Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Author: Small Business Expert | May 25, 2021 | Topic: Used Equipment

Running a forestry business is a challenging and rewarding endeavor. Forestry business owners need to secure continual access to lucrative woodlots, and they also need to invest in heavy timber equipment that cuts back on labor costs and maximizes productivity.

This guide to forestry equipment introduces the top equipment and attachments that forestry businesses can invest in for success. We discuss the different applications of each machine and its attachments, and provide tips for choosing forestry equipment for your business. We also compare the pros and cons of buying new vs. used forestry equipment, and why choosing Cat® Certified Used forestry equipment ensures you get the best value for your investment.

5 Best Types of Equipment for Forestry Jobs

The forestry industry thrives on dynamic and streamlined work. Each critical step in the timber harvesting process needs to be highly efficient, using the top machines that optimize output. Forestry operations rely on a variety of heavy equipment to complete essential tasks. From felling to extracting to loading to transporting, forestry workers depend on specialized machines that get more done in less time. Additional machines are required to prep logging sites by building and maintaining service roads that give easy access to loggers and their equipment.

With so many specialized machines providing unique services, there are several considerations to decide which machines are the best equipment for forestry. An equipment list for a forestry business can provide a helpful overview of the best machines for the job. Below are the common types of heavy equipment for forestry and which applications they’re best suited for:

1. Dozers

Long before logging crews can enter a woodlot to begin processing trees, crews need to build access roads. A dozer is the go-to machine for this task, as it’s capable of effortlessly carving a path through a forest. With sheer brute strength, dozers move at a slow speed and plow the earth, trees, boulders and everything else to create a clear path in the dozer’s wake.

Often, dozers are used during and after forest fires to create a fire break. Fire breaks are long lines cut into the forest to disrupt the path of the wildfire so it cannot continue burning in that direction. Dozers come equipped with tracks instead of tires, which gives them more traction with the ground and enables them to work on steeper grades. In addition to creating roads, dozers are also excellent at leveling ground with their large, heavy blade.

2. Excavators

The excavator is an extremely versatile machine featuring a large arm that can be equipped with a wide range of attachments. Most commonly, a bucket attachment with an opposable thumb is equipped to give the excavator the ability to dig holes and trenches and move heavy objects around like trees, boulders and other equipment.

In forestry, excavators are frequently used to dig out tree stumps after a tree has been cut down. The bucket attachment allows the excavator to make precision digging movements, which are ideal for digging around stumps and unearthing them to be transported away. Usually, excavators come equipped with a blade that can be lowered and used to push earth. This blade gives the excavator the capability to level soil and create pathways free of debris.

3. Forest Machines

Forest machines are designed specifically to meet the demands of tree processing in the field. Similar to an excavator in their design and operation, forest machines can come equipped with a few different attachments to perform common tasks required during a tree harvesting operation. These attachments include felling heads, harvest heads and grapples:

- Felling heads: Felling heads are designed to grip a tree and cut it at a low level. After the sawing is complete, the forest machine can reorient the tree horizontally and stack it to the side.

- Harvest heads: Harvest heads specialize in cleaning the fallen trees of branches and stems. They accomplish this by feeding the tree through the attachment with feed rollers as delimbing knives remove any branches that cross their path.

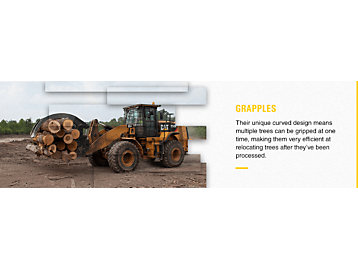

- Grapples: Grapples are attachments specifically designed to grab bunches of trees that have been delimbed. They have a distinct advantage over using a generic excavator bucket and thumb attachment because of their curved design that can cradle many trees at once.

4. Motor Graders

The grader is a large piece of heavy equipment used to create smooth, flat road surfaces. Equipped with a large blade, the grader runs along the road surface and breaks down larger chunks of rock and debris while using those pieces of debris to fill shallow holes. The result is a flatter and smoother road, free of potholes, uneven slopes and other debris.

Motor graders are frequently used on established forest service roads to reestablish the smooth surface that existed when the road was first constructed. Over time, logging trucks and other traffic begin to create imperfections in the road, such as potholes, cracks and other obstacles, giving the road a washboard surface and making it almost undrivable.

Depending on the frequency of road traffic, a motor grader might be required to service a forest road multiple times a month to keep it smooth and ideal for logging truck traffic.

5. Skidders

Skidders are an essential piece of equipment used to transport a large number of trees to another location where they can be loaded onto a logging truck. After the forest machines cut down and delimb trees, the raw timber is stacked in a pile to be transported by a logging truck to a sawmill or other type of lumber processing facility. The skidder comes equipped with a heavy-duty grapple attachment designed to grab a large number of processed trees at one end and drag them to their next destination, usually an area more suitable for loading a logging truck.

The skidder grabs the trees on one side and lifts them off the ground. It gets its name “skidder” because the opposite ends of the trees skid along the ground as they’re being transported. Depending on the distance between the processing area for the trees and where they are loaded onto the logging truck for transportation, a skidder might be an excellent time- and money-saving option for your forestry operations.

