Weights

| Operating Weight - With ROPS/FOPS | 38405 lb 17420 kg |

| Weight - Drum with ROPS/FOPS | 26559 lb 12047 kg |

| Weight - Drum with Cab | 26559 lb 12047 kg |

Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

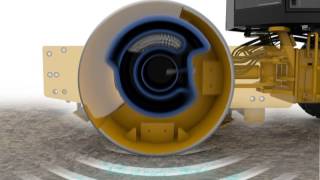

Up to 15% fuel savings with eco-mode, exclusive pod-style vibratory design offering 3 year/3000 hour service intervals, and a no-maintenance hitch with sealed-for-life bearings.

On-board compaction measurement helps take guesswork out of the process with exclusive MDP technology that gives compaction readings; scalable solutions including mapping and machine-to-machine communication keep jobsite connected.

Visibility is enhanced by the new rear vision camera; standard tiltable steering column gives the operator more flexibility, and our integrated backlit display console turns with seat.

Key Specs

The CS76B provides exceptional performance for granular soil compaction applications.

Up to 15% fuel savings with eco-mode, exclusive pod-style vibratory design offering 3 year/3000 hour service intervals, and a no-maintenance hitch with sealed-for-life bearings.

On-board compaction measurement helps take guesswork out of the process with exclusive MDP technology that gives compaction readings; scalable solutions including mapping and machine-to-machine communication keep jobsite connected.

Visibility is enhanced by the new rear vision camera; standard tiltable steering column gives the operator more flexibility, and our integrated backlit display console turns with seat.

| Operating Weight - With ROPS/FOPS | 38405 lb 17420 kg |

| Weight - Drum with ROPS/FOPS | 26559 lb 12047 kg |

| Weight - Drum with Cab | 26559 lb 12047 kg |

| Compaction Width | 84 in 2134 mm |

| Curb Clearance | 20.7 in 526 mm |

| Drum Width | 60.4 in 1535 mm |

| Ground Clearance | 17.2 in 437 mm |

| Static Linear Load - With ROPS/FOPS | 316.4 lb/in 56.5 kg/cm |

| Travel Speed - Maximum | 7 mile/h 11.4 km/h |

| Turning Radius - Inside Drum Edge | 12.1 ft 3.7 m |

| Gross Power | 173.5 HP 129.4 kW |

| Engine Model | Cat C4.4 Cat C4.4 |

| Net Power - ISO 9249 | 145.8 HP 108.7 kW |

| Net Power - SAE J1349 | 145.1 HP 108.2 kW |

| Stroke | 5 in 127 mm |

| Bore | 4.1 in 105 mm |

| Overall Length | 20.1 ft 6.1 m |

| Overall Width | 7.8 ft 2.4 m |

| Height - With ROPS/FOPS | 10.1 ft 3.1 m |

| Drum Width | 84 in 2134 mm |

| Drum Diameter | 60.4 in 1535 mm |

| Wheel Base | 9.5 ft 2.9 m |

| Centrifugal Force - Maximum | 75234 lb 335 kN |

| Centrifugal Force - Minimum | 35153 lb 156 kN |

| Nominal Amplitude - High | 0.083 in 2.1 mm |

| Nominal Amplitude - Low | 0.039 in 0.98 mm |

| Variable Frequency Option Range | 23.3 - 28 Hz (1400-1680 vpm) 23.3 - 28 Hz (1400-1680 vpm) |

| Vibratory Frequency - Standard | 28 Hz (1680 vpm) 28 Hz (1680 vpm) |

| Fuel Tank Capacity | 88 gal (US) 332 l |

| Tires | 23.1 x 26 23.1 x 26 |

Use the comparison tool to compare detailed specs of Cat and competitor models.

COMPARE ALL MODELSFull specifications, product brochures and more. Sign up below for additional information. Or for instant access, you can skip this form.

CS76B Vibratory Soil Compactor

CS76B Vibratory Soil Compactor

CS76B Introduction

Machine Drive Power (MDP)

Achieving Quality Compaction

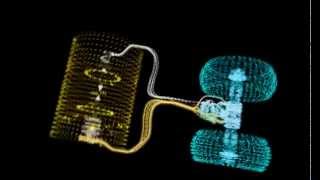

Dual Pump Propel System

Eco-Mode

Shell Kit and Blade Options

Product Link Option

Leverage Caterpillar connected data and security principles to improve efficiencies, increase productivity and make your business more profitable.

When your jobsite requires consistent and accurate compaction,

Command is right for the job.

Dramatically boost consistency, coverage, and safety through semi-autonomous equipment solutions with the all new Cat® Command for Compaction.

Cat Command for Compaction is an operator-assisted, semi-autonomous technology that automates the compaction process based on operator inputs. Command controls the speed, direction, steering, and vibration system of the soil compactor to promote consistency in compaction.

When your jobsite requires consistent and accurate compaction,

Command is right for the job.

Dramatically boost consistency, coverage, and safety through semi-autonomous equipment solutions with the all new Cat® Command for Compaction.

Cat Command for Compaction is an operator-assisted, semi-autonomous technology that automates the compaction process based on operator inputs. Command controls the speed, direction, steering, and vibration system of the soil compactor to promote consistency in compaction.

Cat Compact with Machine Drive Power (MDP) is an energy-based measurement system that correlates compaction with rolling resistance to provide an indication of soil stiffness. An optional mapping system helps operators visualize work as it occurs.

Cat Compact with Machine Drive Power (MDP) is an energy-based measurement system that correlates compaction with rolling resistance to provide an indication of soil stiffness. An optional mapping system helps operators visualize work as it occurs.

Cat® Inspect allows you to access your equipment data on your mobile device. This easy-to-use app lets you capture inspection data and integrates with your other Cat data systems, so you can keep a close eye on your fleet. More than one million inspections are completed each year, providing convenience and accountability to equipment owners.

Cat® Product Link™ wirelessly connects you to your equipment giving you valuable insight into how your machine or fleet is performing. Information such as location, hours, fuel usage, productivity, idle time, and diagnostic codes are made available through online web applications so that you can make timely, fact-based decisions to maximize efficiency, improve productivity, and lower the cost of owning and operating your fleet. Available with satellite or cellular connectivity.

VisionLink® is a cloud-based software application that takes the guesswork out of fleet management with key insights to maximize performance - regardless of fleet size or equipment manufacturer. Receive equipment data seamlessly to your desktop or mobile device, all from a convenient centralized solution to make informed decisions at every turn.

Cat® Inspect allows you to access your equipment data on your mobile device. This easy-to-use app lets you capture inspection data and integrates with your other Cat data systems, so you can keep a close eye on your fleet. More than one million inspections are completed each year, providing convenience and accountability to equipment owners.

Cat® Product Link™ wirelessly connects you to your equipment giving you valuable insight into how your machine or fleet is performing. Information such as location, hours, fuel usage, productivity, idle time, and diagnostic codes are made available through online web applications so that you can make timely, fact-based decisions to maximize efficiency, improve productivity, and lower the cost of owning and operating your fleet. Available with satellite or cellular connectivity.

VisionLink® is a cloud-based software application that takes the guesswork out of fleet management with key insights to maximize performance - regardless of fleet size or equipment manufacturer. Receive equipment data seamlessly to your desktop or mobile device, all from a convenient centralized solution to make informed decisions at every turn.