Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Shear Force

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- ŽĎAS mobile scrap shear models CNS 400 K and CNS 730 earned gold medals at Central Europe’s International Engineering Fair for their innovative horizontal tool-holding slide-cutting technique.

- Both models cut more scrap of all types per hour than other products and requires only one operator to remove cut scrap from the shear, simplifying operation and minimizing operating costs.

- ŽĎAS offers scrap shears with both diesel and electric power to meet different customers’ requirements. For those who prefer diesel, the company relies on Cat® industrial engines — the C4.4 for the CNS 400 K and the C7.1 for the CNS 730.

- Since Cat engines are regarded as reliable and high quality to ŽĎAS customers, the choice to go with Cat industrial engines was an obvious one.

- With scrapyard customers located around the globe, ŽĎAS relies on the Cat dealer network to keep the CNS 400 K and CNS 730 up and running. Regular service of mobile scrap shears is essential and having these products as part of a Cat powered fleet offers a big advantage come maintenance time with savings on service time and expenses.

Cat® Engine Overview

Cat® C4.4

- The Cat® C4.4 Industrial Diesel Engine is offered in ratings up to 200 hp (150 kW) and peak torque 825 Nm (609 lb-ft) which meet U.S. EPA Tier 4 Final, EU Stage V emission standards.

- A modular and compact core on the Cat C4.4 makes installing the engine on any number of machine applications a relative breeze. And when downsizing from five-liter platforms, OEMs can see a 20% reduction in length, 5% reduction in height and 40% reduction in weight of the engine, significantly reducing installation costs.

- With a 15% increase in power density and 10% increase in torque when compared to its predecessor engine, the compact design of the Cat C4.4 reduces heat loss for more efficient engine output, helping operators conquer even the toughest tasks with relative ease.

- When compared to similar 6-cylinder platforms, the C4.4 saves more than 18% in fluid consumption and is specially balanced to be its most effective, every day.

- Built-in clean emissions modules keep the Cat C4.4 performing at its peak while also keeping the air around the work site cleaner.