5 Best Forestry Equipment Attachments

Another crucial consideration is which types of work tools you’ll need. With the right work tools, you can take any standard heavy equipment and turn it into a highly functional and versatile machine that takes on specific duties. Here are five of the best equipment attachments for forestry businesses to invest in:

1. Felling Head Attachments

Felling head attachments are often the first piece of machinery to make contact with the trees. They are attached to a forest machine and work by gripping the tree in their grapple arms. Once the tree is secured, a bar saw is activated on the felling head. The bar saw is located closer to the ground to ensure trees are cut off at their lowest possible level. After the bar saw completes its cut, the felling head tips the tree over horizontally, where it can be delimbed using a delimber attachment.

2. Delimbers

Delimbers are essential tools in the forestry equipment lineup. First, delimbers are attached to forest machines, which are essentially excavators with modifications that make them more suitable for forest operations. The delimbers work by gripping a tree in their arms and then activating the feed rollers.

Feed rollers are mechanical wheels with teeth that dig into the tree to give it a good amount of grip. As the feed rollers push the trees through, delimbing knives are used to cut off branches. Delimbing knives are typically stationary blades, but they can also be chainsaw-like attachments. Once the tree is delimbed, it shoots out the other side of the delimber where it can then be stacked for further transportation.

3. Forestry Mulchers

After trees have been harvested, their stumps may still remain. These can essentially make the land unusable. Luckily, forestry mulcher attachments are designed to tackle the problem of leftover tree stumps.

Forestry mulchers attach to forest machines and excavators and work by rotating a shaft containing many hardened steel teeth. With a combination of downward force from the forestry machine and the rotation of the mulcher shaft, the teeth are able to pulverize the remaining stump. Forestry mulchers are so effective at destroying stumps that they can often remove the stump below the ground level. Afterward, the stump hole can be filled with dirt and smoothed over, leaving no trace of the stump.

4. Grapples

Grapples are attachments designed to fit on forestry machines and make quick work of transporting trees. Their unique curved design means multiple trees can be gripped at one time, making them very efficient at relocating trees after they’ve been processed. Additionally, grapple attachments are used to load and unload logging trucks before and after their journey, making them useful in the forest and at the lumber’s end destination.

5. Buckets

As one of the most versatile attachments in heavy equipment, bucket attachments are necessary for site clearing and cleanup. Use a bucket attachment throughout operations to clean up debris and clear access ways. You can use an excavator bucket to dig around tree stumps to extract them for removal. Or, put the bucket attachment to use in a final cleanup pass, loading and hauling away unwanted brush or trees.

There is an extensive range of buckets available to attach to your heavy equipment, whether it’s an excavator or a loader. General purpose, severe duty and excavator buckets with thumbs all help you to clean up with precision and efficiency.

Should I Buy New or Used Forestry Equipment?

Besides which type of equipment and attachments to invest in, forestry businesses need to consider whether to buy new or used machines and work tools. A machine is a business asset, so it’s critical to keep in mind your best option for return on investment (ROI). Some businesses invest in new equipment to maximize the full product life cycle. For other businesses, used equipment may be the best choice.

Here are some reasons to consider buying used forestry equipment for your business:

- Reduce your upfront costs: Used equipment comes with a lower sticker price and a slower depreciation rate. Pre-owned assets are also more cost-effective to insure than new ones.

- Increase your business flexibility: If you’re looking to take on seasonal or short-term work, investing in used equipment is a convenient way to meet immediate project needs. Once the seasonal contract is finished, you can resell the equipment.

- Expand your fleet: For growing businesses, cash flow is essential as it allows you to adapt and expand in response to the market. Reduced purchase costs mean you can invest in more equipment at once and expand your fleet.

- Get access to a wider inventory: The pre-owned equipment market is massive, meaning you’re likely to find the exact model of machine you’re looking for. With a wide inventory to choose from, you’ll also have a greater chance of getting the best deal possible.

Small businesses looking to invest in pre-owned forestry equipment need to source their machines and attachments from a reliable dealer. Before buying used forestry equipment, be sure to ask about the service and maintenance history of the machine to ensure it’s a wise investment that will last.

Why Buy Forestry Equipment From Cat Used?

When buying pre-owned equipment, small business owners want guaranteed performance. To ensure you make a reliable investment in used equipment, choose Cat Certified Used for the highest standards in pre-owned heavy equipment. Here are some of the benefits of choosing Cat Certified Used forestry equipment:

- Transparent service records: Most Cat Certified Used equipment is sourced from reliable local dealers' rental fleets. This equipment comes with a complete service history demonstrating high maintenance standards throughout its service life.

- Maintained with genuine Cat parts: Conducting parts replacements using genuine Cat parts is one of the reasons Cat Certified Used equipment is so reliable. Everything is done in-house, meeting the high manufacturing and servicing standards Caterpillar is known for.

- Extensive Cat Used inventory: When shopping for pre-owned equipment, small businesses benefit from the Cat Dealer Network — hundreds of Cat locations around the world all operating by the same standards. Get access to an extensive selection of used equipment sourced from regional dealers when you need it.

- Backed by the Caterpillar warranty: Called an Equipment Protection Plan, or EPP, this comprehensive coverage protects more than 70 different powertrain and hydraulic components.

Choose Cat® Certified Used Forestry Equipment

This forestry equipment guide highlights the wide range of heavy equipment and attachments needed to operate a successful forestry business. Choosing the best equipment for forestry jobs means investing in machines that deliver versatility, reliability and high performance. By investing in used Cat forestry equipment that’s been maintained to the highest standards, businesses can save money and remain profitable.

Browse our dealers' inventory of Cat Certified Used forestry equipment. Sign up to receive email alerts and get notified when the equipment you’re looking for becomes available near you. Or get in touch with your local Cat dealer for help sourcing the pre-owned equipment you need.