Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Early Detection of Injector Problem Prevents Unscheduled Downtime

What happened?

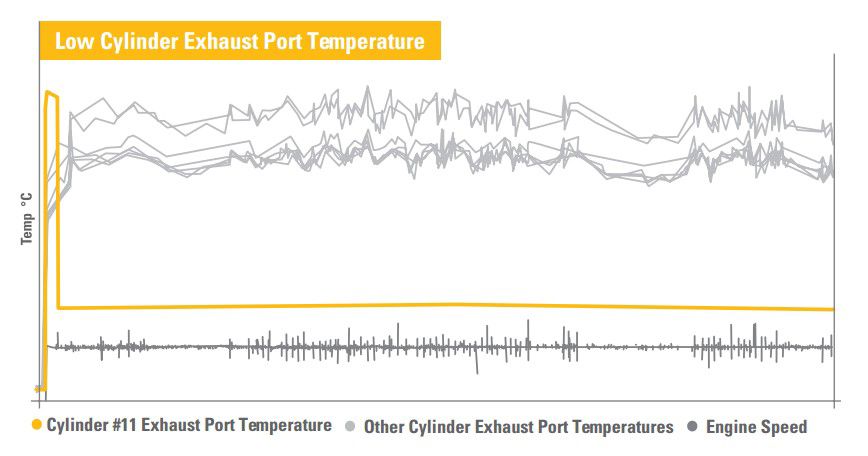

A Cat® 3516C engine in an offshore oil rig application is enrolled in Advanced Condition Monitoring, part of Cat Connect Services. The Fleet Advisor responsible for monitoring the engine noted that exhaust temperatures in cylinder #11 had dropped as low as 260° C, while temperatures in the other cylinders were running in the 380° C range. He also identified a 40° C temperature difference between cylinder banks. The Advisor recommended performing a cylinder cutout test to determine whether the problem was electrical (thermocouple/harness) or mechanical (injector/ cylinder). The test confirmed a mechanical issue with cylinder #11.

What action was taken?

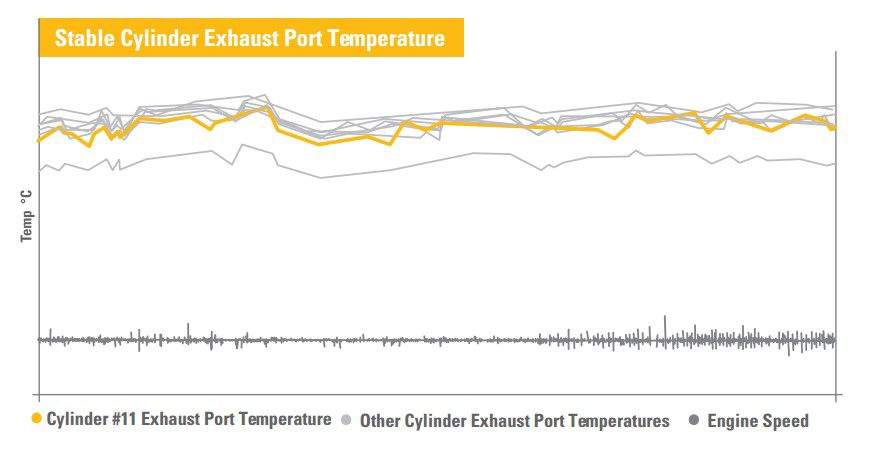

After reviewing the cutout test results, the Cat Advisor suggested swapping the cylinder #11 injector with any of the even-bank cylinders to expose the weak or failed injector. The faulty injector was identified and replaced; a post-test confirmed that all cylinders were operating normally.

What was the value to the customer?

By taking immediate action to correct the problem before a complete cylinder failure occurred, the customer was able to avoid catastrophic repair costs and prevent an unplanned outage, saving millions in production losses.