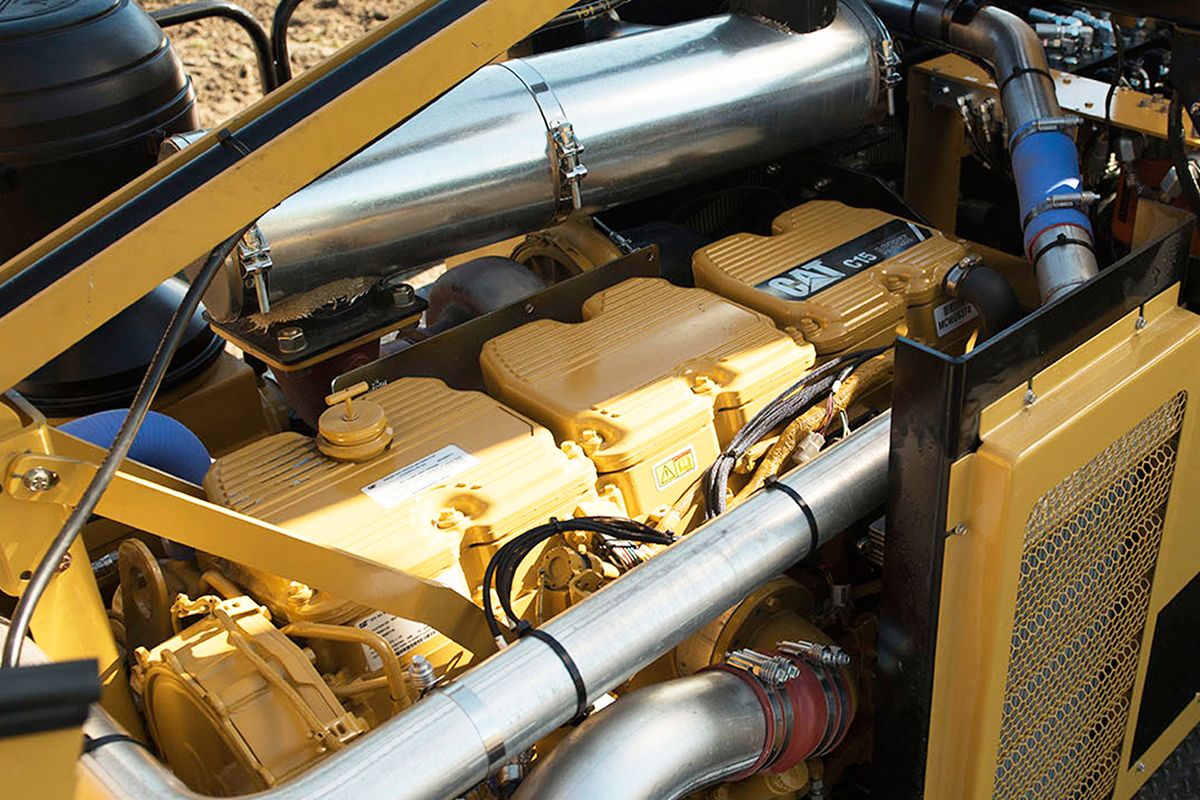

Cat® C7.1

- The Cat® C7.1 industrial engine is offered in power ratings up to 320 hp (239 kW) and peak torque 1268 Nm (935 lb-ft) allowing for downsizing while still getting more responsiveness and productivity than ever before.

- Highly-efficient fuel and turbocharging systems are specially configured to meet a wide range of machine operating cycles while also reducing fuel consumption, up to 20% when downsizing from a larger engine platform.

- With technologically-advanced fuel-injection and SCR systems, the C7.1 reduces the need for DEF consumption, so overall costs remain low.

- The newest thermal management systems and catalysts mean your aftertreatment is fit for the life of your engine.

- When you've got options, you can keep design and installation costs low. The C7.1 has a wide range of configurable options including one that's fit for your machine application.

Compare Models

-

- Maximum Power

- 134 HP

- 100 kW

- Maximum Torque

- 406 lb-ft @ 1500 rpm

- 550 Nm @ 1500 rpm

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

- U.S. EPA & CARB Tier 4 Final, EU Stage V

C3.6

Learn More -

- Maximum Power

- 320 HP

- 240 kW

- Maximum Torque

- 935 lb-ft @ 1400 rpm

- 1268 Nm @ 1400 rpm

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

- U.S. EPA & CARB Tier 4 Final, EU Stage V

C7.1

Learn More -

- Maximum Power

- 456 HP

- 340 kW

- Maximum Torque

- 1540 lb-ft @ 1400 rpm

- 2088 Nm @ 1400 rpm

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

C9.3B

Learn More

POWER PROFILE

ON TOP OF THE SCRAP HEAP

Scrapyard operators face numerous challenges when it comes to processing waste. First, it comes in a variety of forms — metal scrap, cupola scrap, non-ferrous metals, plastics, window profiles and more — requiring equipment that can handle everything from bulky materials to glass. Second, these materials aren’t always all in one place, so processors must be easy to move from location to location. And third, the scrap just keeps coming, meaning equipment needs to work quickly and reliably with minimal maintenance to stay on the job.

ŽĎAS mobile scrap shears check all of these boxes. In fact, the CNS 400 K (introduced in 2000) and the CNS 730 (introduced in 2009) earned gold medals at Central Europe’s International Engineering Fair for their innovative horizontal tool-holding slide-cutting technique. Both models cut more scrap of all types per hour — up to 12 tons for the CNS 400 K and up to 20 tons for the CNS 730 — than other products. And each requires just one operator to remove cut scrap from the shear, simplifying operation and minimizing costs. The two models’ mobile design also is preferred by many scrapyards, since it takes just minutes to move the shears via a hooklift or flatbed trailer to wherever scrap occurs.

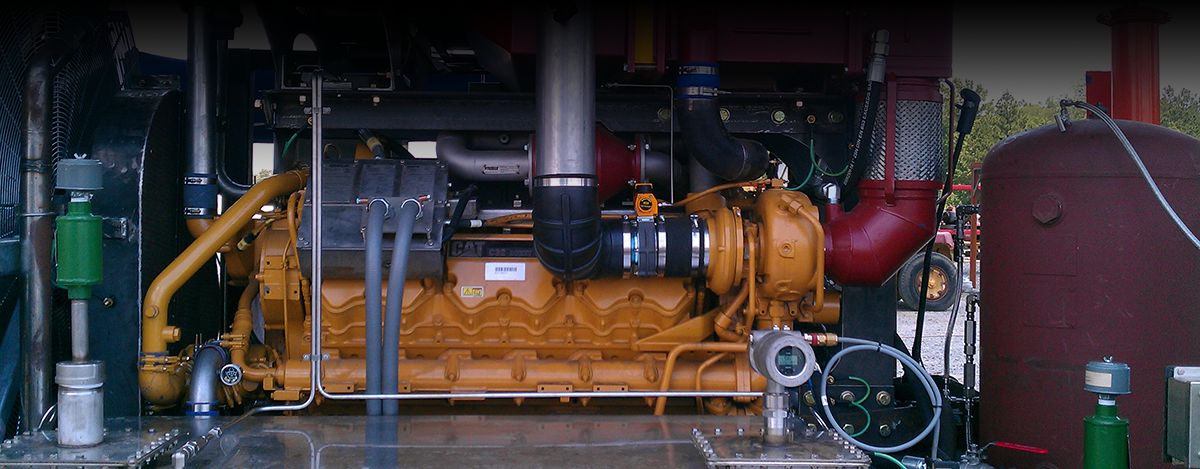

ŽĎAS offers scrap shears with both diesel and electric power to meet different customers’ requirements. For those who prefer diesel, the company relies on Cat® industrial engines — the C4.4 for the CNS 400 K and the C7.1 for the CNS 730.

A CUT ABOVE THE REST

Long service life is critical for waste processing equipment, considering the challenging environments in which it works. ŽĎAS prides itself on the robust construction of its mobile scrap shears — the CNS 400 K and CNS 730 are built to handle as much force as traditional stationary shears. The engines powering them need to be just as tough, and ŽĎAS experimented with a number of brands before landing on a winner.

Tried and tested. Prior to 2012, various engine manufacturers supplied diesel power for the CNS 400 K and CNS 730 scrap shears. That year, the company launched a competition to choose a preferred supplier, and after evaluating engine parameters and after-sale support, Cat industrial engines rose to the top.

“Caterpillar is a renowned brand worldwide, and our customers regard Cat engines as reliable and high quality,” says Zdeňka Hoblová, commercial manager of ŽĎAS’s engineering division.

One reliable design worldwide. With that decision made, ŽĎAS worked closely with Cat dealer Zeppelin to select and integrate the C4.4 and C7.1 into the CNS 400 K and CNS 730, respectively. Nearly a decade later, the company has no regrets. In addition to dependable, low-maintenance performance, the C4.4 and C7.1 use the same engine core to meet different emissions regulations. That means ŽĎAS can use the same main components in the scrap shears it exports worldwide, saving time and money on design and manufacturing.

Service to support an entire fleet. With scrapyard customers located around the globe, ŽĎAS relies on the Cat dealer network to keep the CNS 400 K and CNS 730 up and running. Regular service of mobile scrap shears is essential and having these products as part of a Cat powered fleet offers a big advantage come maintenance time. “Having Cat engines implemented not only in our shears but also in other equipment operating in scrapyards helps our customers save on service time and expenses,” Hoblová says.

“HAVING CAT® ENGINES implemented not only in our shears but also in other equipment operating in scrapyards helps our customers save on service time and expenses.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat® dealer network.

-

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more -

Wolfe Heavy Equipment Trenchers - Cat® C15 and C18 Engines

Learn more -

W.K. Dahms Mfg. Ltd. Stone Slinger - Cat® C4.4 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

Texas Pump Systems Customizable Pump Packages - Cat® C32 Engine

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Rotochopper B-66L Grinder - Cat® C27 Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Paling Transporter - Cat® C13B Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

Orchard-Rite LTD Inc. Monoboom & Bullet Tree Shaker - Cat® C4.4 Engine

Learn more -

Morooka USA MST2200VDR and MST3000VD - Cat® C7.1 Engine

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

JBS Track-Pack Silage Bagger - Cat® C15 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Eagle Crusher UltraMax® 1200-CC Crushing Plant - Cat® C9.3B Engine

Learn more -

Diamond Products CC5049DC saw - Cat® C2.2 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more -

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION