Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

TRUCK LOADING OPERATOR TIPS

When it comes to maximizing fuel efficiency for your Cat® wheel loader, every movement counts.

The best operators make sure every turn of the wheel loader is deliberate and calculated when loading trucks. Your angle of approach is key when both digging into the face of the material you’re working on and unloading the material into a truck. And even small movements can add up, leading to slower cycle times and wasted fuel.

Here are a few operator tips for how to best load a truck.

Basic operator tips for loading trucks

- Make sure you’re loaded and in position when the truck approaches. Work the face the width of two buckets to prevent digging a slot in the face. Always make sure your loader is straight, not articulated, when you dig into the face; this puts less stress on the machine.

- Stay in first gear while you’re loading, which gives you the best balance between ground speed and hydraulic speed. If you feel like you need to use second gear, you may be too far away from the face or the truck.

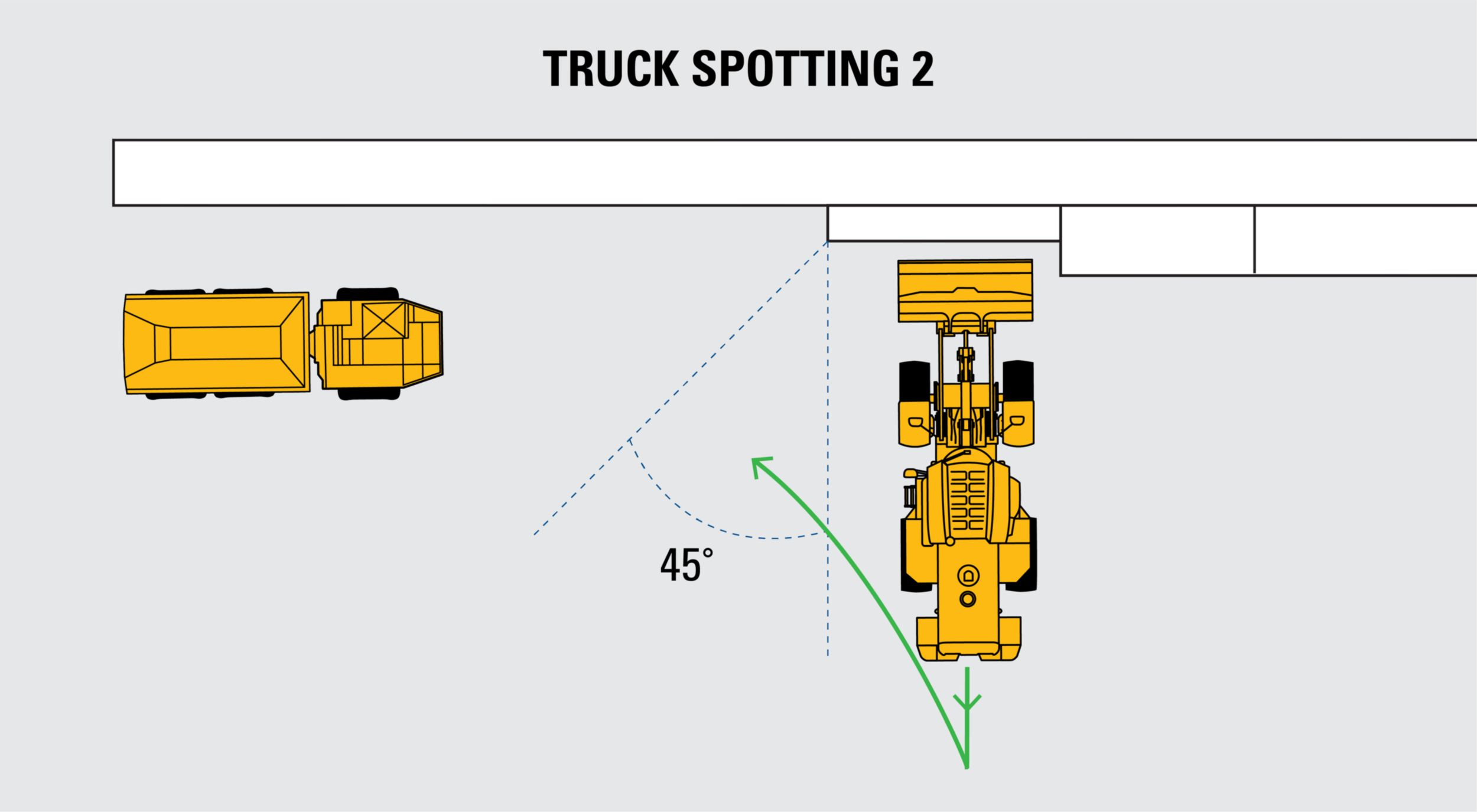

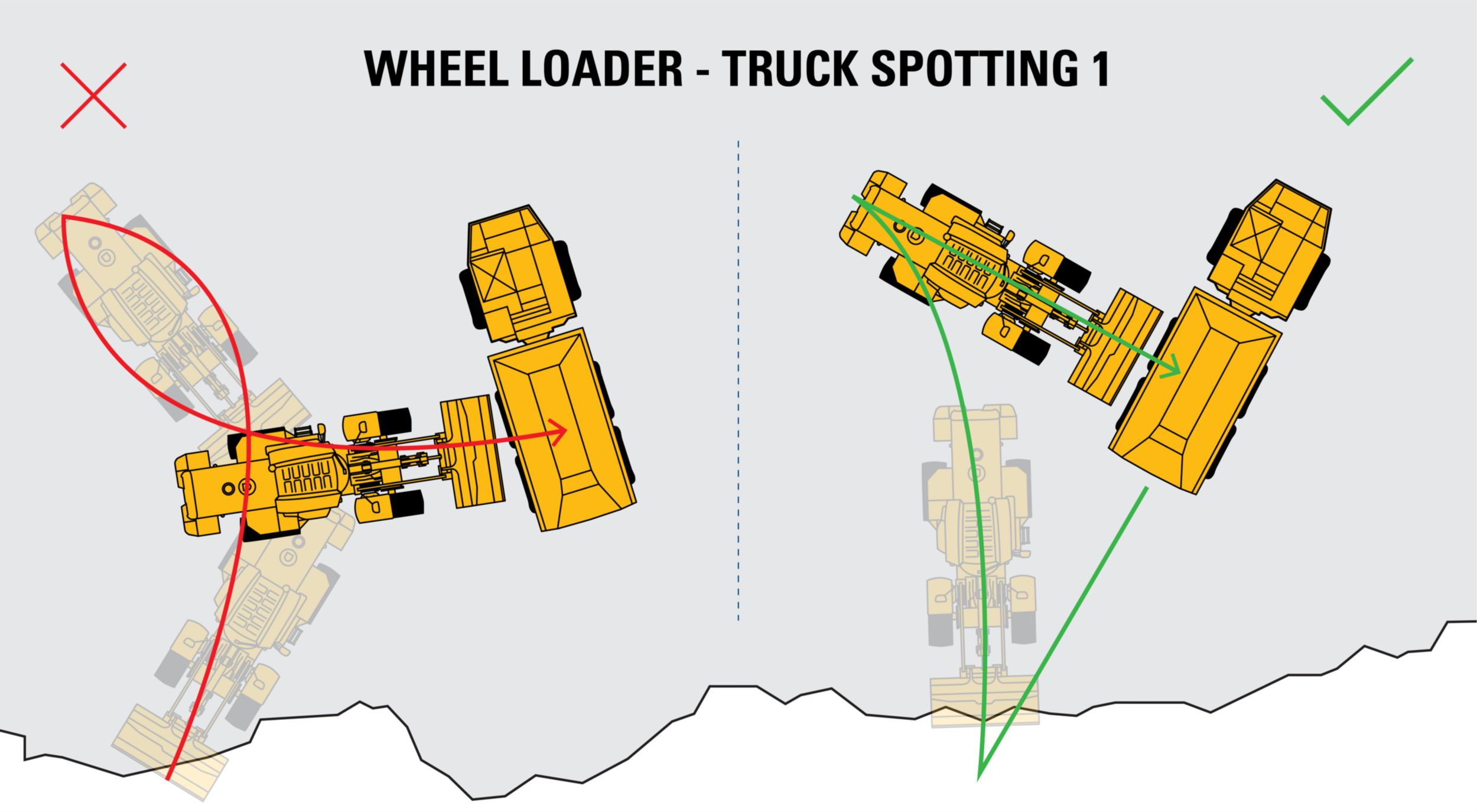

- Work left to right to create a pocket for the trucks to back up to you at a 45-degree angle. Why 45 degrees? If you have to make 180-degree turns every pass to move your loader perpendicular to the truck, you’ll slow your cycle times and waste a lot of fuel. You should be in a position that allows you to make a tight V-pattern between the material, your pivot and the truck. Your tires should rotate no more than 1 to 1½ times in both directions, but the shorter the rotations, the better.

- When you approach the truck, don't quite complete the turn. Leave your loader slightly articulated, about 5 degrees. That way, when you drop into reverse, you'll already be in your turn. This brings your pivot point closer to the face and can shave as much as a second off each cycle.

- Center the material in the truck body as you load. If you're working with large rocks, try to start with at least one bucket of smaller material on the first pass. That will cushion the larger rocks to come.

