Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Fleet Advisor Predicts Preventable Failure of Third-Party Component

What happened?

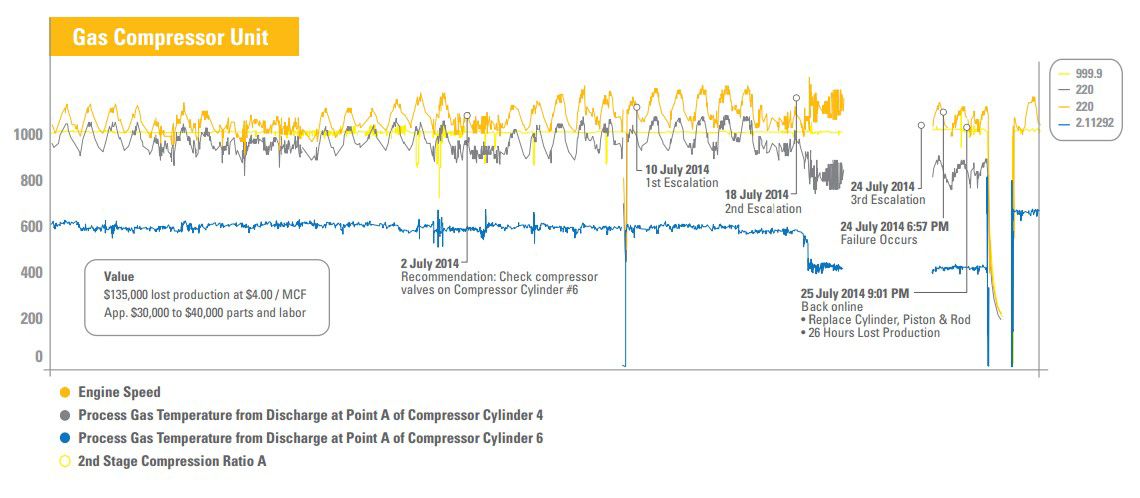

Condition Monitoring data indicated that the discharge temperature for one cylinder in the gas compressor was increasing. The Fleet Advisor used visualization tools to evaluate the data, identify the root cause of the problem and develop a recommendation for the customer. On July 2, 2014, the Fleet Advisor contacted the customer, suggesting that the compression valves be inspected and replaced if found to be defective. The advice was not followed. The Fleet Advisor contacted the customer two more times—on July 10 and 18—with the same recommendation. On July 24, a compressor valve failed and damaged the cylinder. The unit was down for 26 hours while a replacement cylinder was procured and installed.

What was the underlying cause?

The valve failure was attributed to a random reliability issue. If the customer had more confidence in the value of the data and followed the Fleet Advisor’s recommendation, both the valve and cylinder failures could have been prevented.

What was the value to the customer?

Choosing not to follow the Fleet Advisor’s first recommendation—made more than three weeks before failure—was a costly mistake. If the valves had been inspected and replaced during normally scheduled maintenance, the cost of the repair would have been less than $2,000. By waiting until failure, the customer incurred repair and downtime costs of approximately $165,000. The customer now appreciates the value of Caterpillar’s remote monitoring capabilities and Fleet Advisor expertise.