Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Power in the Trenches

Product Overview

Cat® Engine Overview

Read profile

Gallery

Related Profiles

PRODUCT OVERVIEW

- With the challenge of identifying an engine solution for its wheel trenchers, drainage plows and dewatering trenchers that would meet Tier 4 Final emission standards without sacrificing equipment performance, Wolfe needed support. Cat® dealer Tomomont stepped in and a new relationship was formed.

- Toromont brought the Wolfe and Caterpillar design teams together — and the two groups collaborated on a solution that is delivering optimal results despite the tight engine compartment space.

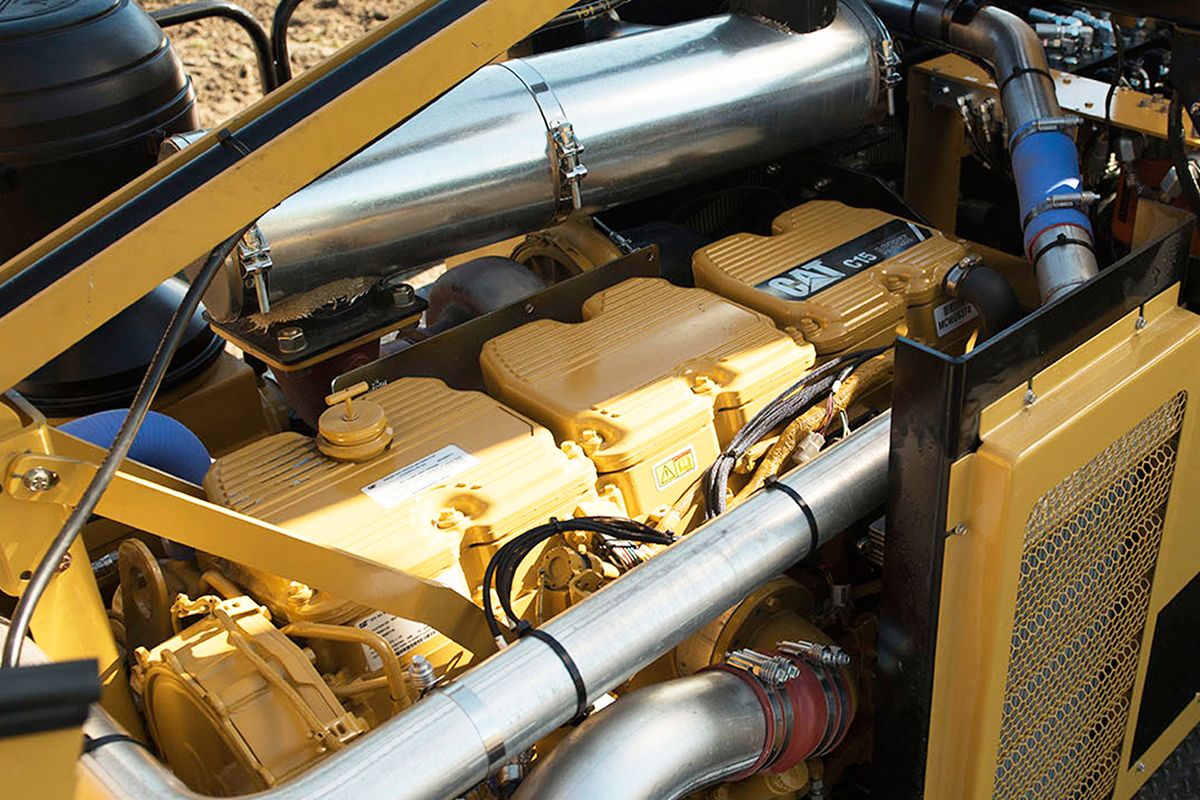

- Cat C15 and C18 engines, providing horsepower ranging from 475 hp to 630 hp, not only enable Wolfe’s trenching equipment to meet Tier 4 Final emission standards, but also help the company ensure those products hold grade in even the toughest conditions.

- Another selling point in the selection process — Cat engines have a strong brand reputation and name recognition with customers.

- Worldwide support with the Cat dealer network was another factor in Caterpillar's favor, and Wolfe's equipment is global and requires reliable global support.

Cat® Engine Overview

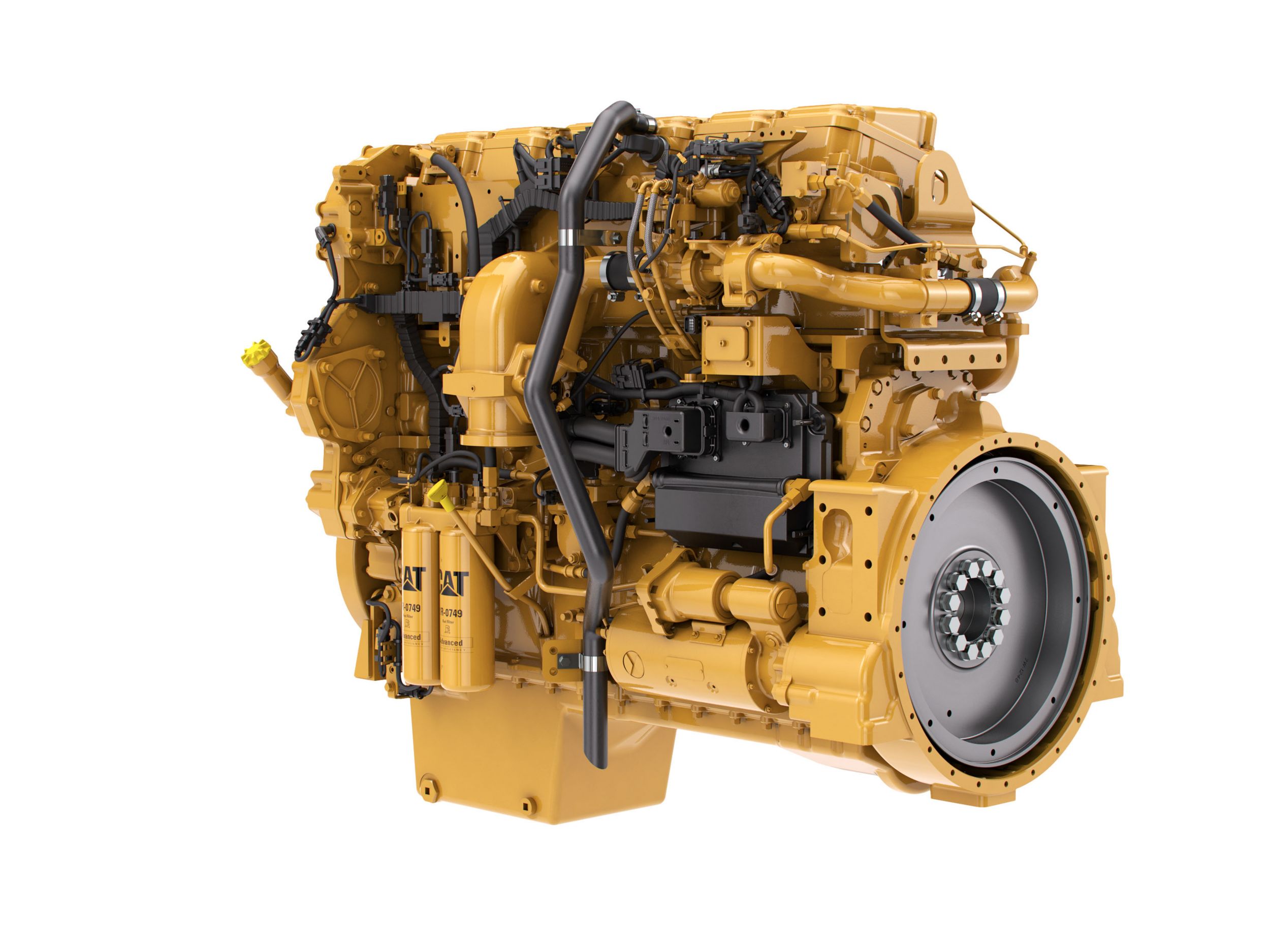

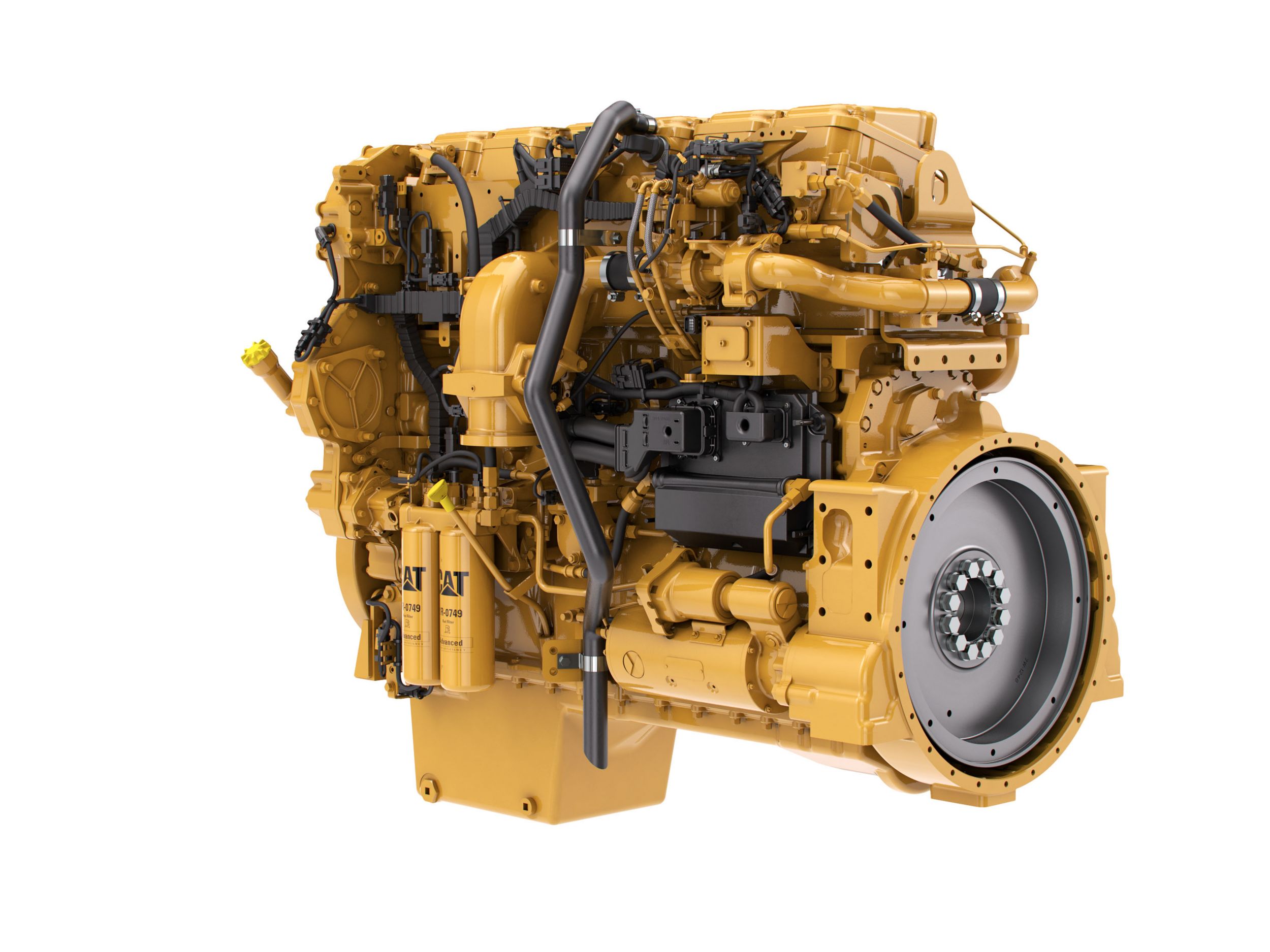

Cat C15

- The Cat® C15 industrial diesel engine is offered in power ratings up to 580 hp (433 kW) and peak torque 2655 Nm (1959 lb-ft) with transparent regeneration technology built into every Cat C15, operators can continue to be productive without ever having to wait.

- The C15 engine features a 5,000-hour DPF service interval and DEF capacity of 93.7 liters, giving machine operators the opportunity to spend more time on the job site and less time in the shop.

- The Cat C15 offers a fully-configurable engine across a wide range of power nodes, flexible aftertreatment mounting options and the ability to install the engine's IPU straight from the factory, so OEMs can keep installation time and costs to a minimum.

- Aftertreatment can either be shipped loose and installed remotely for maximum flexibility or factory installed and engine mounted for easier installation. The engine was developed to optimize fluid consumption based on a wide range of operating cycles and applications.

- Global engine is dual certified U.S. EPA Tier 4 Final and EU Stage V and has similar ratings for markets where Tier 4 Final or Stage V certification are not required. And with 500-hour maintenance intervals, owners can keep parts and service costs low.

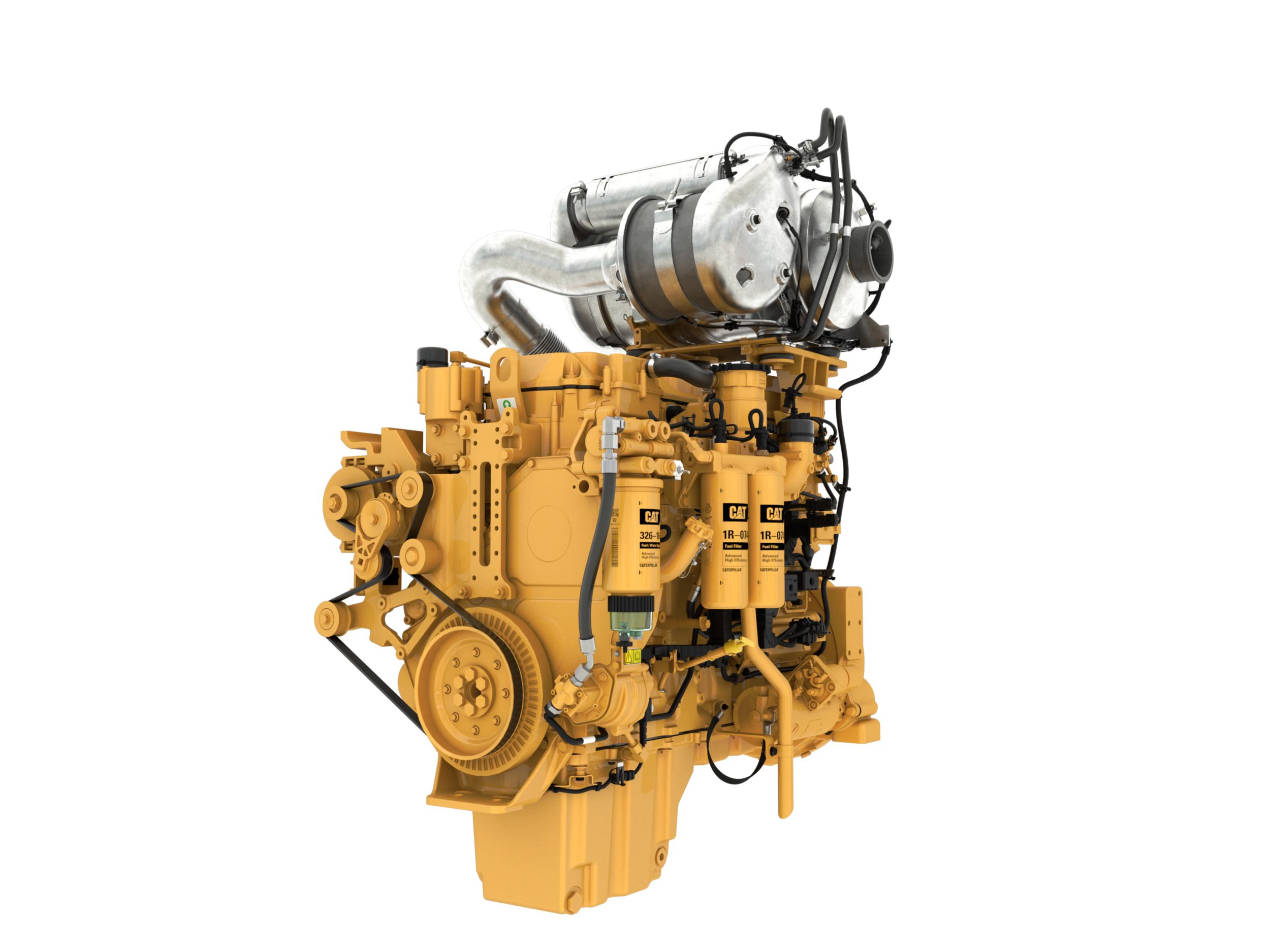

Cat C18

- 6-cylinder, 18.1 liter industrial engine is offered in power ratings up to 800 hp (597 kW) and peak torque 3710 Nm (2736 lb-ft) and provides a compact, flexible and quiet engine system that's ideal for your equipment application.

- The Cat C18 is designed for optimal power and torque with a proven aftertreatment reducing the cost of installation and ownership while providing maximum uptime.

- Common core engine shared with other Cat industrial engine models offers common machine interfaces and controls architecture. Allows customers to develop commonality in products, parts and service among equipment in their fleets.

- Engine is designed for low parts and labor maintenance requirements reducing overall cost of ownership.

- The modular engine platform offered by the C18 engine complements a global customer base while providing factory solutions to reduce equipment manufacturers' design and installation costs.

Compare Models

-

- Maximum Power

- 577 HP

- 430 kW

- Maximum Torque

- 1943 lb-ft @ 1400 rpm

- 2634 Nm @ 1400 rpm

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

- EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV

C13B

Learn More -

- Maximum Power

- 580 HP

- 433 kW

- Maximum Torque

- 1958 lb-ft @ 1400 rpm

- 2655 Nm @ 1400 rpm

- Emissions

- U.S. EPA Tier 4 Final

- U.S. EPA Tier 4 Final

C15

Learn More -

- Maximum Power

- 800 HP

- 597 kW

- Maximum Torque

- 2736 lb-ft @ 1300 rpm

- 3710 Nm @ 1300 rpm

- Emissions

- EU Stage V

- EU Stage V

C18

Learn More

POWER PROFILE

CUSTOMER:

PRODUCT:

Trenchers

LOCATION:

Ontario, Canada

SCOPE OF ENGINE USE:

Cat® C15 and C18 Tier 4 Final,

EU Stage V Industrial Engines

CAT DEALER:

INNOVATION HAS LONG DRIVEN WOLFE HEAVY EQUIPMENT’S SUCCESS

Founded in 1953, the company delivered its first prototype self-propelled drainage plow in the late 1970s, and for the last two decades has manufactured completely hydrostatically driven track and rubber-tired equipment. In 2012, Veeke Inc. purchased Wolfe, moved it into a modern manufacturing facility and implemented new systems and processes to enhance the overall customer experience.

Thanks to this ongoing focus on anticipating and responding to customer needs with equipment updates and technological advances, Wolfe has been able to greatly reduce machine downtime and operating costs while increasing output in agricultural and municipal drainage, oil and gas pipeline and dewatering applications across North America.

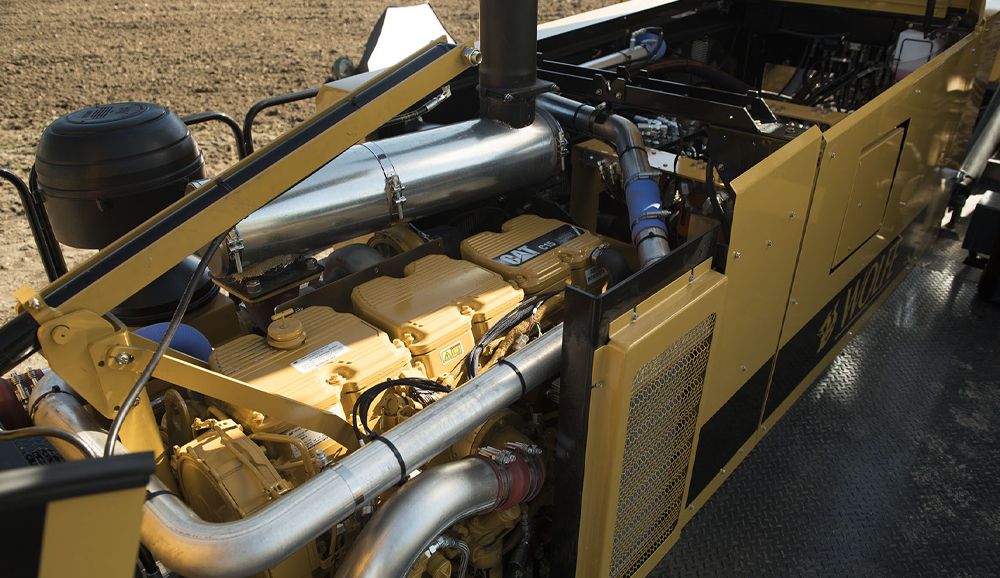

Continuing to deliver those benefits while meeting U.S. EPA Tier 4 Final emission standards presented a challenge, however. Space constraints made it difficult for Wolfe to identify an engine solution for its wheel trenchers, drainage plows and dewatering trenchers that would reduce emissions without sacrificing equipment performance. To tackle the problem, Cat dealer Toromont brought the Wolfe and Caterpillar design teams together — and the two groups ultimately collaborated on a solution that is delivering optimal results despite the tight space.

Cat® C15 and C18 engines, providing horsepower ranging from 475 hp (354 kW) to 630 hp (470 kW), not only enable Wolfe’s trenching equipment to meet U.S. EPA Tier 4 Final emission standards, but also help the company ensure those products hold grade even in the toughest conditions. The combination of selective catalytic reduction (SCR) technology and diesel particulate filter (DPF) systems delivers clean power without compromising durability or uptime.

Paul Veeke, a project manager for Wolfe, has been impressed with the durability, longevity, fuel efficiency and total cost of ownership of Cat industrial engines. Worldwide support is another factor in Caterpillar’s favor, particularly given the wide reach of Wolfe’s equipment. “We’ve never had to try to sell someone on our equipment using a Cat engine,” Veeke says.

Wolfe doesn’t need to be sold on the value of Cat dealer support, either. According to Veeke, Toromont doesn’t just provide the service he expects from the Cat brand — the dealership goes above and beyond to help Wolfe succeed.

In addition to bringing the Wolfe and Caterpillar design teams together to solve the U.S. EPA Tier 4 Final emission standards challenge, for example, Toromont also supplied a sample U.S. EPA Tier 4 Final engine for Wolfe’s 2017 CONEXPO-CON/AGG booth. “Toromont has been excellent to work with,” Veeke says. “They do what they say they will.”

“WE’VE NEVER HAD TO TRY TO SELL SOMEONE ON OUR EQUIPMENT USING A CAT® ENGINE.”

POWER PROFILE IMAGE GALLERY

Related Power Profiles

See what other Cat® industrial engine customers have to say about our engines and related products, and the support they receive from the Cat dealer network.

-

W.K. Dahms Mfg. Ltd. Stone Slinger - Cat® C4.4 Engine

Learn more -

Mobile Track Solutions MTS 3630T and the 3630W - Cat® C18 Engine

Learn more -

Morooka USA MST2200VDR and MST3000VD - Cat® C7.1 Engine

Learn more -

Eagle Crusher UltraMax® 1200-CC Crushing Plant - Cat® C9.3B Engine

Learn more -

CW Mill Equipment Co. HogZilla Monster Grinders - Cat® C32 Engine

Learn more -

Pronar MRW 2.85 Shredder - Cat® C9.3B Engine

Learn more -

Hurley Land Clearing Bandit 4680 Grinder - Cat® C32 Engine

Learn more -

T-MAR Industries Log Champ 550 & 650 - Cat® C9.3B and C15 Engines

Learn more -

Bandit Industries, Inc. Beast 2460XP Horizontal Grinder - Cat® C13B Engine

Learn more -

Bandit Industries, Inc. Intimidator 18XP & 19XPC - C4.4 and C7.1 Engines

Learn more -

Paling Transporter - Cat® C13B Engine

Learn more -

City of San Antonio/HogZilla Tub Grinder - Cat® C32 Engine

Learn more -

Infrastructure Contractors/MTS 3630T Construction Tractor - Cat® C18 Engine

Learn more -

CAS® Slinger - Cat® C7.1 Engine

Learn more -

DOK-ING MV-10 mine clearing system - Cat® C18 Engine

Learn more -

JBS Track-Pack Silage Bagger - Cat® C15 Engine

Learn more -

ZDAS CNS 400 K & CNS 730 mobile scrap shears - C4.4 and C7.1 Engines

Learn more -

Rotochopper B-66L Grinder - Cat® C27 Engine

Learn more -

Komptech Crambo - Cat® Industrial Engines

Learn more -

Tesmec 1075 Chainsaw Trencher - Cat® C9.3B Engine

Learn more -

McCloskey International Screeners - Cat® Industrial Engines

Learn more -

Puck Enterprises Pumps - Cat® C9.3B and C13B Engines

Learn more -

Atlas Copco DrillAir XRVS 1550 - Cat® C18 Engine

Learn more

Cat® Industrial Engine Support

Your Cat® dealer is your go-to resource for everything from installation support to troubleshooting to in-the-field service. With 171 dealers serving 192 countries, the expert assistance you need is always close at hand.

TIPS AND INFORMATION