Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Fleet Advisor Detects Improper Maintenance Procedures

What happened?

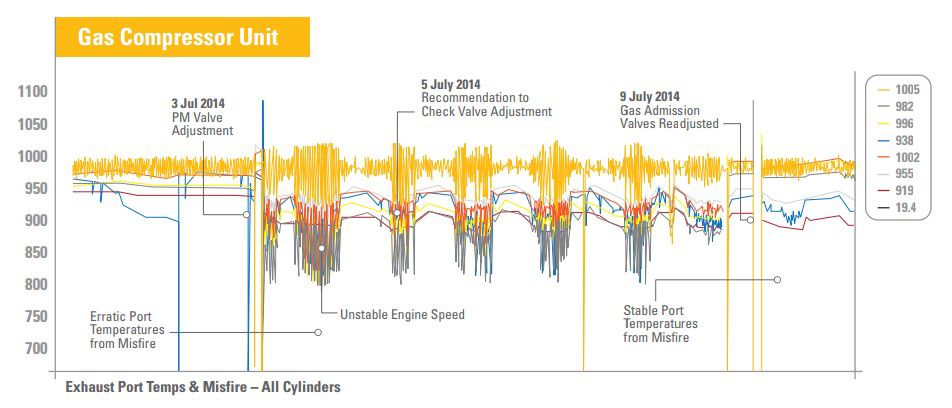

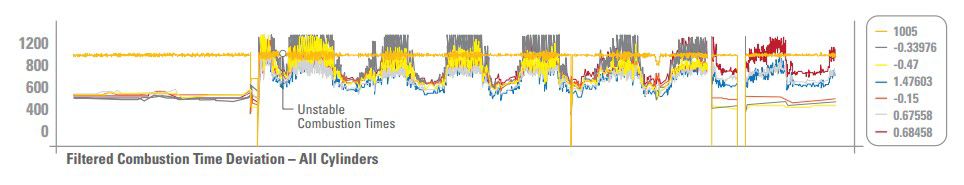

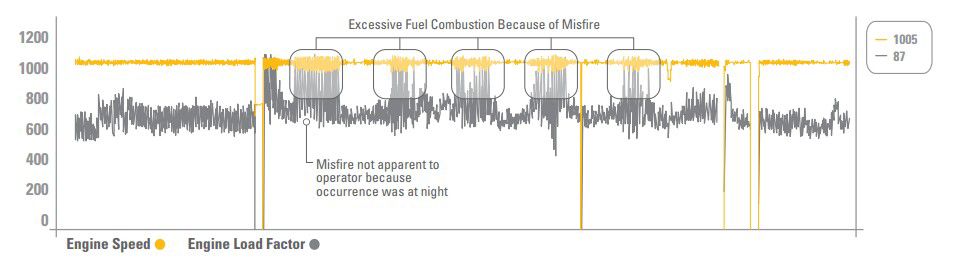

A Caterpillar Oil and Gas Fleet Advisor discovered data indicating that one engine bank was misfiring and exhibiting erratic port temperatures and excessive fuel consumption. The situation was happening at night when the engine had been put back into service following scheduled maintenance. The Fleet Advisor used visualization tools and his knowledge of the engine and application to theorize that maintenance was being performed by two technicians, only one of whom was adjusting the valves correctly. The Advisor notified the dealer and customer, recommending that all valve lash settings be inspected and readjusted as needed. An inspection was performed; adjustments were made; the training need was identified, and failure was averted.

What was the underlying cause?

Two technicians were making valve lash adjustments during routine maintenance, one on each engine bank. One technician was performing the procedure correctly; the other was not.

What was the value to the customer?

By taking immediate action to correct the problem, the customer saved as much as $20,000 in lost production and callout expenses for detonation and/or over-torque shutdowns. In addition, an important training need was identified and addressed.