Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Pumping Up The Innovation

Product Overview

Cat Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- When Texas Pump Systems needed to build pump packages for use in explosive atmospheres, they relied on Caterpillar’s hazardous-area certified engine by pairing it with their own custom-control systems, monitoring, gauges and so on.

- Twenty years ago, Caterpillar saw the need for engine compliance with an explosive- atmosphere design, inspiring changes like adding exhaust gas coolers to keep surface temperatures down to 200 degrees and creating a safe work environment which is key to keeping employees at work and productive.

- TPS was able to dramatically increase pump horsepower from 700 to 1300 by using the Cat® C32 industrial power unit.

- The global Cat dealer network provides added value for customers by supplying accessible, unparalleled parts and service including 24/7 online parts ordering access.

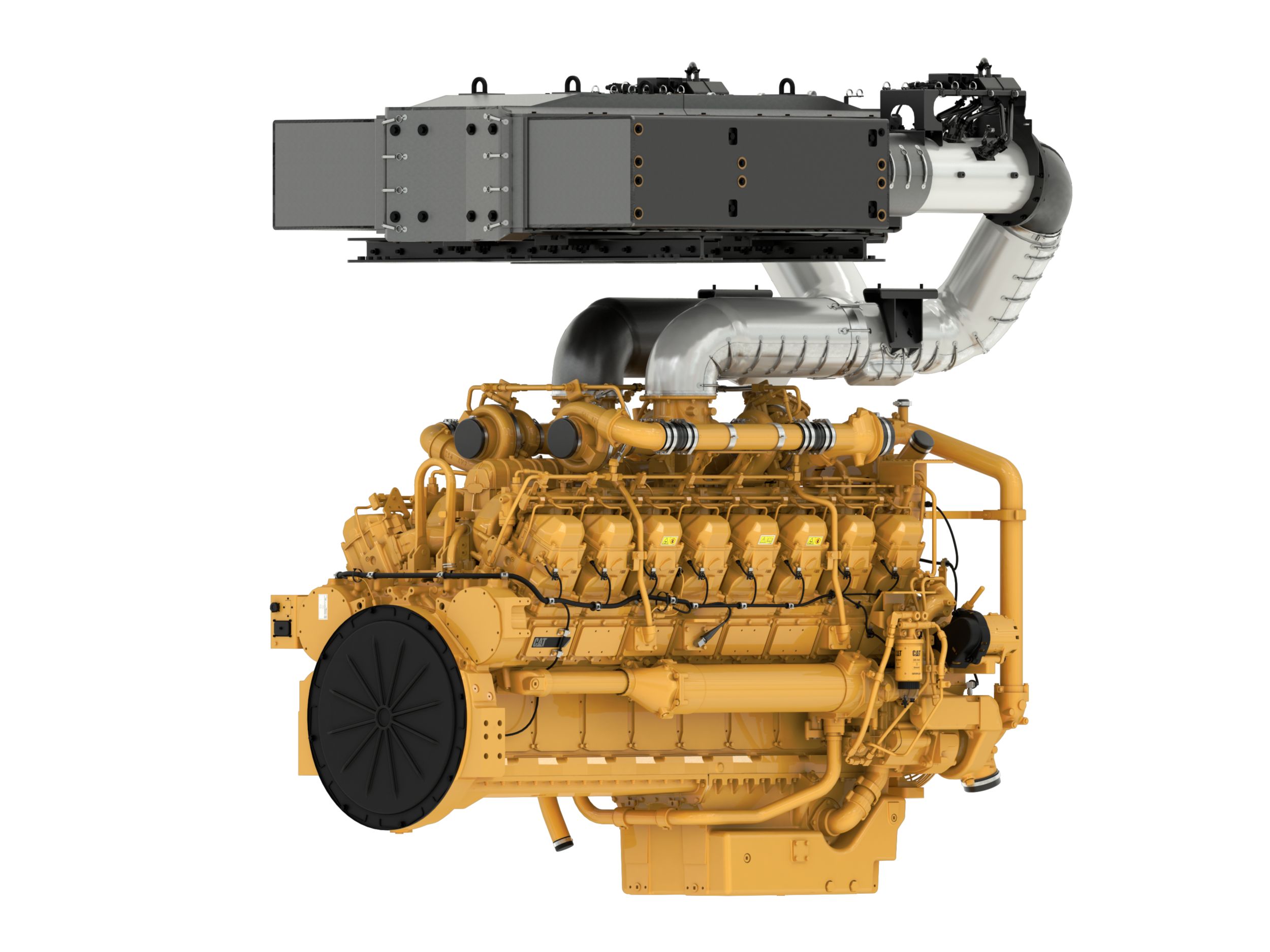

Cat® Engine Overview

- The Cat C32 industrial engine is offered in power ranges up to 1200 hp (895 kW) and peak torque 5500 Nm (4056 lb-ft) and allows for platform downsizing while maintaining reliability and durability.

- The C32 engine is ideal for tough industrial and construction applications such as dredges, chippers, grinders, emergency water pumps and rock drills among other applications requiring continuous peak performance under the most demanding conditions.

