No wasted opportunities

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- Rotochopper’s largest grinder, the B-66, was developed to transform everything from whole trees to railroad ties to roofing shingles into engineered fiber products.

- When demand for grinders increased in hurricane clean-up and pipeline land-clearing applications, the company redesigned the B66 to tackle bigger jobs faster and more efficiently. Thus, the B-66L was created and powered by a Cat® C27 industrial engine.

- Featuring a lower and longer infeed hopper, a more aggressive powerfeed and increased input capabilities, the B-66L can grind large, abrasive feedstock materials to a precisely defined size in just one pass.

- The C27 came with a reputation for reliable, durable performance, and Rotochopper worked with Cat dealer Ziegler to integrate a reversing fan that keeps the radiator clean, minimizing plugging in dirty environments.

- Rotochopper also appreciates the support it gets from Ziegler, which not only helped configure the C27 for the B-66L but also continues to stand behind the engine no matter where it’s doing hard work.

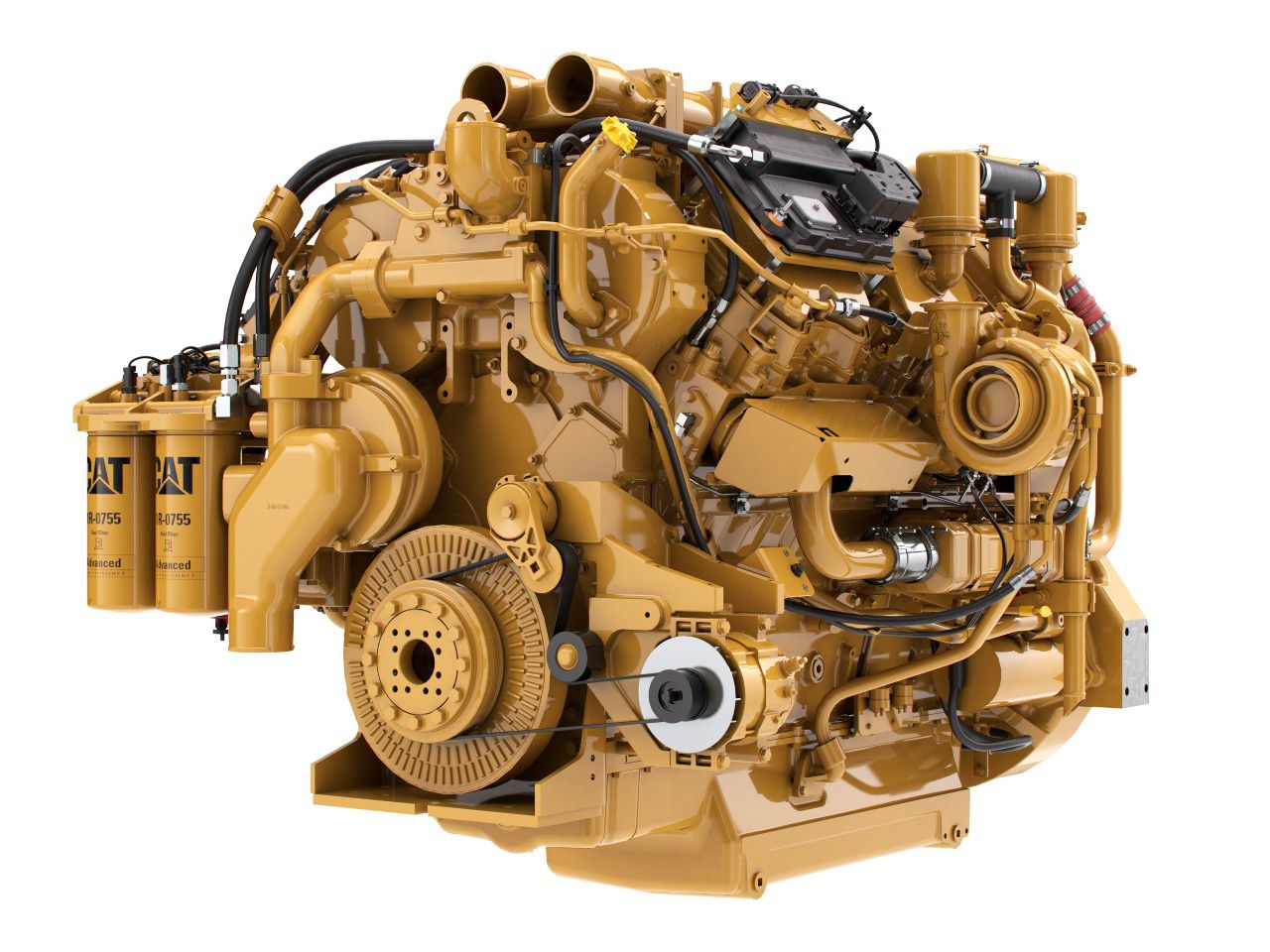

Cat® Engine Overview

- The Cat® C27 Industrial Diesel Engine is offered in ratings up to 1050 hp (783 kW) and peak torque 4674 Nm (3451 lb-ft). The power-dense Cat C27 is a fully-configurable common core engine that makes installation across a wide variety of applications simple.

- With options like rear-mounted turbos and engine-mounted aftertreatment, it's now easier than ever to install. And because the C27 is DEF-free, there's even more room to maneuver under the hood.

- Featuring a clean emissions module, the Cat C27 uses DOC-only technologies to keep the engine — and the air around it — cleaner, not only making for a more efficient machine, but also a safer job site. Available as remote mounted aftertreatment for great flexibility or optional engine mounted aftertreatment for ease of installation.

- Dual certified U.S. EPA Tier 4 Final/EU Stage V offers a single installation globally for all countries requiring EU Stage V or similar emissions standards. U.S. EPA Tier 2 equivalent ratings available for countries that permit this level of emissions.

- Superior dealer service and support, scheduled maintenance and a five year warranty: it’s what Cat C27 owners network can expect with their new engine.

Compare Models

-

- Maximum Power

- 800 hp

- 597 kW

- Maximum Torque

- 2736 lb-ft @ 1300 rpm

- 3710 Nm @ 1300 rpm

- Emissions

- EU Stage V

- EU Stage V

C18

Learn More- Maximum Power

- 1050 hp

- 783 kW

- Maximum Torque

- 3448 lb-ft @ 1200 rpm

- 4674 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C27

Learn More- Maximum Power

- 1200 hp

- 895 kW

- Maximum Torque

- 4056 lb-ft @ 1200 rpm

- 5499 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C32

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

B-66L Grinder

LOCATION:

St. Martin, Minnesota

SCOPE OF ENGINE USE:

Cat® C27 U.S. EPA Tier 4 Final and Tier 2 Industrial Engines

Cat Dealer

GIVING UNWANTED MATERIALS NEW LIFE

Where others see waste, Rotochopper sees opportunity. In the late 1980s, the company developed a process for converting unwanted newspapers into animal bedding and built its first Rotochopper for the job — a 30-horsepower electric paper-chopping machine — soon after. Additional uses quickly became apparent, and Rotochopper’s machines grew and evolved to take on jobs like recycling wood pallets, turning wood waste into colored mulch and converting ag residue into biofuels. Today, the company offers a full line of diesel and electric horizontal grinders ranging from 250 to 1,050 horsepower.

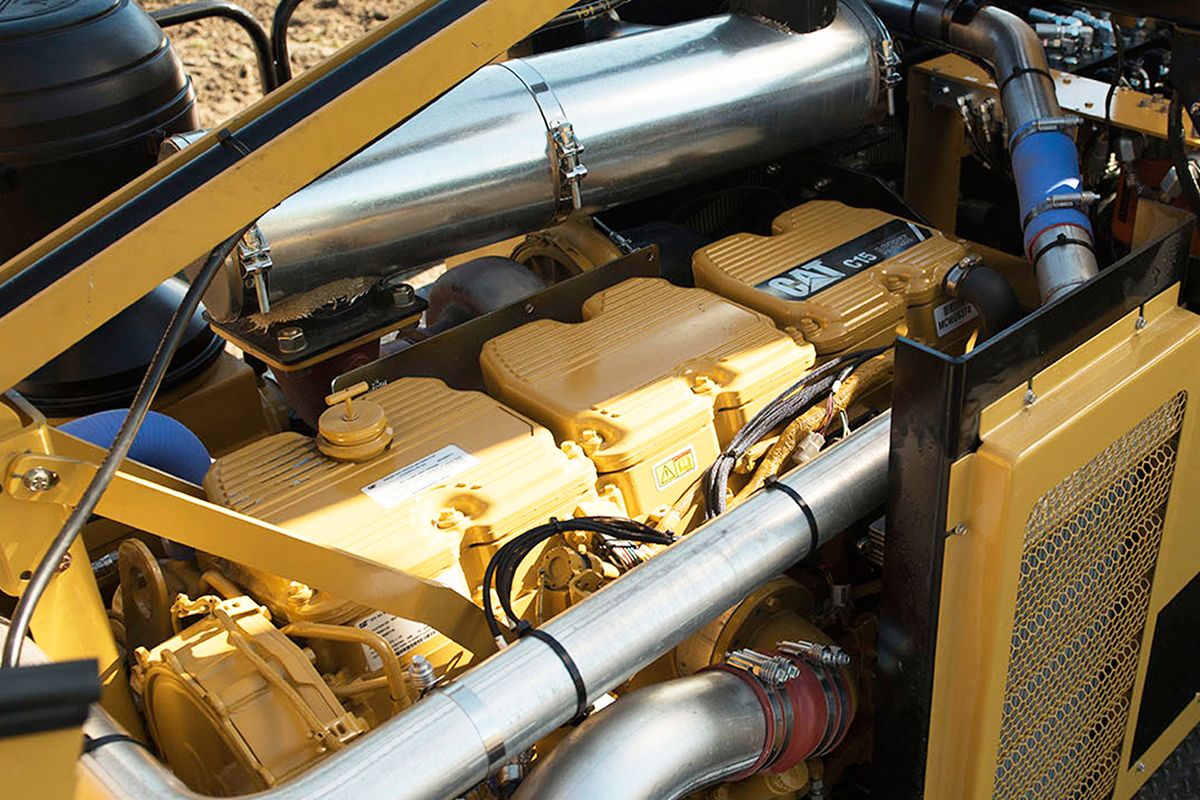

Rotochopper’s largest grinder, the B-66, was developed to transform everything from whole trees to railroad ties to roofing shingles into engineered fiber products. But when demand for grinders increased in hurricane clean-up and pipeline land-clearing applications, the company was convinced it could redesign the machine to tackle these even bigger jobs faster and more efficiently.

