Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Just Add Water

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- Today, Custom Dredge Works manufactures cutterhead suction, chain ladder, deep digging and electric-powered dredges — along with booster pumps and dewatering bucket wheels — for dredging contractors and mining operations in every U.S. state and around the world.

- Custom Dredge Works tailors every dredge to the owner’s preferences including cab size, controls, lights, cranes, pumps, winches and even the color scheme. Owners have their choice of diesel, electric or natural gas engines as well.

- Having a wide range of Cat® industrial power engines to select from makes it easy for the company to give dredge owners exactly what they need. Cat engines are recommended due to availability of replacement parts and serviceability at dealers around the world.

- When properly maintained, the lifespan of CDW dredges can reach up to 40 years, meaning the engines powering them need to stand the test of time. Using Caterpillar’s global dealer network allows for reliable support in maintaining optimal uptime for equipment and getting jobs done no matter the location.

Cat® Engine Overview

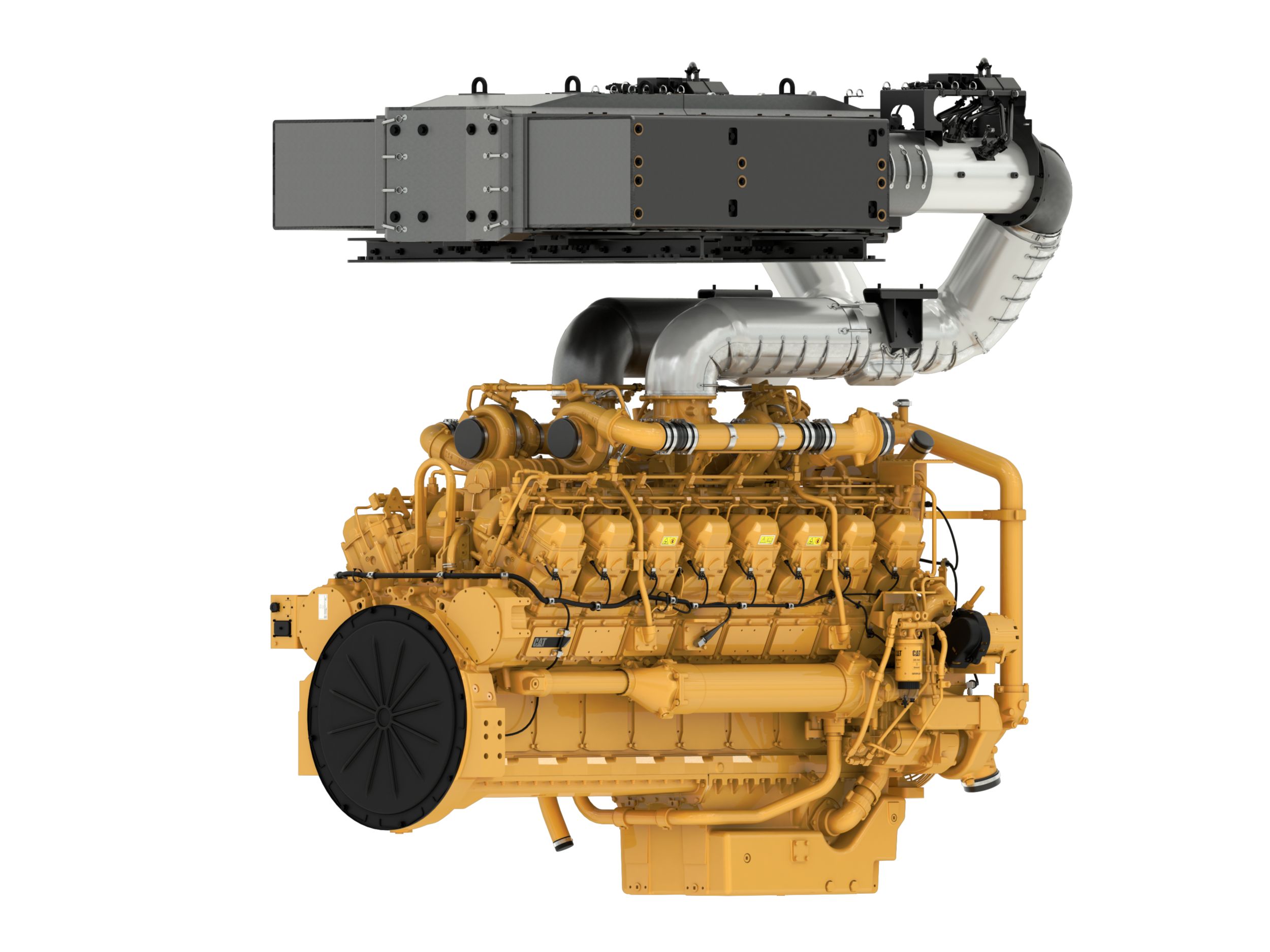

- The Cat® C32 industrial engine is offered in power ranges up to 1200 hp (895 kW) and peak torque 5500 Nm (4056 lb-ft) and allows for platform downsizing while maintaining reliability and durability.