- The key to success for any machine is avoiding downtime as much as possible. Thanks to the DEF-free, dual-can DOC with transparent regeneration offered by the 32 engine, operators can stay focused on being productive for the long haul.

- When it comes to making the engine installation process smoother for Original Equipent Manufacturere (OEMs), look to the C32 engine. Using innovative technology solutions, the C32 was created to eliminate the need for thermal management and Diesel Exhaust Fluid (DEF), reducing the size of the overall engine package. And thanks to flexible aftertreatment mounting options, installing such a large engine just got a lot less complicated.

- Optimized to meet some of the most demanding operating cycles of just about any machine, the DEF-free Cat C32 helps owners and operators save on operating costs while also remaining maintenance-free for the engine's lifetime.

Compare Models

-

- Maximum Power

- 1050 HP

- 783 kW

- Maximum Torque

- 3448 lb-ft @ 1200 rpm

- 4674 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C27

Learn More -

- Maximum Power

- 1200 HP

- 895 kW

- Maximum Torque

- 4056 lb-ft @ 1200 rpm

- 5499 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C32

Learn More -

- Maximum Power

- 2100 HP

- 1566 kW

- Maximum Torque

- 8275 lb-ft @ 1200 rpm

- 11220 Nm @ 1200 rpm

- Emissions

- U.S. EPA Tier 4 Final, EU Stage V

- U.S. EPA Tier 4 Final, EU Stage V

3516E

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

Customizable Pump Packages

LOCATION:

Stephenville, TX

SCOPE OF ENGINE USE:

Cat® C32 Industrial Disel Engine

DEALER:

