Dimensions

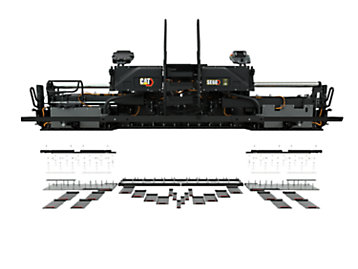

| Paving Range with SE60 FM | 3 m - 7.8 m (10' - 25' 6") 3 m - 7.8 m (10' - 25' 6") |

| Paving Range with SE60 V | 3 m - 7.65 m (9' 10" - 25') 3 m - 7.65 m (9' 10" - 25') |

| Paving Range with SE60 V XW | 3 m - 7.5 m (10' - 24' 6") 3 m - 7.5 m (10' - 24' 6") |

| Paving Range with SE60 VT XW | 3 m - 6 m (10' - 19' 6") 3 m - 6 m (10' - 19' 6") |

| Operating Length | 22.3 ft 6.8 m |

| Operating Width | 10.8 ft 3.3 m |

| Overall Height | 12.3 ft 3.8 m |

| Transport Length | 20.9 ft 6.4 m |

| Transport Width | 11.9 ft 3.6 m |

| Transport Height | 9.8 ft 3 m |