Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Advansys™ GET

Advansys 70-230 tips and adapters are built specifically for demanding high production applications, shift after shift.

The highest standard in hammerless GET

Optimize the performance of your 924-994 wheel loader or 311-390 hydraulic excavator with Cat Advansys GET. This hammerless Cat system simplifies installation with integrated retention components and streamlines retrofitting with adapters that drop into the same space as K series.

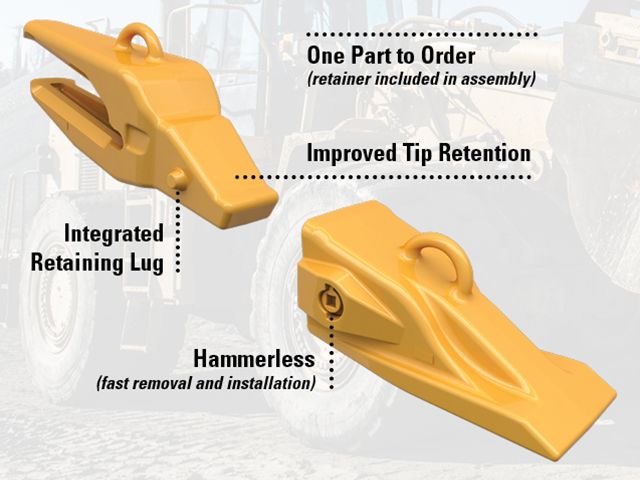

Cat® AdvansysTM Features and Benefits

Designed for the toughest jobs

- Exclusive performance features such as tapered tip sides offer less drag and higher productivity.

- New and optimized tip shapes put wear material where you need it most.

System Reliability

- Stronger adapter noses for 50% stress reduction.

- Improved adapter nose geometry extends adapter life.

Installation and Removal:

- Retainer lock requires no special tools for quickest hammerless tip removal and installation.

GET Management

The most important part of any machine is its work tool.

Protect expensive machine components, reduce operating costs, and get the most out of your machine’s performance. Proper selection of GET has a direct effect on the productivity, fuel consumption, and maintenance costs of your machine. Your Cat dealer can help you establish an effective management program that minimizes preventable problems.

Bucket Edges, Tips, and Adapters

Check for:

- Cracks on base edges beside adapters and corner welds

- Cracks on base edges on top and bottom of rear weld

- Excessive wear on the bucket tips. Tips worn through on the bottom or cracked in the pocket area should be replaced.

- Damage to the bucket tip adapters. Badly worn bottom straps that are worn into bottom cavity should be replaced.

- Damaged or missing retainer pins. Tap lightly on each pin. If pin moves easily, replace the retainer.

From the Field

Here's what customers are saying about Cat Advansys GET:

North America

South America

Europe, Africa, Middle East

Asia Pacific

SIMPLER, LESS FREQUENT INSTALLATION FOR BETTER EFFICIENCY AND LONGER LIFE

From the field…

“It’s simple, efficient, more effective. I think one of the greatest aspects of the Advansys system is that we can put the machine back to work as quickly as possible.”

Jesse Wenzel, heavy equipment welder, Superior Ready Mix