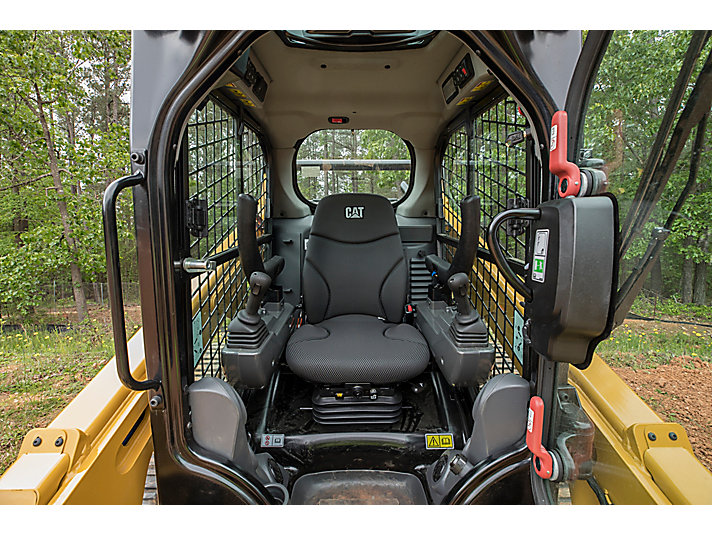

The industry leading sealed and pressurized cab option provides the operator with a cleaner and quieter operating environment with excellent work tool visibility. Continuing the industry leading trend, the D3 Series also includes as standard, seat mounted adjustable joystick controls for operator comfort.

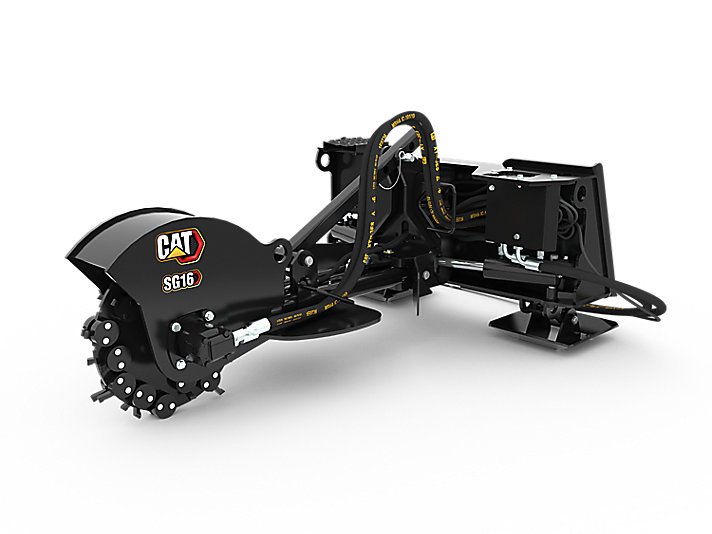

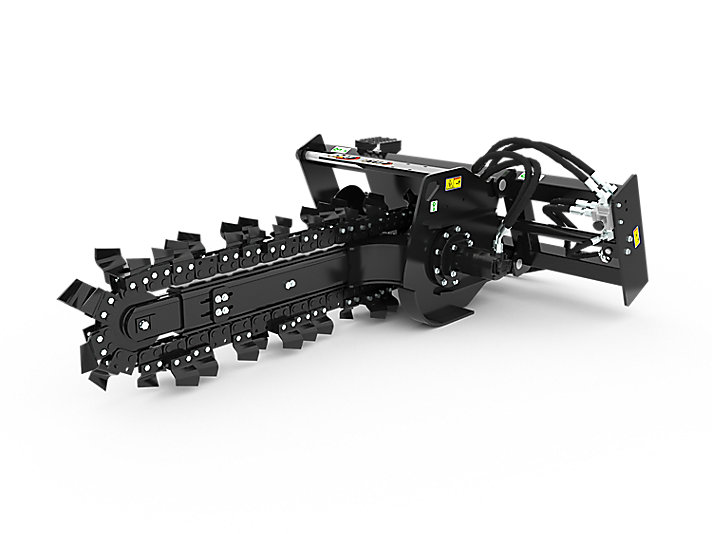

High performance power train provides maximum performance and production capability through the Electronic Torque Management system, standard two speed travel and an electronic hand/foot throttle with decel pedal capability.

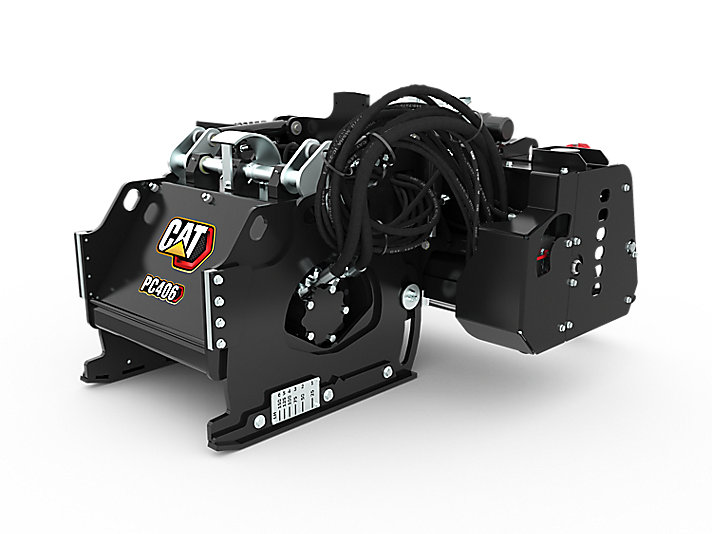

Cat® “Intelligent Leveling” system provides industry leading technology, integration, and available features such as dual direction self level, work tool return to dig, and work tool positioner.

Maximize machine capability and control with the available Advanced Display, providing on-screen adjustments for implement response, hystat response and creep control. Also features multi-language functionality with customizable layouts, security system and rearview camera.