Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cooling Issue Detected and Resolved Before Failure

What happened?

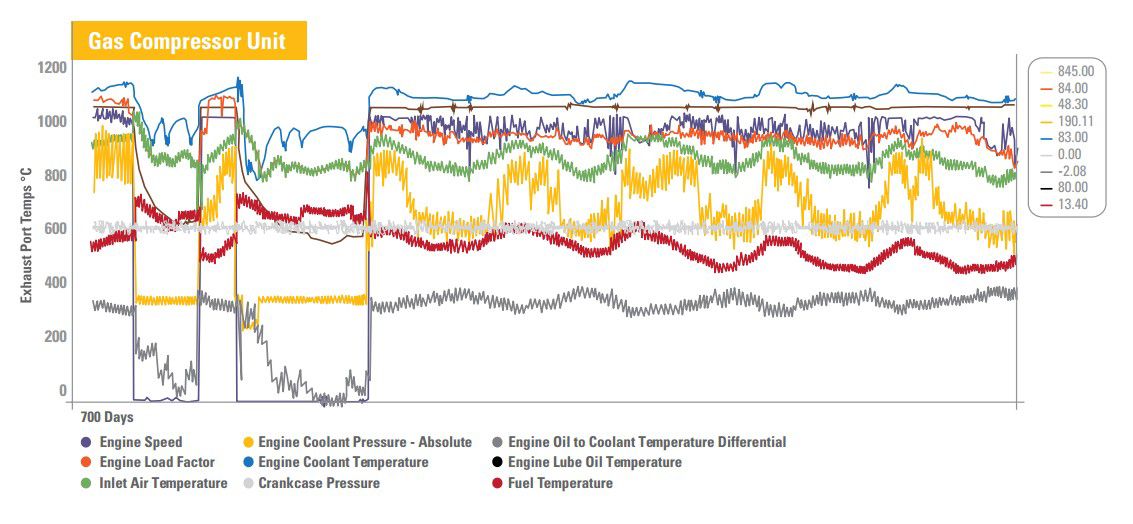

A Cat® Fleet Advisor monitoring a gas compressor package noted that the system was overheating. A review of the data indicated that:

- The Intake Manifold Air Temperature (IMAT) was high during hotter parts of the day

- The engine jacket water temperature was floating with ambient temperature, rather than remaining steady as an outlet-controlled system should have been behaving

- Varying cooling pressures at the thermostat confirmed it was operating effectively

This combination of conditions led the Fleet Advisor to suspect a problem with the Air Cooled Heat Exchanger (ACHE). The customer was notified about the issue and confirmed that the ACHE had been marginally sized.

What was the underlying cause?

The combination of a marginally sized ACHE and high ambient temperatures was causing excessive coolant temperatures.

What was the value to the customer?

With knowledge of the situation, the customer was able to prevent an unplanned outage by reducing engine load during the work cycle and adding cooling capacity during a normal maintenance window. Taking these corrective actions allowed the customer to prevent accelerated engine wear and avoid unplanned downtime, which would have cost an estimated $2,200 per hour.