Avoiding Fireworks

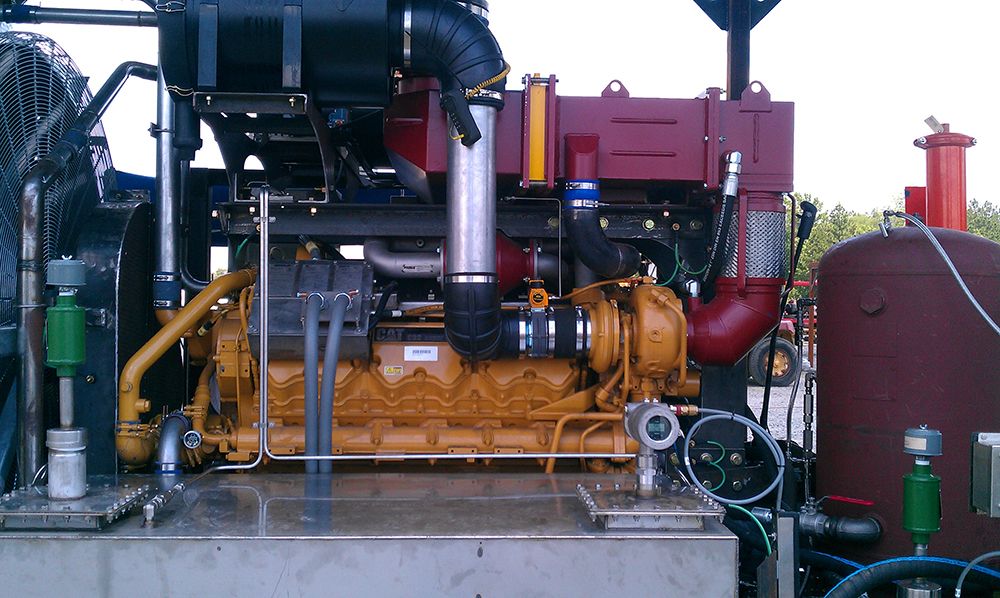

Safety first. We all learn that on day one, regardless of where we work. But imagine if you worked on an offshore oil rig. When you’re miles out at sea, safety is absolutely everything. Texas Pump Systems creates customized pump packages for clients around the world—including oil companies that need pumps for floating production and storage facilities. This equipment is used for “pigging,” which entails pumping fluid from the seabed into vessels that hold a couple million barrels of crude oil. Obviously, it makes for quite an explosive atmosphere.

“Using diesel engines in that particular application causes for a lot of headache, because you can imagine with these engines sitting on two million barrels of crude oil—one spark will make a pretty good firecracker,” explains Ernst Vanderlaan, General Manager of Texas Pump Systems. Not surprisingly, achieving a perfect combination of safety and performance was a pretty sizable hurdle to overcome. Twenty years ago, requirements for engine compliance when it came to usage around hazardous explosive materials was lax at best. But Caterpillar saw the need for explosive-atmosphere design and got to work. Innovative engine design inspired changes like adding exhaust gas coolers to keep surface temperatures down to 200 degrees.

So when Texas Pump Systems got the call to build pump packages for use in explosive atmospheres, they were able to rely on Caterpillar’s hazardous-area certified engine to be used at the heart of their assembly. By pairing that with their own custom-control systems, monitoring, gauges and so on, Texas Pump Systems was able to deliver top-of-the-line packages that would not only get the crucial job done, but also keep all those hard-working folks (and their well-earned sea legs) completely safe.

The Need For Speed

Texas Pump Systems was founded in 2014 in Stephenville, Texas. When it comes to crafting pump packages, they’re far from an assembly line. The company specializes in customizing one-off products that meet the ultra-specific needs of clients—for everything from steel mills to drilling operations to water disposal (and a whole lot in between). “I really don’t think there’s anybody else that does engine-driven packages like we do,” Vanderlaan says. “Every application requires a different configuration, so every pump system requires a different configuration. If you package the stuff right, it’s going to last a long, long time.”

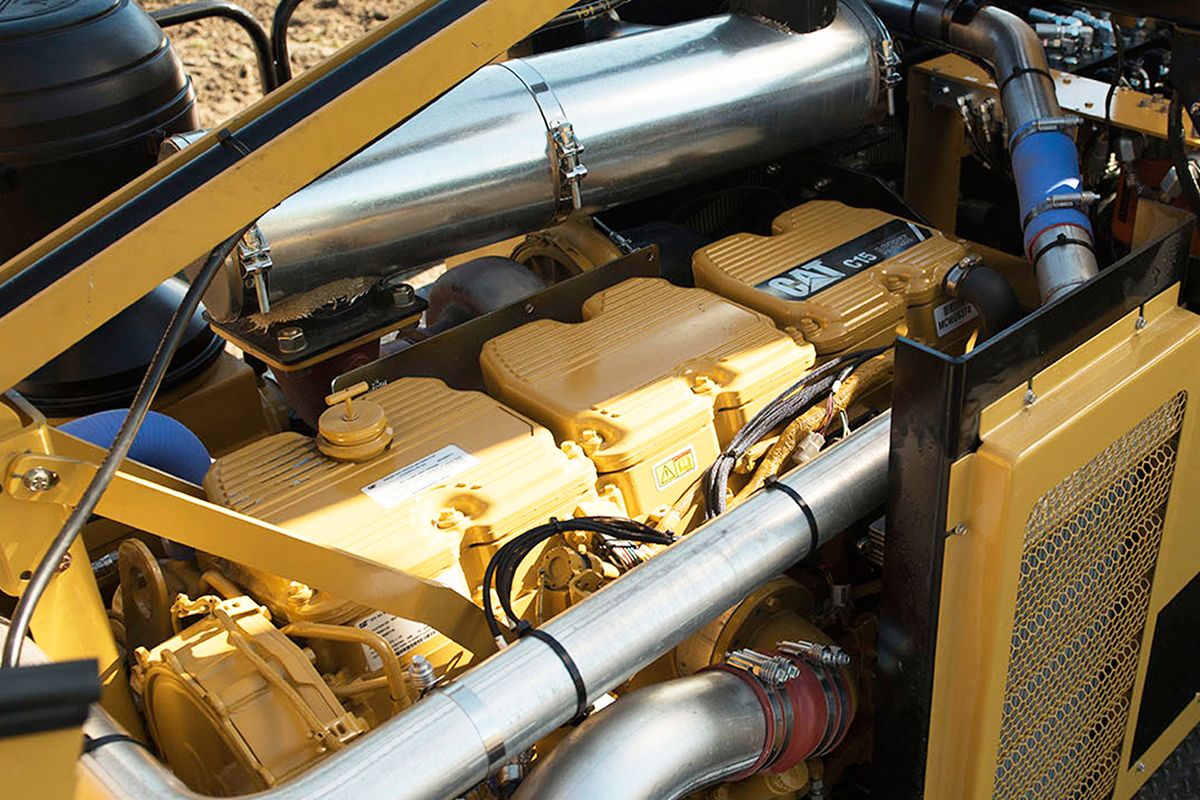

That affinity for creative thinking came in quite handy when Texas Pump Systems’ existing customer Graco Oilfield Services came with a new request. Graco has been a pioneer in the higher horsepower market, being the first ones to use 700 hp pump packages in their well servicing. Come 2019, they were looking to dramatically up their game to 1,300 hp application, which nobody had done before. The envelope-pushers at Texas Pump Systems made it happen with a Cat® C32 industrial power unit (IPU) at the heart of the package. The designers chose the C32 specifically because of its reduced size and weight—not to mention its extreme reliability and affordability.

The big challenge was to fit an automatic transmission behind the engine and keep the cost down for the customer. Vanderlaan’s team solved the issue by using new C32 engines paired with rebuilt transmissions and high-pressure pumps to minimize the expense. So not only did Graco save money, but their new packages allow them to complete jobs much faster than the lower horsepower machines—and also achieve a deeper horizontal lateral while they’re at it (up to 5,000 feet with the latest pumps). Talk about a win/win for everyone.

“I work a little different. I think one-offs are challenging—they’re fun,” says Vanderlaan. And with these pump-packaging puzzles to constantly solve, the Texas Pump Systems team works closely with their Caterpillar dealer, Holt Texas, to brainstorm completely outside-the-proverbial-box unique solutions and answer the (literally) powerful questions. That way clients know that their customized packages are one-of-a-kind and more than ready to work. “When Holt says Caterpillar is a family, they truly mean it,” Vanderlaan explains. “It takes a village, and they’ve always been such a resource—even friends—for us.”

“I DON’T EVEN SEE CATERPILLAR AS A VENDOR ANYMORE - THEY’RE PRETTY MUCH PART OF OUR COMPANY. WE’RE FAMILY.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

Allmand Maxi-Heat - Cat® C1.1 Engine

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

Custom Dredge Works Custom Dredges - Cat® C32 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

Diamond Products CC5049DC saw - Cat® C2.2 Engine

Learn more -

Ferris IS6200 Mower - Cat® C1.7 Engine

Learn more -

Gorman-Rupp Pump PAH8A60 and PAH8A65 - C9.3B Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

IMW Industries - Cat® G3406 Gas Engine

Learn more -

Orchard-Rite LTD Inc. Wind Machine - Cat® C7.1 and C4.4 Engines

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

SB Manufacturing, Inc. Superior Broom SM74 and DT74 Sweepers - Cat® C3.4 Engine

Learn more -

Sullair Portable Air Compressors - Cat® C4.4 Engine

Learn more -

Sullivan-Palatek D900HAF Compressor - Cat® C7.1 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Therm Dynamics TD425 Flameless Heater - Cat® C2.2 Engine

Learn more -

VMAC Global Technology - Cat® C1.1 Engine

Learn more -

Vermeer PD5 Pile Driver - Cat® C2.2 Engine

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more -

Zeal Motor Inc. Fat Truck 2.8 C - Cat® C2.2 Engine

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION