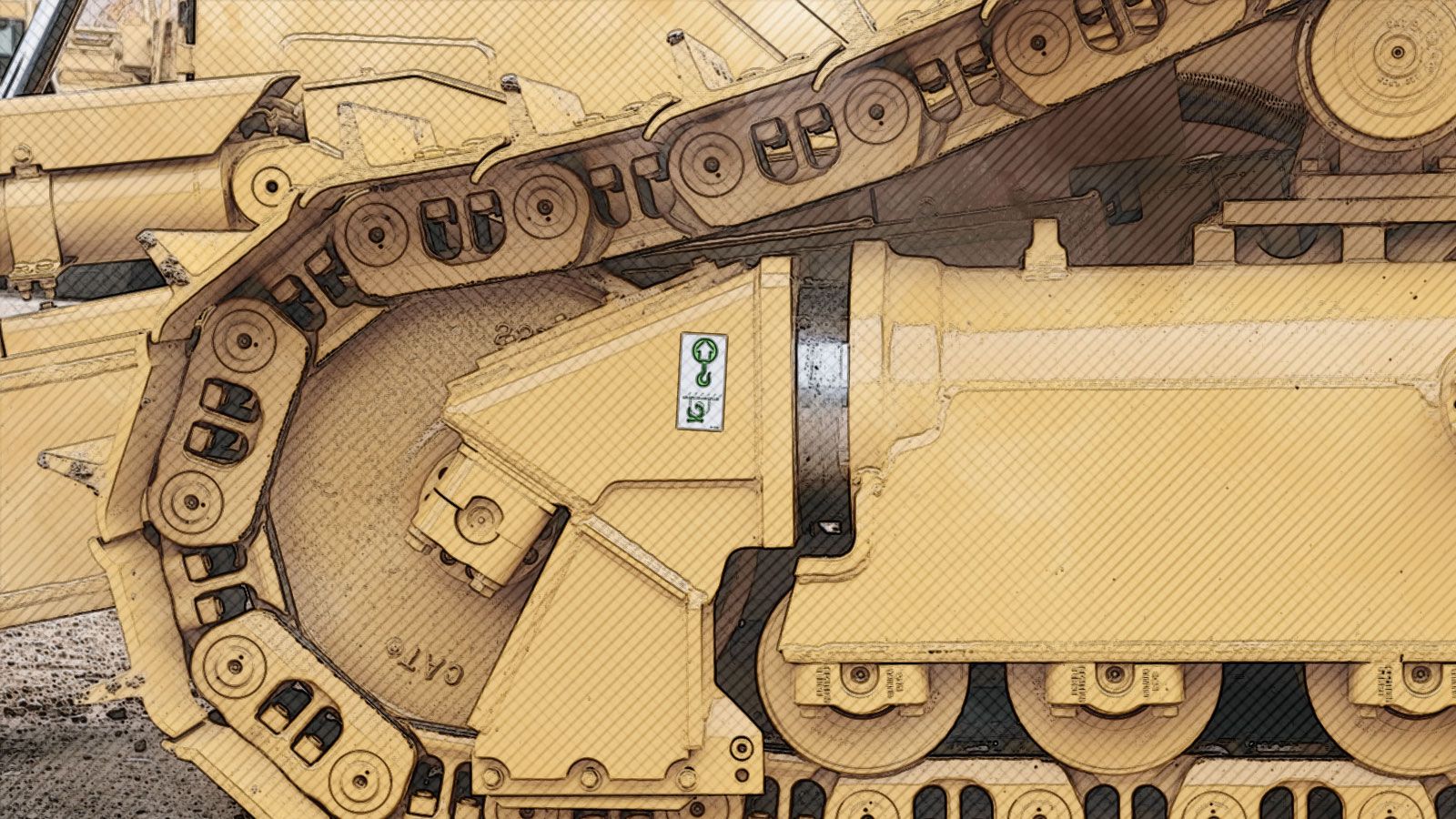

Cat® Undercarriage

LOWER COST. LONGER LIFE.

Undercarriage typically represents an average 50% of a machine’s owning and operating costs, so it makes sense to invest in a system that will deliver the most value. Every Cat® undercarriage is designed by Caterpillar engineers and built to exacting specifications to match your machine and application — and deliver the lowest operating costs.

Construction

Mining

CAT ABRASION™ UNDERCARRIAGE

Cat Abrasion™ is a direct replacement for SystemOne™, featuring design improvements based on real-world applications. Cat Abrasion performs better and lasts 50% longer than conventional undercarriage* in your high-abrasion, low-to-medium impact applications. Available for D3-D6 dozers.

See Cat Abrasion

General Duty Undercarriage

The most affordable undercarriage designed and manufactured by Caterpillar, General Duty delivers low cost per hour in light-duty, low-to-moderate earthmoving applications. Available for D6-D11 dozers, 311-349 excavators and 953-963 track loaders.

Go To General Duty

Heavy Duty Extended Life (HDXL) with DuraLink™ Undercarriage

Built on proven Cat Heavy Duty undercarriage, HDXL with DuraLink™ takes performance to the next level with exceptional wear life and lower cost per hour than competitive brands in tough applications such as medium abrasion and high impact. Available for D6-D11 dozers.

More on HDXL

Rubber Track Undercarriage

Cat rubber tracks improve traction, reduce machine wear, increase operator efficiency and can be customized to the work and terrain. Every rubber track is rigorously tested for fit and performance. Available for 239-299 compact track loaders and 300-310 mini excavators.

View Rubber Tracks

*Compared to Cat Heavy Duty Extended Life (HDXL) undercarriage

General Duty Undercarriage

General Duty undercarriage is recommended for low-to-moderate impact applications where the elevated performance of Heavy Duty undercarriage is not needed. While built to different specifications, General Duty and Heavy Duty components are interchangeable to eliminate retrofits and keep downtime to a minimum. Available for D9-D11 dozers.

See General Duty

HDXL with DuraLink Undercarriage

Heavy Duty Extended Life with DuraLink is engineered with additional wear material, heat treatment and increased sealability before and after bushing turns. Specific enhancements include a link design that reduces scalloping and vibration, increased wear material, and a nut seat window redesign to eliminate cracking. Available for D9-D11 dozers.

Go to HDXL

Heavy Duty Undercarriage

Heavy Duty undercarriage is specifically engineered for hard rock applications where impact levels range from moderate to high. Built for jobs that need a wear life of 5,000 hours or more, it’s tough enough to handle harsh impact applications with wear material designed for long life in abrasive conditions. Available for D9-D11 dozers and 6015-6090 hydraulic mining shovels.

More on Heavy Duty

Undercarriage Repair Options

Undercarriage can amount to as much as 50% of owning and operating costs. Managing and maintaining undercarriage systems and components extends wear life and lowers overall operating costs.

View Brochure

Custom Track Service (CTS)

A poorly managed undercarriage can account for more than half of your machine’s maintenance costs. Why risk it? Maximize your undercarriage life and reduce downtime with CTS Pro. Your Cat dealer uses the latest technology to monitor undercarriage performance and predict wear rates, allowing you to make informed decisions about maintenance, avoid unexpected issues and lower your total costs. Check out this video to see what CTS Pro can do for your operation.

Tips for Undercarriage Maintenance & Management

Undercarriage wear depends on the application, underfoot conditions and skilled operation. The more you know about how to make your undercarriage last, the more money you’ll make. Find tips, selection guides and more for your excavator or dozer below.

Excavator Tips

Dozer Tips