaced.

Make sure the following are functioning properly:

- Indicators

- Horn, lights and travel alarm

- Monitor panel

- Switches

- Travel controls

- Heating and cooling systems

If you want to add your inspection results to a fleet management tool, the Cat Inspect App allows you to quickly and easily track equipment inspections across your whole fleet right from your mobile device. It's also integrated with the Cat App, My.Cat.Com and VisionLink, which allows for high visibility and convenient tracking.

Cat® Maintenance and Extended Protection Plans for Your Excavator

Our dealers and technicians are experts in Cat excavator maintenance and repair, so you can count on your dealer to provide the right support for your machine for as long as you own it.

Some Cat dealers also offer Customer Value Agreements (CVAs). A CVA is a hassle-free ownership plan designed with your convenience in mind. The specific details of a CVA vary from dealer to dealer, but all provide the following benefits:

- Genuine Cat parts delivered to you in time for your scheduled maintenance

- The security of expert dealer support and service

- Peace of mind from easy equipment health management

Additionally, many Cat dealers offer Equipment Protection Plans (EPPs) for new, used and rebuilt machines. An EPP provides coverage beyond the standard machine protection plan and protects you against unplanned repair costs from covered problems. Depending on your circumstances, multiple coverage options are available to fit your specific needs and budget.

Consult with your local Cat dealer for more information on CVAs and EPPs. They can explain what options are available to you and how you can get started.

Consult Your Local Cat Dealer Today

If you want to boost your organization's productivity and extend your excavator's life, your local Cat dealer can help. Our dealers are trusted experts in the heavy equipment field — no one knows more about getting the most from a piece of Cat equipment.

Check out our online selection of used excavators to see what our dealers currently have in stock, or find a Cat dealer near you. If you have a specific model or hour range in mind, we can let you know when something matching your needs becomes available near you.