Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Valve Misfire Detected and Corrected Without Expensive Repair

What happened?

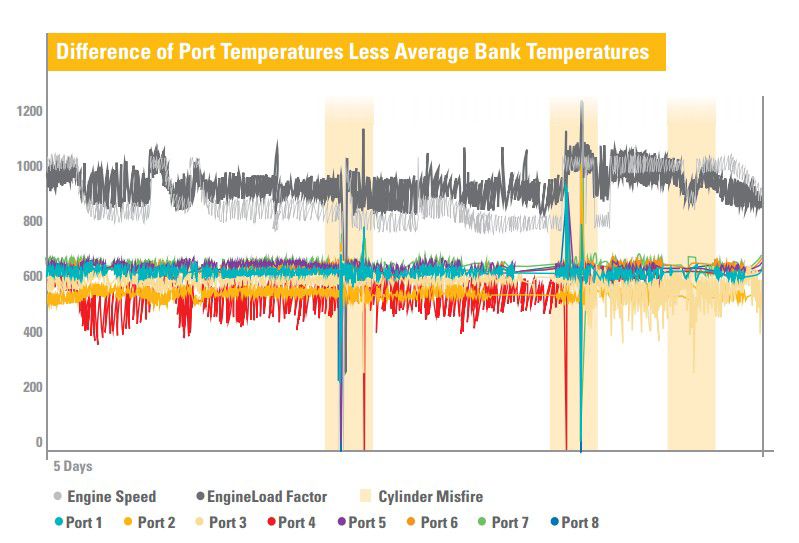

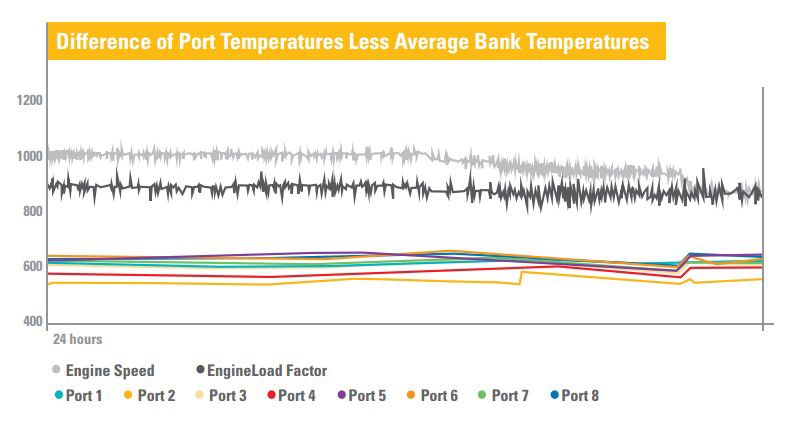

An unmanned natural gas compressor station based in the United States is equipped with four compressor packages and monitored remotely with Cat® Equipment Care Advisor (ECA). ECA analytics detected a misfire on two cylinders of a G3608 engine. At the time the misfire was discovered, it wasn’t impairing performance or causing engine damage.

What action was taken?

The Fleet Advisor recommended that the pre-chamber needle valve be temporarily adjusted, then returned to its normal position if minor clogging occurred in the valve. This procedure stopped the misfire. What is the value to the customer? The customer benefited in several ways:

- No unnecessary parts replacement. The issue was corrected without replacing the parts (spark plugs and check valves). As a result, the customer didn’t lose the value remaining in the existing parts and didn’t have to spend approximately $1,250 for replacement parts and the labor to install them.

- No lost revenue from an unnecessary shutdown. Because the situation was resolved without an inspection or repair, production wasn’t interrupted unnecessarily.

- No unscheduled downtime. The proactive valve adjustment reduced the risk of a future failure that could have resulted in an unscheduled outage and lost production estimated at $1,500.

The total value derived from this single issue is approximately $2,750. The cost of the service is $400 per month at 98% run time.