Parallel digs

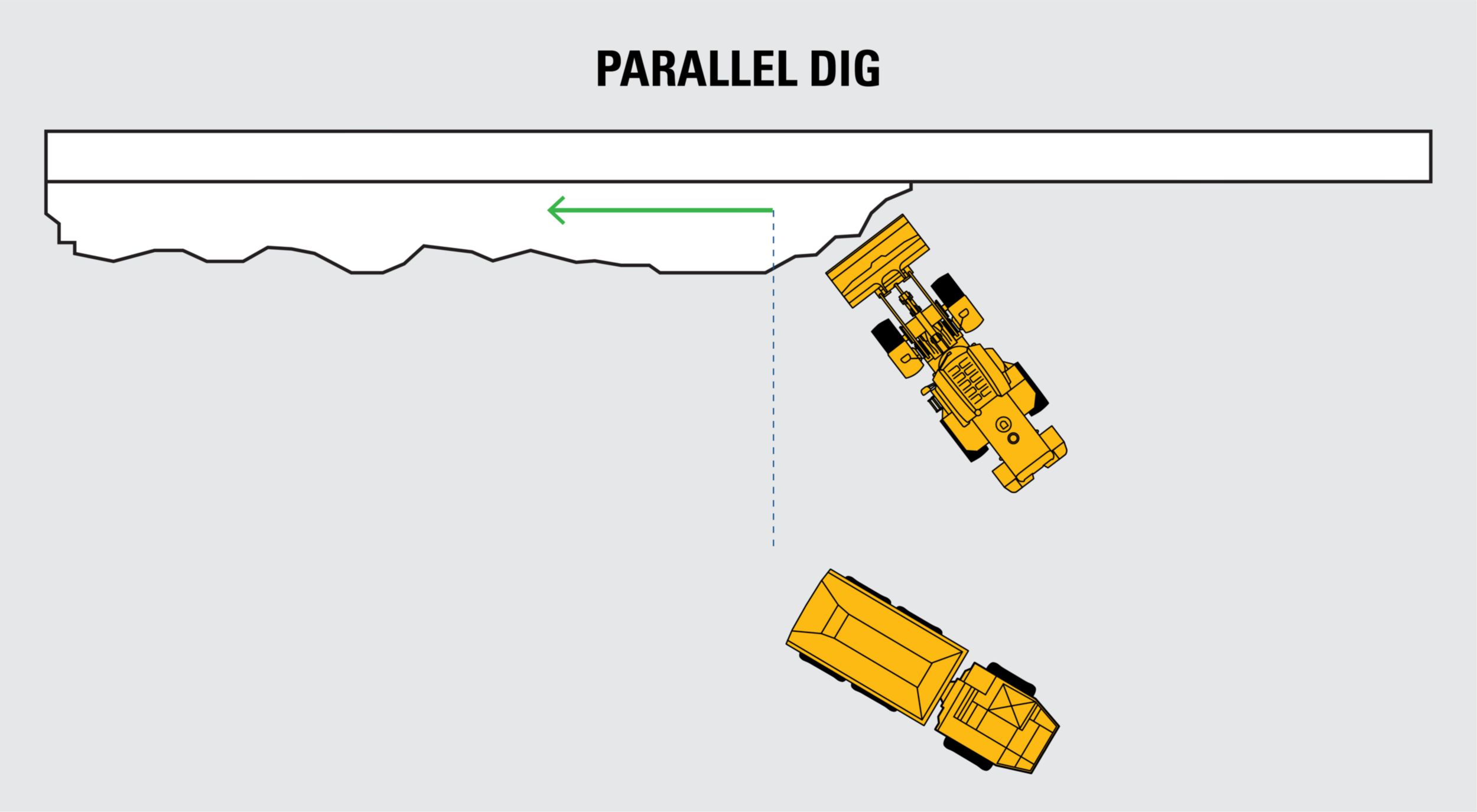

Ideally, you’ll work left to right to give the truck space to approach you — but sometimes you can't. Parallel digs offer narrow dig faces, usually right to left advances. In these situations, spot the truck between 15-20 degrees from perpendicular. That will set up your V-pattern. Then all the basic rules apply: Keep tire rotation under 1 and 1½ revolutions, stay in first gear, approach the face straight but approach the truck with about 5 degrees articulation to dump your load, and make sure the load is centered in the truck.

Equipment Training Solutions

Looking for more detail and operator tips? Cat® Equipment Training Solutions can help. Cat ETS offers operator tips and tricks that can maximize efficiency and save you time and money. Sign up for ETS operator training here.

Popular Articles About Wheel Loaders

Get the most from your wheel loader with operating tips, safety advice, maintenance help and much more.

-

Optimize Wheel Loader Performance and Productivity

How do you optimize Wheel Loader Performance and Productivity? Take a look.

Learn More -

The "Value" in a Customer Value Agreement

Check out these 4 ways a Customer Value Agreement helps your equipment and your business.

Read Article -

Mobile Goes Mainstream

Cat mobile apps make it easy to track equipment location, use, health and more.

Read Article -

Your Equipment Is a Reflection of Your Brand

Keep your equipment in good running condition to maximize uptime and reduce operating costs.

Read Article