Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Asset Intelligence Detects a Fouled RO Membrane

What Happened?

Cat Asset Intelligence uses advanced analytics to qualify raw data into actionable information. Hundreds of thousands of raw data values for each asset are evaluated against a tailored set of rules and intelligently converted into much smaller representative sets of data. Algorithms then determine whether the criteria is met for a fault condition to exist, all without a human in the loop. A Cat Asset Intelligence Fleet Advisor was notified by the system of a fouled reverse osmosis (RO) membrane through carefully constructed faults.

What Was the Underlying Cause?

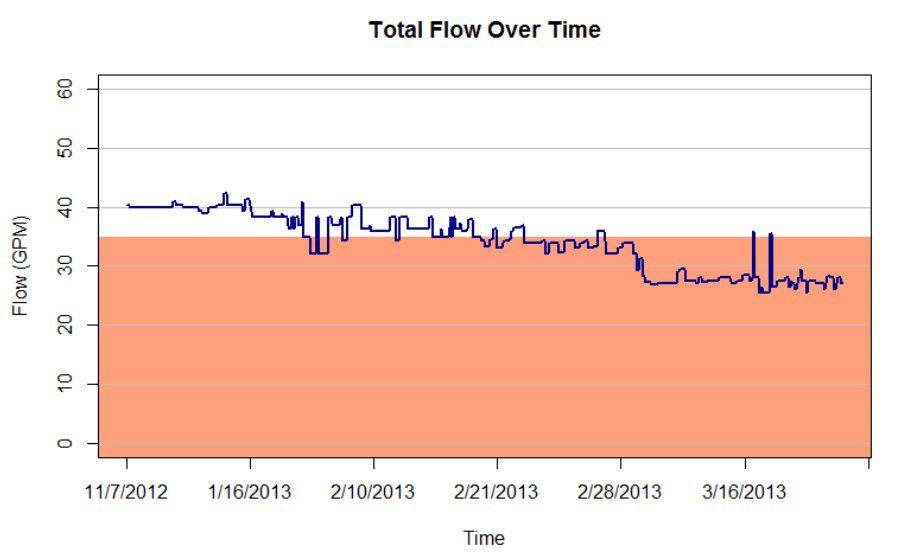

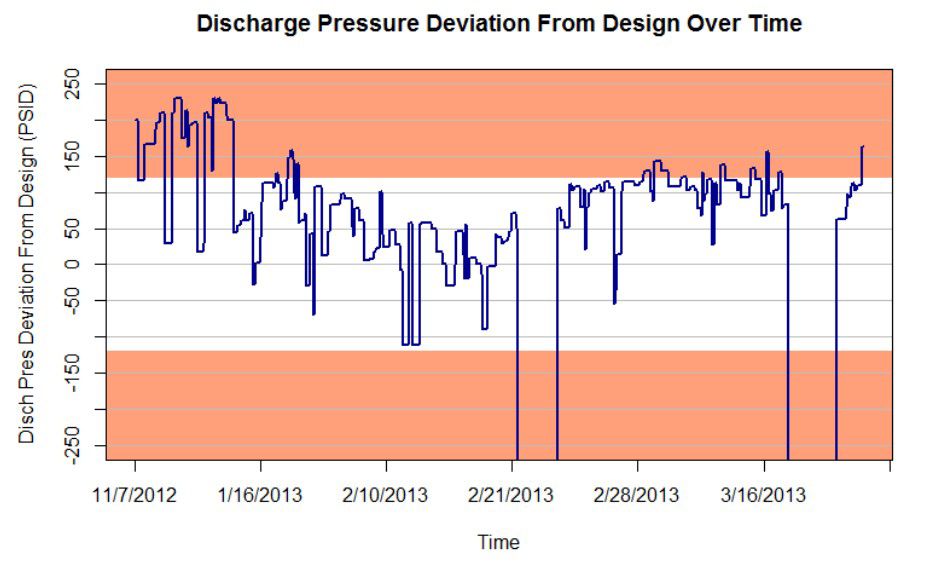

The RO membrane is a component in the RO units that is responsible for producing fresh water from salt water. It involves pretreatment to the incoming seawater to remove impurities, pumping the water into high pressure, and then sending highly pressurized seawater through the RO vessels past RO membranes that will allow only the freshwater to pass through. When RO membranes are fouled, less freshwater is able to pass through; thus, more work (and more cost) is required to produce the same amount of freshwater for a fouled RO membrane compared to a properly functioning RO membrane. A low flow rate water through the RO unit and high discharge pressure are strong indicators of a fouled RO membrane. The flow rate fault was alarming since the flow rate was under acceptable limits. The discharge pressure fault was not in an alarming stage, which may have caused a fleet advisor to overlook the fouled RO membrane, except intelligently developed logic verified the discharge pressure was greater than the design discharge pressure for the current water flow. Therefore, the fault was alarming, bringing attention to the fouled RO membrane.

What Was the Value to the Customer?

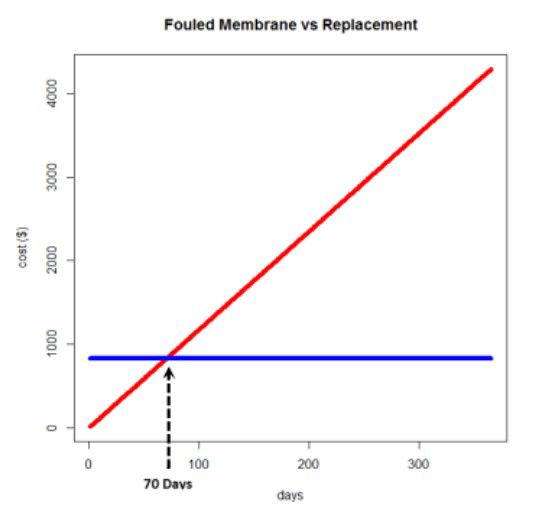

A fouled membrane causes the RO unit to work harder to produce freshwater using more fuel and thus more money. At $185.00 per barrel of fuel, running an RO units with a fouled membrane would cost an additional $4292.40 per year. Instead of running an RO unit with a fouled membrane, the membrane can be replaced for just $826.50. The new membrane would pay for itself in saved fuel in just 70 days.