The result? The B-66L, powered by a Cat® C27 industrial engine. Featuring a lower and longer infeed hopper, a more aggressive powerfeed and increased input capabilities, the B-66L can grind large, abrasive feedstock materials to a precisely defined size in just one pass. That sets it apart from competitive grinders, which typically require the use of a secondary piece of equipment — like a screener — to produce the right-sized output. Getting the job done with just one machine saves Rotochopper’s customers time and money.

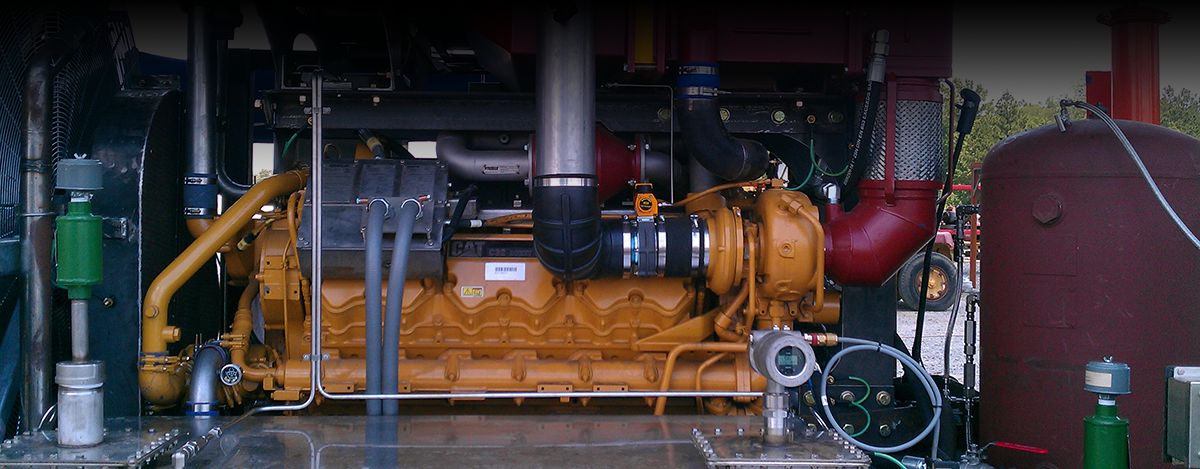

GRINDING AT FULL SPEED

For the land-clearing operations, storm clean-up teams, waste removal companies and mulch producers that rely on the B-66L, maintaining high levels of production is the top priority. That made the 1,050-horsepower Cat C27 engine the perfect power solution for the grinder. “It’s all about getting the material through the machine, and the faster the work gets done, the better,” says Jamey Brick, chief operating officer for Rotochopper. “The C27 ticks all the boxes our customers require in that horsepower range.”

A tough environment calls for a tough design. Because the B-66L works in harsh conditions, filled with dust and damaging materials, Rotochopper built in extra durability — like the StopWatch system that detects un-grindable material and reverses the conveyor before it causes harm. The company wanted an engine that was equally robust. The C27 came with a reputation for reliable, durable performance, and Rotochopper worked with Cat dealer Ziegler to integrate a reversing fan that keeps the radiator clean, minimizing plugging in a dirty environment. “That’s helped keep reliability up,” Brick says.

In-the-field know-how keeps grinders grinding. Just as important as performance on the job is support after the sale. In North America, where most of its products are sold, Rotochopper offers factory-direct service — employing technicians who work exclusively on its grinders. Thanks to the Cat dealer network, the company offers that same level of expertise on the B-66L’s engine.

Two organizations share one commitment to customers. Rotochopper also appreciates the support it gets from Ziegler, which not only helped configure the C27 for the B-66L but also continues to stand behind the engine no matter where it’s out doing hard work. “We place a sticker on every C27 that encourages the local Cat dealer to contact us if they have questions,” says Steve Campen, senior sales engineer at Ziegler. “We share similar DNA with Rotochopper when it comes to customer service. Our job isn’t done until the customer is happy.”

“WITH SOME BRANDS, YOU may get a technician who’s been working on marine engines and doesn’t know what he’s looking at when he climbs up on a grinder, Cat® technicians don’t have that learning curve, because they’re experts on heavy equipment.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more -

Diamond Products CC5049DC saw - Cat® C2.2 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more

Cat® Industrial Engine Support

Your Cat dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION