Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Read Profile

Product Overview

Cat Engine Overview

Gallery

Related Profiles

Power Profile

CUSTOMER:

Global Pump

PRODUCT:

12GHH Global High Performance High Head Pump

LOCATION:

Davison, Michigan

SCOPE OF ENGINE USE:

Cat® C18 Tier 4 Final, EU Stage V

BUILDING FROM THE BOTTOM UP

Recently, mining activity has increased across the country. With more mines needing to push deeper, the need for groundwater management has heightened. High head centrifugal diesel pumps are often required to run continuously, potentially pumping many thousands of gallons per minute. If one of these pumps fails, the entire pumping system could be flooded. It’s essential to have a pump with a robust, reliable design that’s able to operate through various conditions. Global Pump rose to the occasion to create a pump for these specific demands.

Global Pump was formed in 1997 from Mersino Dewatering, Inc., the Mersino family’s business. Nine years prior, the parent company was founded to install groundwater dewatering systems with sub-grade pumping systems. Unsatisfied with the diesel pumps being purchased from other manufacturers, founder Rod Mersino set out to build a better product.

More Flow, Less Fuel

That’s the approach that Global Pump has taken to its entire product line, including the portable 12GHH Global High Performance High Head pump. Used in a variety of pumping applications, including dewatering, sewer bypass and flood control, the 12GHH can deliver max flows of 7,950 gallons per minute and has a shut-off head approaching 700 feet. The double volute design means that water flows more smoothly through two passages inside the pump to balance out the pressure that would otherwise increase inside the shaft, while a state-of-the-art enclosed impeller secures high efficiency for major fuel savings.

“Our pumps are not only rugged and capable of uninterrupted operation, they also help customers save tremendous amounts of money on fuel consumption due to their efficiency. In many cases, the operational cost savings are enough to pay for a pump purchase in the course of only one year,” noted Gino Mersino, president of Global Pump.

Pumping to the Limit

Serving the rental and end user markets across all of North America and into South America, Global Pump knew that their products had to withstand more than just routine wear and tear. They specifically set out to design the most rugged pump manufactured with only top quality materials. Cast steel is the standard construction for the 12GHH, which allows for field weld repairs that would not otherwise be possible with other alloys. And recently, Global Pump made the 12GHH available in a new high-grade duplex stainless steel. The CD4MCu alloy construction offers this 12GHH model superior corrosion and abrasion resistance, when facing gritty acidic and alkaline pumpage.

“We’ve invested more into our products so that we always put forth the best and most reliable performing product. When customers see our pumps in action, they observe first-hand the difference that can make,” Mersino commented.

Powering Up Full Pumping Capabilities

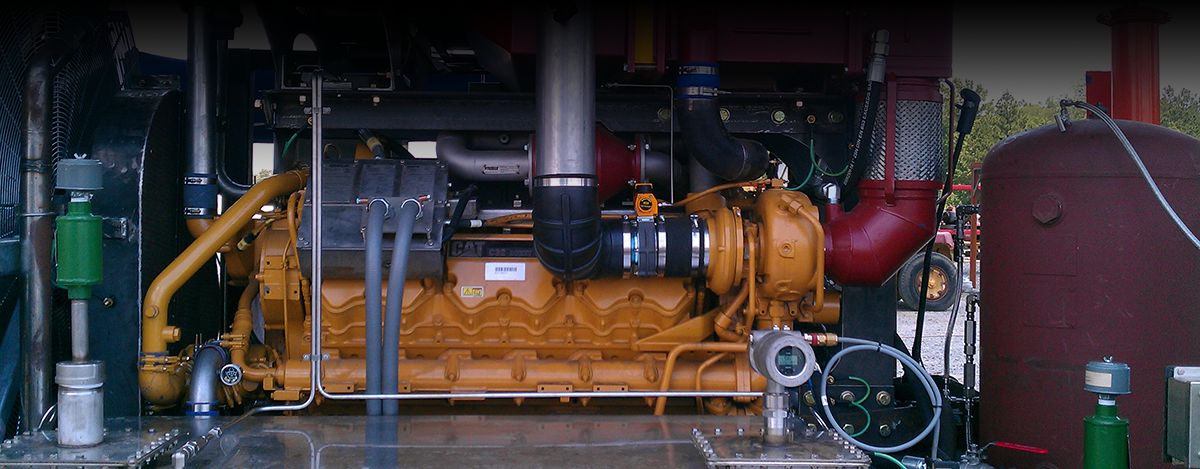

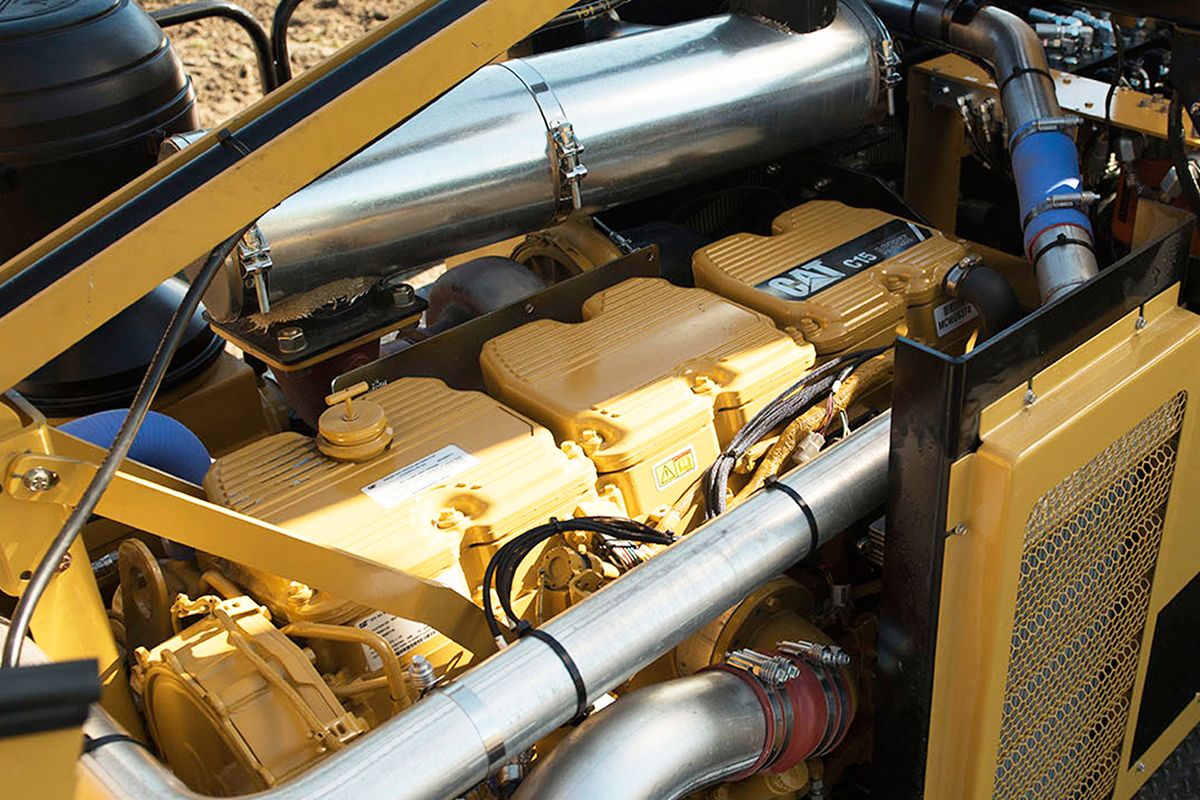

Global Pump’s engineering team selected and equipped the 12GHH with a Cat® C18 Tier 4 Final, EU Stage V diesel-driven engine, which has been proven to be exceptionally reliable for even the most strenuous pumping applications. Maxing out at 800 horsepower, the C18 aids the 12GHH by maintaining peak operating speeds in these situations that otherwise could result in catastrophic damage to the pump end.

“The Cat C18 not only provides us with the higher horsepower we need, but it also serves as a longer-life asset while meeting all clean-air requirements for Tier 4. We’ve had exceptional performance with it,” Mersino shared.

Say When and Where for Service

Since entering the business, Global Pump has had a close relationship with Caterpillar. Michigan Cat helped select the C18 engine and has since continued to support new modifications. But that’s not all that Global Pump relies on their Cat dealer for. Their technical support has helped Global Pump assist clients in remote regions around the world.

Product Overview

- Global Pump 12GHH pumps are ideal for a wide range of applications where high heads and pressures are required, including dewatering, flood control, sewer bypass, fracking and jetting.

- Capable of delivering maximum flows of 7,950 gallons per minute and a maximum total head of 648 feet while handling solids up to 2.5 inches in diameter.

- Double volute design allows water to flow more smoothly through two passages inside the pump to balance out pressure. Also features a state-of-the-art impeller to secure major fuel savings.

- Standard models are constructed with cast steel, which allows for field weld repairs that would not otherwise be possible with other alloys. A new high-grade duplex stainless steel alloy construction is also offered, which offers superior corrosion and abrasion resistance when facing gritty acidic and alkaline pumpage.

- Powered by a Cat® C18 Tier 4 Final, EU Stage V diesel-driven engine for exceptional reliability in even the most strenuous pumping applications while meeting all clean-air requirements.

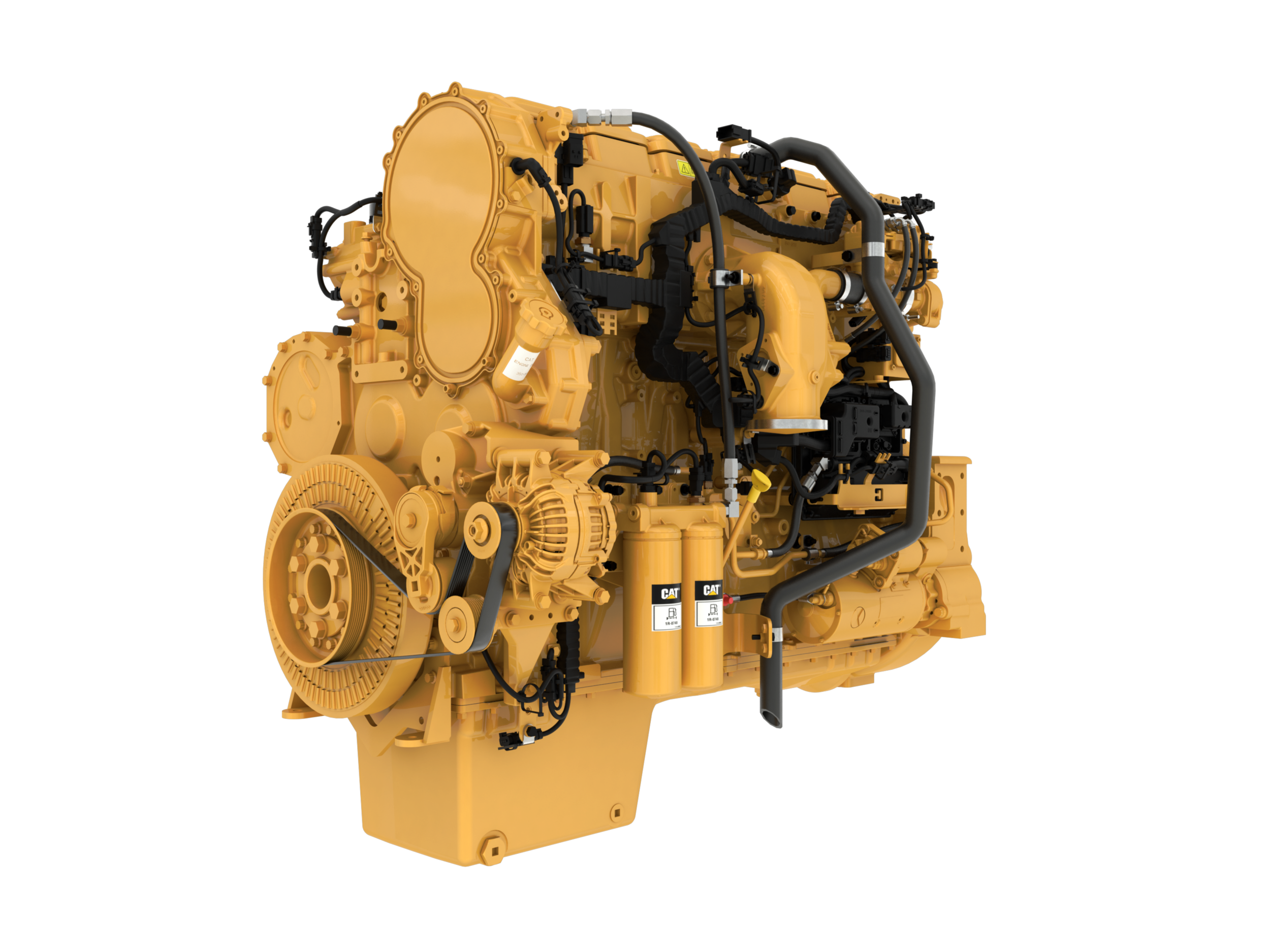

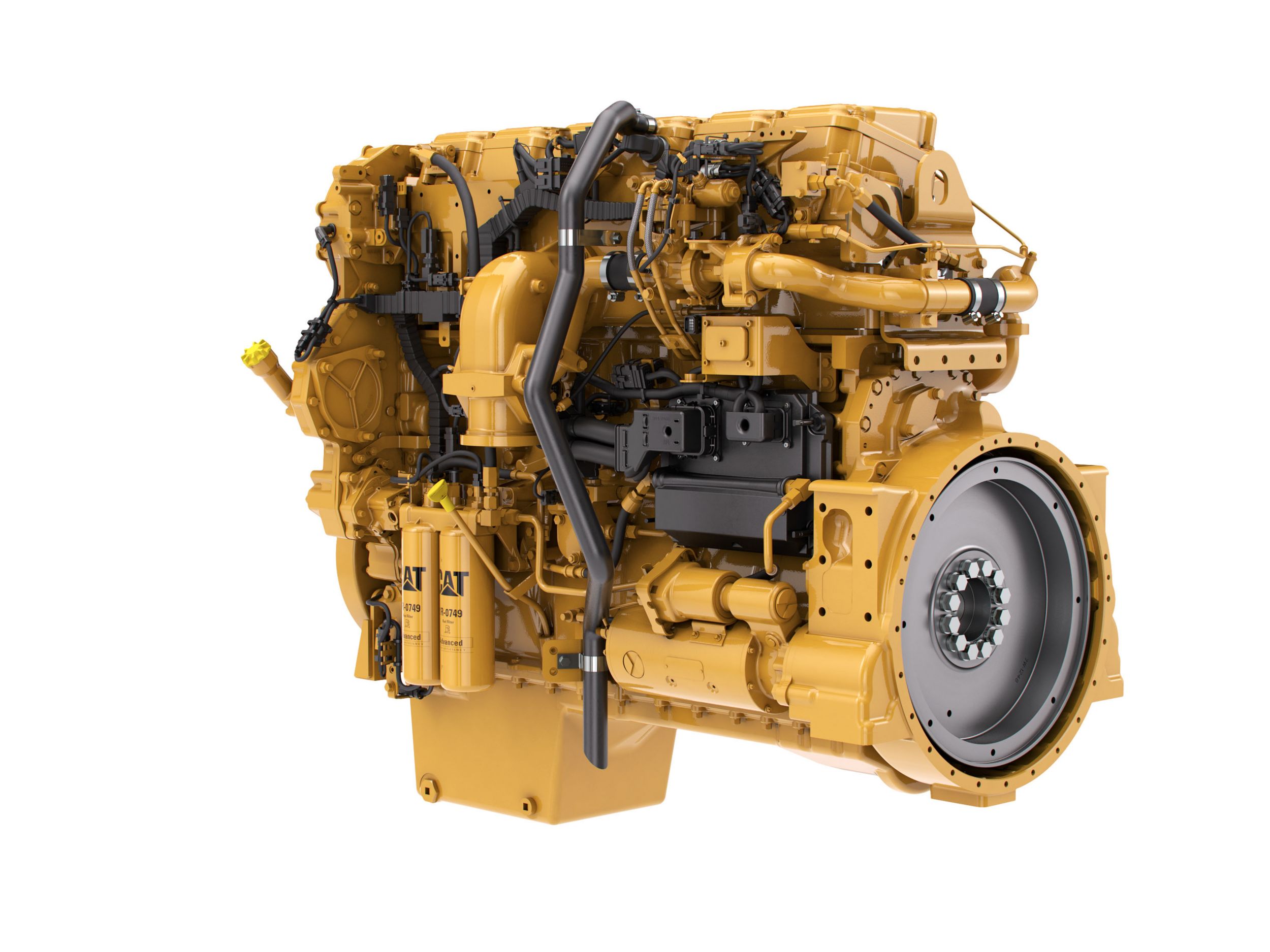

Cat® Engine Overview

- 6-cylinder, 18.1-liter industrial engine is offered in power ratings up to 800 hp (597 kW) and peak torque 3710 Nm (2736 lb-ft) and provides a compact, flexible and quiet engine system that’s ideal for your equipment application.

- The Cat® C18 is designed for optimal power and torque with a proven aftertreatment reducing the cost of installation and ownership while providing maximum uptime.

- Common core engine shared with other Cat industrial engine models offers common machine interfaces and controls architecture. Allows customers to develop commonality in products, parts and service among equipment in their fleets.

- Engine is designed for low parts and labor maintenance requirements, reducing overall cost of ownership.

- The modular engine platform offered by the C18 engine complements a global customer base while providing factory solutions to reduce equipment manufacturers’ design and installation costs.

Compare Models

-

- Maximum Power

- 580 HP

- 433 kW

- Maximum Torque

- 1958 lb-ft @ 1400 rpm

- 2655 Nm @ 1400 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C15

Learn More -

- Maximum Power

- 800 HP

- 597 kW

- Maximum Torque

- 2736 lb-ft @ 1300 rpm

- 3710 Nm @ 1300 rpm

- Emissions

- EU Stage V

- EU Stage V

C18

Learn More -

- Maximum Power

- 1050 HP

- 783 kW

- Maximum Torque

- 3448 lb-ft @ 1200 rpm

- 4674 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C27

Learn More

Power Profile Image Gallery

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more -

Mobile Track Solutions MTS 3630T and the 3630W - Cat® C18 Engine

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

Eagle Crusher UltraMax® 1200-CC Crushing Plant - Cat® C9.3B Engine

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

MudPuppy Pumps - Cat® C7.1 Engines

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

Infrastructure Contractors/MTS 3630T Construction Tractor - Cat® C18 Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more -

Gorman-Rupp Cat Powered Pumps

Learn more -

Diamond Products® CC5048DC saw - Cat® C2.2 and C1.7 Engines

Learn more -

Mobile Track Solutions connectivity - Cat® C18 Engines

Learn more -

Allmand Maxi-Lite Tower - Cat® C1.1 Engine

Learn more -

Barco Pump - Cat® C2.2 and C3.6 Engines

Learn more -

Vermeer terrain leveler - Cat® C18 Engine

Learn more -

Supreme Blasting Power from Sullair

Learn More -

Trenching Through the Toughest Terrains with Trencor

Learn More -

Pioneer Pump Four-Inch and Six-Inch Pumps

Learn More -

HPSI Model 500 Vibratory Hammer

Learn More -

Doosan Portable Power Large Air Compressors

Learn More -

Morooka MST880VDL and MST880VD

Learn more -

LMR Landfill Tippers – Powered by Cat® Reman

Learn More -

Chip and crush waste with Rotochopper

Learn More -

Do more with Wetland Equipment Company and Cat.

Learn More -

Diamond Z Tub and Horizontal Grinders

Learn more -

Diamond Products® PC1505XL Pavement Grinder & Groover and PC6004EC Grinder

Learn more -

Diamond Products® CC4948DC saw - Cat® C1.7 Engine

Learn more -

Xtreme Polesetter II Digger and Bucket

Learn More -

Diamond Products® CC6774DCV Walk Behind Saw

Learn More

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.