- The C32 engine is ideal for tough industrial and construction applications such as dredges, chippers, grinders, emergency water pumps and rock drills among other applications requiring continuous peak performance under the most demanding conditions.

- The key to success for any machine is avoiding downtime as much as possible. Thanks to the DEF-free, dual-can DOC with transparent regeneration offered by the 32 engine, operators can stay focused on being productive for the long haul.

- When it comes to making the engine installation process smoother for Original Equipment Manufacturers (OEMs), look to the C32 engine. Using innovative technology solutions, the C32 was created to eliminate the need for thermal management and Diesel Exhaust Fluid (DEF), reducing the size of the overall engine package. And thanks to flexible aftertreatment mounting options, installing such a large engine just got a lot less complicated.

- Optimized to meet some of the most demanding operating cycles of just about any machine, the DEF-free Cat C32 helps owners and operators save on operating costs while also remaining maintenance-free for the engine's lifetime.

Compare Models

-

- Maximum Power

- 1050 HP

- 783 kW

- Maximum Torque

- 3448 lb-ft @ 1200 rpm

- 4674 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C27

Learn More -

- Maximum Power

- 1200 HP

- 895 kW

- Maximum Torque

- 4056 lb-ft @ 1200 rpm

- 5499 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C32

Learn More -

- Maximum Power

- 2100 HP

- 1566 kW

- Maximum Torque

- 8275 lb-ft @ 1200 rpm

- 11220 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final, EU Stage V

- U.S. EPA Tier 4 Final, EU Stage V

3516E

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

Dredger

LOCATION:

Topeka, Kansas

SCOPE OF ENGINE USE:

Cat® C9-3512 Industrial Engines

CAT DEALER:

FLOATING AN IDEA

A love of cars led CJ Jones to open a metalworks business in North Topeka, Kansas, in the early 1980s. He built MidWestern Metals (MWM) into an expert metal fabrication shop, completing projects for Ford Motor Company, Dearborn Midwest Conveyor and the U.S. National Guard Helicopter Division, among others.

CJ’s son, John, was determined to become a stockbroker after college — but after a single day on the job, he realized his heart was still in the shop with his dad. It wasn’t long before he found himself joining MWM and looking for a niche of his own. He found it when a local mining operation asked the company to overhaul and upgrade a dredge.

The project was so successful the mine requested that MWM build a facsimile of the existing dredge and then a second dredge from scratch. With that, a new company — Custom Dredge Works — was formed in 2001. In the two decades since, the operation has grown into one of the U.S.’s leading manufacturers of state-of-the-art custom dredges. They’re used to harvest valuable minerals, create or deepen ports and waterways, assist with fl ood or erosion control, remove contaminated materials from areas affected by chemical spills or stormwater surges and much more.

Today, from land-locked Topeka, Kansas, Custom Dredge Works and its team of 100-plus employees manufacture new cutterhead suction, chain ladder, deep digging and electric-powered dredges — along with related equipment like booster pumps and dewatering bucket wheels — for dredging contractors and mining operations in every U.S. state and around the world.

THE CHOICE IS CLEAR

In his metalworks shop, CJ Jones had been a faithful Cat® customer for decades, but the first dredge he and his son overhauled was equipped with another brand’s engine. “We had to jump through a lot of hoops with them,” he says. So when Custom Dredge Works began building dredges from scratch, the company turned to its preferred manufacturer, Caterpillar, to supply engines for both dredges and the booster pumps that power them.

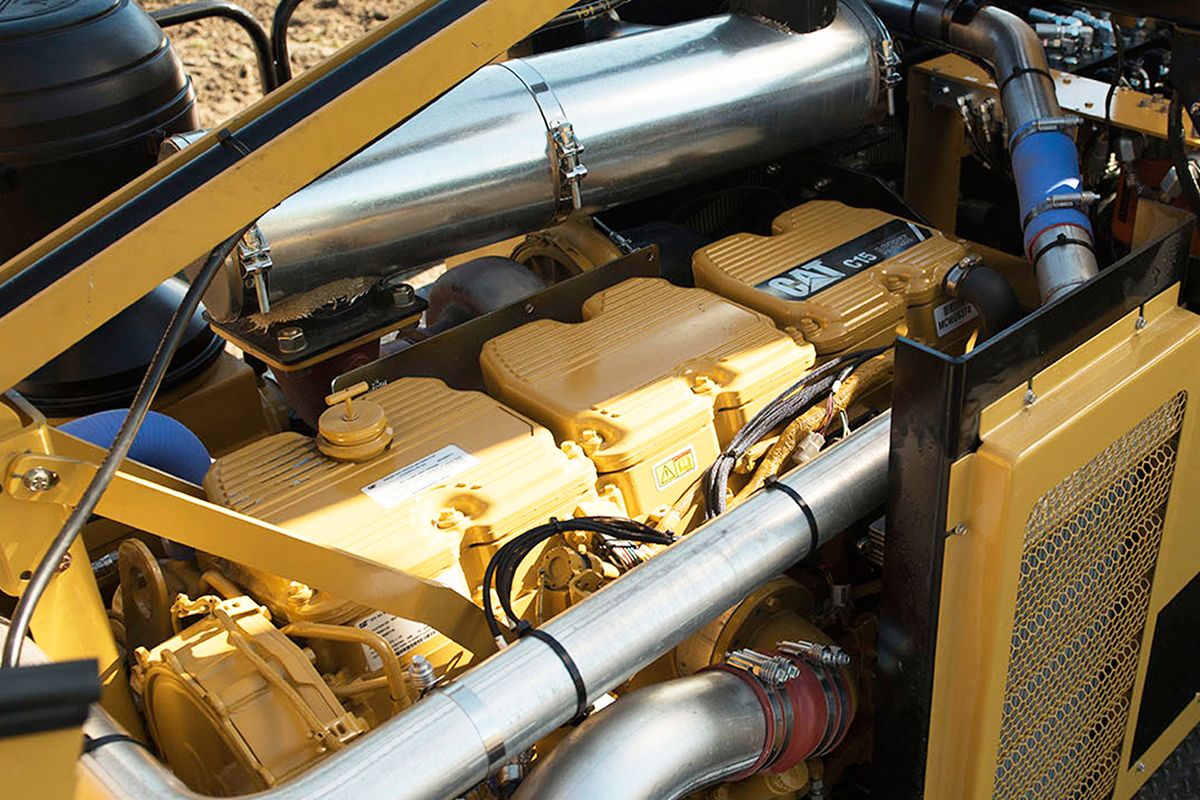

Options across the board. As the name makes clear, Custom Dredge Works tailors every dredge to the owner’s preferences. That includes cab size, controls, lights, cranes, pumps, winches and even the color scheme. Owners have their choice of diesel, electric or natural gas engines, too. “We recommend Cat® diesel engines due to the availability of replacement parts and serviceability via Cat dealerships and certifi ed repair shops in most locations around the globe,” John Jones says.

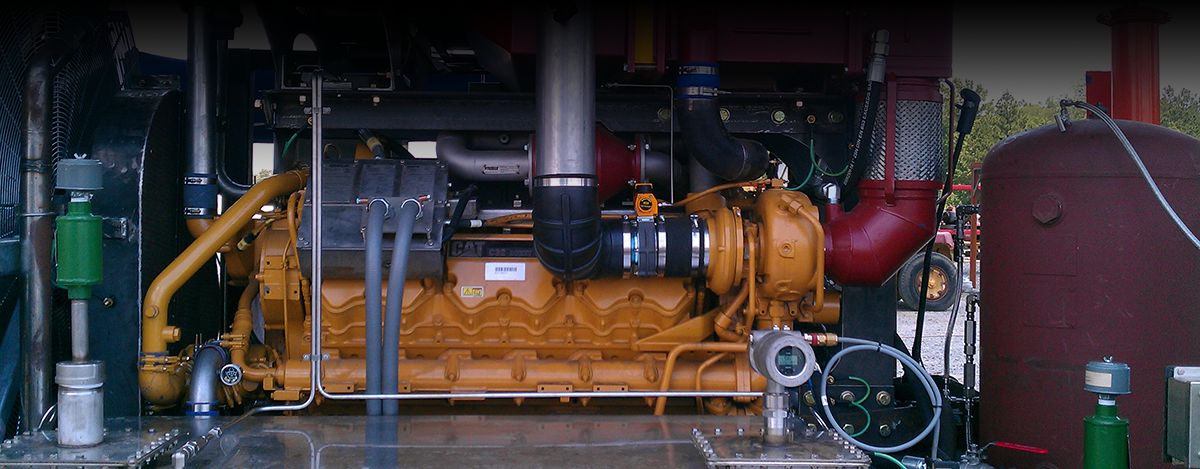

Partners in power. Once a client makes the decision to power a dredge with Cat engines, Custom Dredge Works collaborates with its local Cat dealer, Foley Equipment, to choose the right model for the application. The wide range of Cat industrial power engine options available — along with solutions for varying emissions strategies — makes it easy for the company to give dredge owners exactly what they need. Most larger dredges feature C27 or C32 industrial engines, with smaller C9s or C13s providing supplemental power. So far, the most Cat engines used on a single dredge is four: two C32s plus a C9 and a C7.1 marine generator set.

Built to last. Dealer service and support are major reasons Custom Dredge Works prefers Cat power but so is longevity. The company describes its dredges as “built like a tank,” and when properly maintained, their lifespan can reach up to 40 years. The engines powering them need to stand up to tough conditions and work reliably day in and day out. With Caterpillar’s global dealer network, the company knows dredge owners will have the support they need to maintain optimum uptime and get the job done no matter the location.

"WE RECOMMEND CAT® DIESEL ENGINES DUE TO THE AVAILABILITY OF REPLACEMENT PARTS AND SERVICEABILITY VIA CAT DEALERSHIPS."

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more -

Diamond Products CC5049DC saw - Cat® C2.2 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more

Cat® Industrial Engine Support

Your Cat dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION