Sign In

Welcome! Sign In to personalize your Cat.com experience

If you already have an existing account with another Cat App, you can use the same account to sign in here

Register Now

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

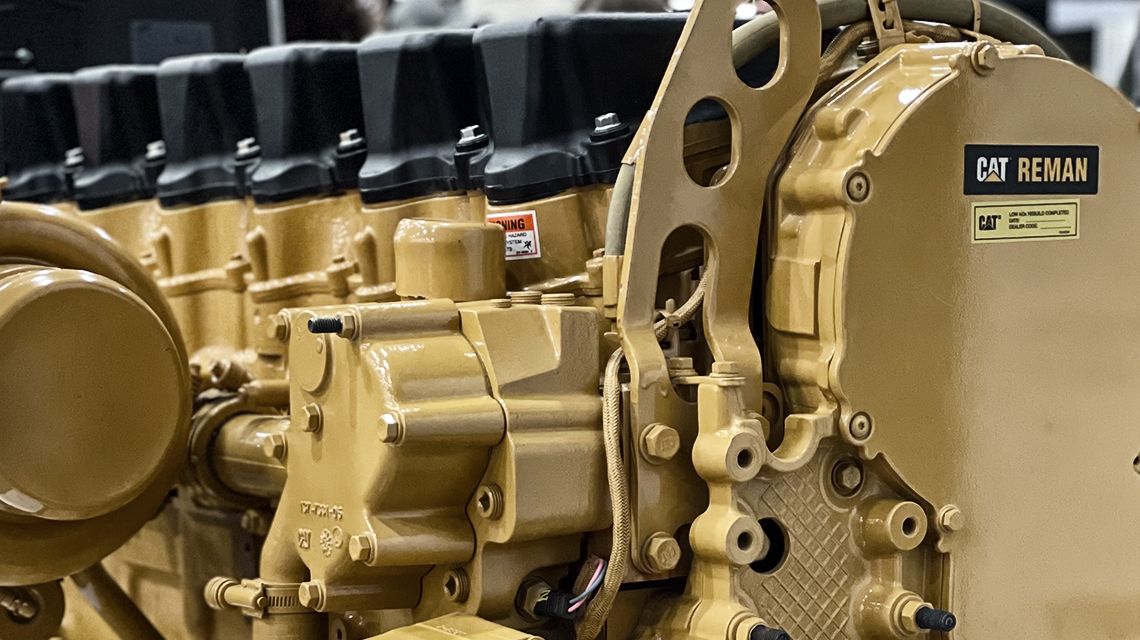

THE CAT® REMAN PROCESS

The Core of Cat Reman

By Cat Reman | Posted: October 13, 2022

Core Return Drives Cat® Reman Value

The Cat® Reman process starts with the concept of “core return.” When you bring a qualifying used part — a “core” — back to your Cat dealer, you can receive a core deposit back. Then, that core is sent for remanufacturing at a Cat Reman facility. Let’s discover how core return works and how it delivers value to Cat customers.

Reviving Cat Reman Parts

When a machine component reaches the end of its service life, what happens to it? Sometimes, it may be rebuilt by an equipment dealer or a specialized build shop. Other times, it may just go to a scrap yard or landfill. In 1973, however, Caterpillar came up with a third solution — comprehensive remanufacturing that goes beyond a simple rebuild.

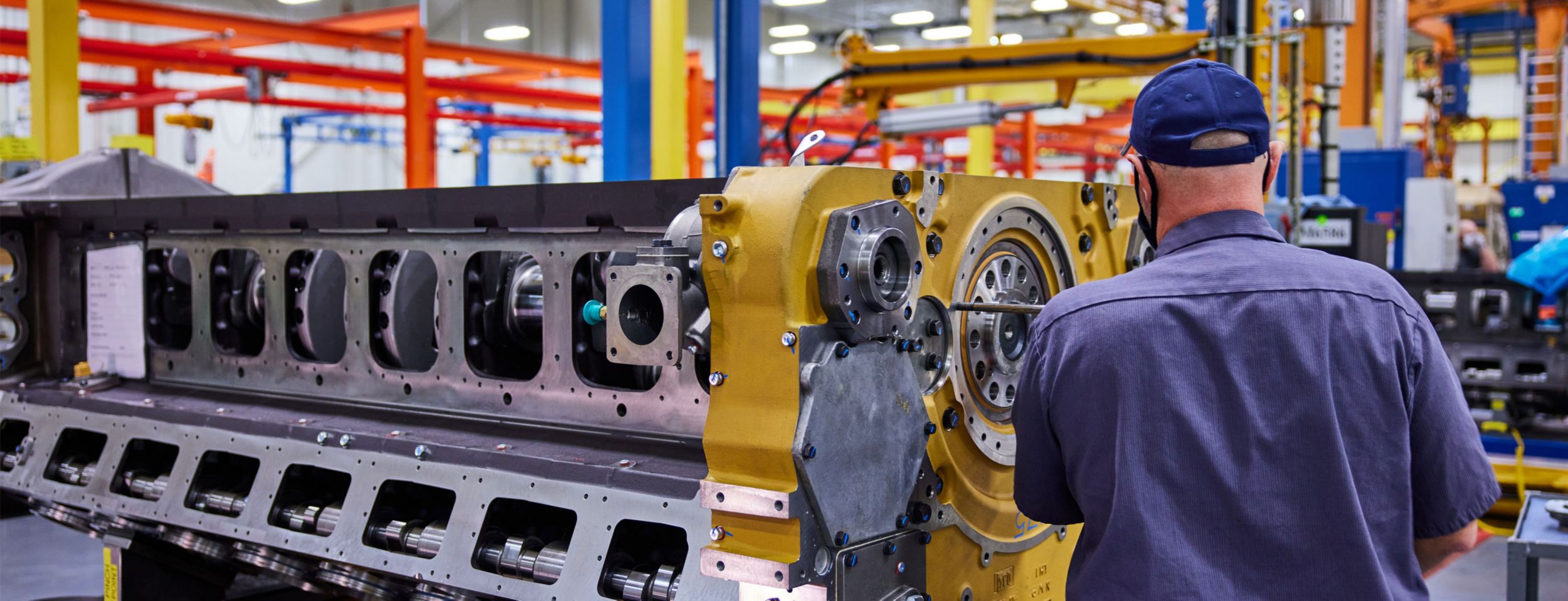

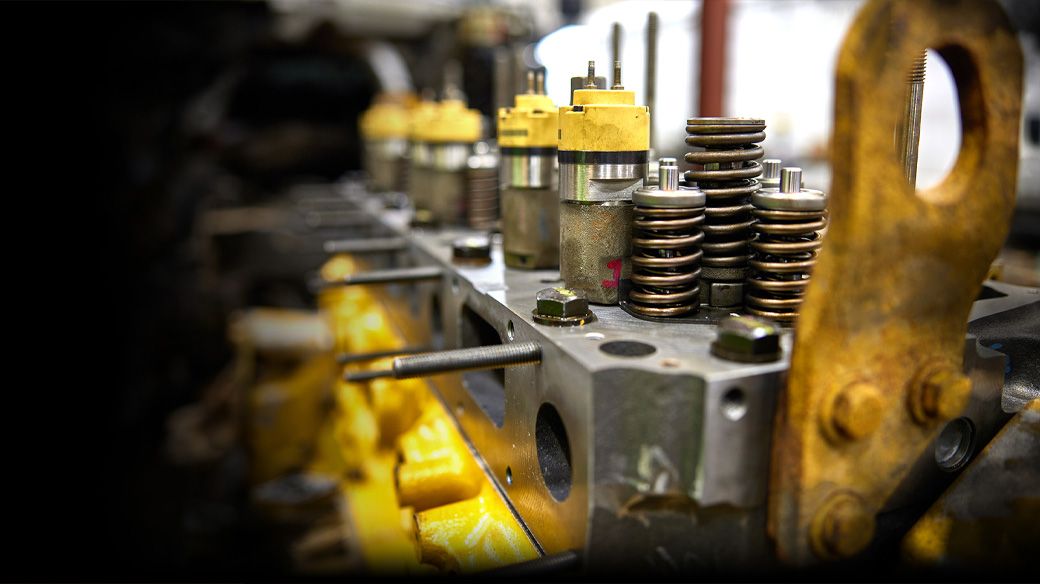

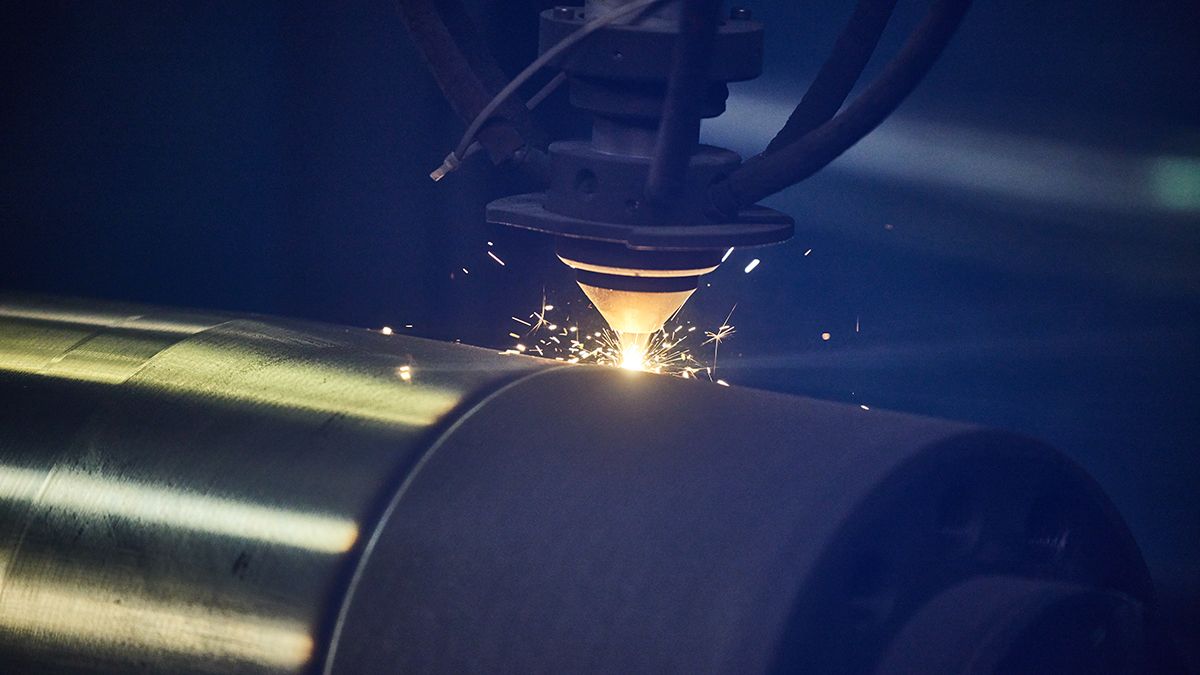

The Cat Reman process strips an end-of-life component down to its smallest piece parts, inspects and cleans everything to a microscopic level and remanufactures usable components to like new condition. From there, the part is remanufactured (not just reassembled) using the same factory specs as a new part, including any new technologies or product updates. Then, it gets reintroduced to the market as one of over 8,000 types of Cat Reman products.

And the entire process starts with the idea of “core return.”

Cat Reman relies on customers to return end-of-life components to their Cat dealer in exchange for a credit on a replacement Cat Reman product.

“The lifeblood of our business is really around that core coming back from our customers,” says Trent Tippey, Construction Industry Commercial Manager for Cat Reman. “That way we can leverage our processes in order to return it back to like new.”

Jeff Gutzwiller, Cat Reman Product Manager for Engines and Engine Components, says core return is key to the value of Cat Reman because cores in good condition can be remanufactured for less money and using fewer resources than the manufacture of a new part from scratch.

He explains, “That's very important to us because A) it's more sustainable, it's the right thing for the environment and B) it keeps things out of landfills. It also reduces the energy… we use in our remanufacturing process. When we get that core back… if it's a core piece of iron — like a casting or a forging — we're just taking it back and we're salvaging it and putting a relatively low amount of energy and work into that product to bring it back to that like new condition… We’re saving energy and saving raw materials by reusing that initial forging or casting or component. That saves a tremendous amount of energy.”

Returning a Core

Obviously, a good core is more valuable than one that needs a lot of salvage work, so meeting Cat Reman core acceptance criteria (CAC) will net a customer a bigger credit toward a replacement part.

While there are specific core requirements for different types of parts (see sidebar), the general criteria are easy to understand. A good, useable core:

- Is fully assembled and complete

- Is not visibly cracked, broken or welded

- Displays no non-operational damage such as mishandling, excessive rust, corrosion or pitting

- Has an acceptable Cat part number still visible

Essentially, says Kathy Monson, Cat Reman Commercial Manager, “We want the core in an ‘as removed’ condition… Any attempt to salvage that core will lead to a rejection… Standard operating damage, things that you would normally see in the operational use of a product, generally [is] accepted.”’

Dale Nordman, Parts Manager for Cat dealer Butler Machinery in Fargo, North Dakota, says core rejections happen less often these days. “In the past, we probably had more concerns over core criteria. Caterpillar [has] made that easier, as time has gone on as far as inspections, processes and what is considered a good core, partial core or an old core… In the end, [customers] know… what their end result is going to be.”

Cat Reman Engineering Team Lead Kegan Luick notes that ongoing developments in the remanufacturing and parts salvage process have helped to relax the core return criteria. “The Salvage Development team is constantly working to address more and more defects and failure modes of the cores so that we can maintain the reusability and costs of our remanufacturing process.”

The Remanufacturing Process Begins

When a customer brings a part in for core exchange, the Cat dealer performs an on-the-spot core inspection and provides an exchange price. If the dealer has a replacement part in stock, the exchange can happen right away. If not, a Cat Reman product can be delivered from one of several facilities around the world.

According to Renea Miller, Section Manager for the Cat Reman facility in Corinth, Mississippi, about 95% of the cores returned worldwide come through the Corinth facility.

From there, she says, the race is on. “When that core piece comes in, that core has to be turned around in 48 hours. The clock starts when that core is actually scanned off of [a] truck. Then, once it's inspected, it either goes to our warehouse facilities and [is] used internally [at the Corinth facility] or it's distributed to other facilities.”

Those facilities then remanufacture the cores to like new quality standards and return them to the Cat Reman product line.

Jeff Gutzwiller sums up the remanufacturing process: “We get your core back. We completely disassemble it, clean it and then use state-of-the-art salvage operations to bring it back to like new performance. And then it is assembled in a Caterpillar manufacturing environment, using the Cat quality management system. And then it goes back out to the field with like new performance backed up by… the same warranty as new.”

Streamlining the Cat Supply Chain

“The big advantages of using the Cat Reman product [are],” notes Gutzwiller, ”you're getting your product from the same people that designed it and validated it new — from the same people that have the access to all that intellectual property and know-how.”

Cat Reman Strategy Manager David Andres says core return helps customers get the critical parts and components they need in a timely manner by letting them play a critical role in streamlining the Cat supply chain. “When you use Cat Reman and return the core, you're relieving the supply base constraints and the pressure, and you're generally helping Caterpillar serve you recursively and in the future.”

Trent Tippey adds, “We look at that core as an opportunity … Getting that core back — getting the opportunity to bring it back to like new, meeting the same quality tests as it was when it was new — is something that not every remanufacturing entity on the globe can do. And we take a lot of great pride in being able to do that for our customers.”

Check out the range and variety of available Cat Reman parts.

Cat Reman

The thought leaders and subject matter experts involved in the design, development, distribution and marketing of Caterpillar’s remanufactured, like new products.

Related Stories

-

Improving efficiency underground: Seven top areas to evaluate

Underground hard rock mines present some of the most challenging conditions for mining operations. Despite these challenges, underground miners are always on the lookout for ways to improve loading and haulage performance to lower cost per ton.

Learn More -

Keeping things clean: 10 things you can do to reap the benefits of contamination control

The steps mines can take to control contamination range from the straightforward — such as good housekeeping — to the less common, such as particle counting. The basic procedures focus on clean facilities, clean components, clean processes and clean fluids.

Learn More -

9 ways to ensure haul roads are an asset — not a liability

Well-designed and maintained haul roads a have a significant impact on productivity and costs. When haul roads are kept in top condition, trucks run faster and more safely, cycle times improve and more ore is produced. Good road conditions also reduce truck maintenance, lower fuel costs and reduce tire damage. There are several key activities that will ensure haul roads are kept in top condition.

Learn More -

Wheel dozers help mines increase efficiency of production fleet

Wheel dozers combine the production capabilities of track-type tractors with the mobility and versatility of wheel loaders. Cat® Wheel Dozers are based on Cat Wheel Loaders — designed for mining applications, with structures and a powertrain designed for dozing.

Learn More -

Looking for ways to control costs? Financial solutions can enable efficiency gains

When it comes to hauling ore, conventional wisdom would indicate that buying a bigger truck will result in greater productivity. But the experts at Caterpillar point out that the benefits larger trucks bring to the operation may be offset by negative impacts on other areas. It’s important to consider the complete mining enterprise when evaluating a change in truck size.

Learn More -

Mining truck considerations: Is bigger always better?

When it comes to hauling ore, conventional wisdom would indicate that buying a bigger truck will result in greater productivity. While it’s true that more is being hauled with every truckload, there are a number of considerations that may lead to the conclusion that that bigger isn’t necessarily better.

Learn More -

Caterpillar’s Customized Operator Training Courses Helped Morgan Corp.

A customized operator training course from Caterpillar is helping Morgan Corp. increase profits, safety & productivity one jobsite at a time.

Learn More -

On Her Own, But Not Alone

Samantha Ruttura is fourth generation in the construction industry and a long-time Cat customer who had the courage to start her own small construction business.

Learn More -

Career Building Tips for Women in Construction

Get expert advice on how to start a career in construction and thrive in a male-dominated industry. Check out our career building tips for women in construction.

Learn More -

Cat® Mining Truck Named the Coolest Thing Made in Illinois

In 2020, the Cat 797F Mining Truck was named the coolest thing made in the state of Illinois.

Learn More -

Mixed results: How change management impacted implementation of a new rope shovel technology

When a new technology feature was introduced on Cat® 7495 Electric Rope Shovels (ERS) several years ago, it was met with mixed results. Some reported good results while others said the feature was limiting productivity. So why the different outcomes? It came down to how sites rolled out the feature and managed the change.

Learn More -

Tips for implementing change on your mine site

Successful implementation of a technology solution is contingent upon a culture of trust. These change management tips will help keep management and workforce on the same page when it comes to implementing new technologies.

Learn More -

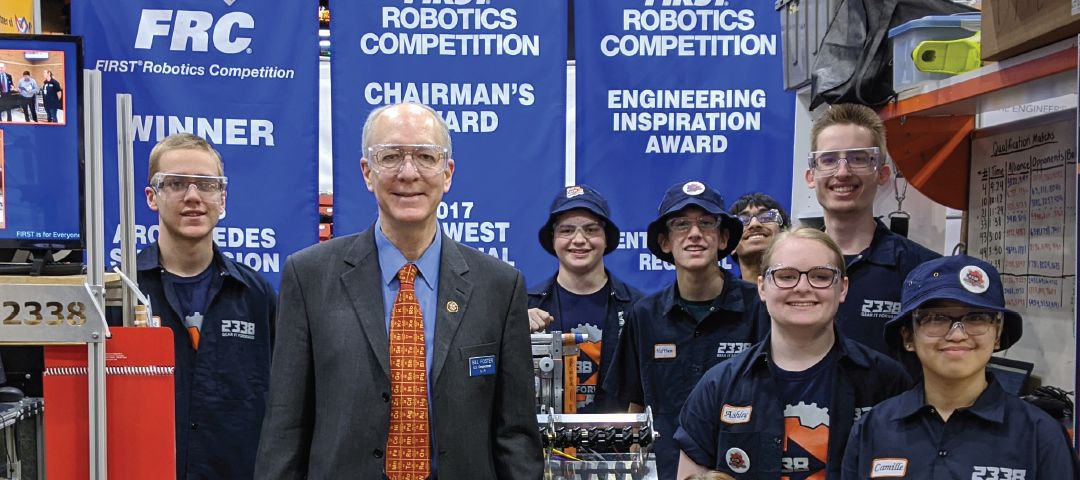

Caterpillar's Support of Students in STEM

FIRST Robotics uses mentor-based programs to build the skills of students in STEM in 100+ countries. See how Caterpillar's FIRST Robotics sponsorship impacts students in STEM.

Learn More -

Paving The Way For Fans

For Donley's Concrete Group, helping to revitalize the Richmond Raceway's infield was a dream come true. With help from the Cat Rental Store, they made the track better for fans.

Learn More -

Managing Mental Health Issues in Construction

Michelle Walker is dedicated to addressing mental health issues in the construction industry. Her goal is to provide workers on any jobsite the resources they need.

Learn More -

Long Term Equipment Hires Reimagined

Since 2007, Axis Hire has helped mining, civil & construction companies across Australia secure their ideal fleets, with a focus on long-term equipment solutions.

Learn More Equipment Maintenance -

Aquifer Recharging in Troubled Wetlands

Longtime Cat customer Phillips and Jordan was part of collaborative effort to build the world’s largest, man-made aquifer system designed to recycle groundwater.

Learn More -

Cat® Equipment Financing Requirements

Our equipment financing requirements aren't complicated. See the four key factors we consider when you apply to take advantage of Cat equipment financing.

Learn More -

Long-Time Dozer Operator

Kenny Nichols, long-time dozer operator and Cat equipment owner, has dedicated his life to doing the work he loves. With 84 years and 110,000 hours behind the controls, he may be the most experienced dozer operator around.

Learn More -

PAC-MAN™ Behind The Scenes with Lance Endres

From designing & selling a console to restoring old arcade games, Lance Endres has always had a passion for video games. So it was a dream come true to be the Art Director for Cat Trial #9: PAC-MAN™.

Learn More -

Caterpillar Holiday Gift Guide 2023

Find gifts for construction workers, outdoor enthusiasts, kids & more in our 2023 gift guide. Check out our 70+ options of toys, clothes, tools and tech.

See Our Lists -

Prioritizing Employee Health and Safety

Jobsite safety should always be a top priority, even beyond the machines. Find out how Cat customers have taken extra precautions to keep their employees healthy during the COVID-19 pandemic.

Learn More -

How Turner Mining Uses Social Media Recruiting

Contract mining will never be the same. See how Turner Mining taps into social media recruiting to make dirt work appealing to hard-to-reach Millennials and Gen Zers.

Learn More Labor Shortage Solutions -

The Legacy of Holt & Best

Benjamin Holt and C.L. Best changed the industry over 100 years ago – first as competitors, and then as the founders of Caterpillar. Their passion for customers and innovation lives on today.

Learn More -

Safe Host Takes a Colourful Approach to Safety

Colour-coded equipment is used to create a safer work environment at a data centre in Switzerland.

Learn More -

Supporting Up-and-Coming Contractors

Starting out in the construction industry can be tough, especially in the Middle East. However, Saudi Arabian Cat® dealer, Zahid Tractor, is changing that.

Learn More -

Clearing the Way for Sustainable Energy Solutions

See how one customer aided in providing sustainable energy solutions to a community by clearing the land for a solar panel farm & using the trees to provide mulch.

Learn More -

How Diverse Hiring Can Help Solve the Construction Labor Shortage

Diverse hiring offers a solution to the construction labor shortage. See how one female contractor’s diverse hiring positively impacted both her business & the community.

Learn More -

Finding Love on the Track: A Motocross Wedding

Construction operator JP spent the morning of his motocross wedding in a Cat Dozer preparing the track where he & Ashleigh first met for their ceremony. Read their story!

Learn More -

Mulching to Reduce Greenhouse Gas Emissions

A method of sustainable waste management is turning landfill waste into mulch. With Cat® powered grinders, cities can reduce greenhouse gas emissions & landfill capacity.

Learn More -

Cat Financial Program Supports Customers During Disasters

Cat Financial’s Customer Care Program offers assistance to eligible customers whether they're impacted by disasters or crises.

Find out how -

Getting the most from electric rope shovel swing racks: Precision design, operating techniques and proper maintenance

Electric rope shovels can load more material — more efficiently and more cost-effectively — than any other loading tool in the mining industry. These highly productive machines rely heavily on the swing rack, which is one of the hardest working pieces of the electric rope shovel.

Learn More -

Providing a turnkey rental solution

In South Dakota’s Black Hills, Cat dealer® Butler Machinery is delivering a power-by-the-hour solution for Coeur Mining’s Wharf gold mine that includes a fleet of machines, maintenance support, and on-site technicians who complement the Wharf workforce.

Learn More -

Developing a Safety Culture at Home

The safest jobsites are those that have a strong safety culture, but what about when those employees go home? Hear from Caterpillar safety expert Justin Ganschow on why employee safety behavior at home matters.

Read Our Safety Culture Q&A -

3D Printing Technology For More Than Machines

Caterpillar partnered with OSF HealthCare to give a patient a fighting chance with a 3D printed liver. See how 3D printing in healthcare can help save lives.

Learn More -

Tips For Preparing a Business Disaster Plan

A natural disaster disrupts everything from your daily schedule to the ability of your business to continue operations. Read our tips for creating plans and preparing for the worst.

Learn More -

Proving the value of a new dozer — and a strong partnership

Mine developer Pelly Construction has chosen Caterpillar and Cat® dealer Finning Canada to fill a critical role — supporting its operations in remote areas like Canada’s Yukon. And when it came time to choose a customer to prove its new D10 Dozer, Caterpillar and Finning chose Pelly.

Learn More -

Benefits of a Cat® Card with Cat Financial

Maximize benefits with the Cat Card from Cat Financial. Explore exclusive perks and flexible financing options for your equipment needs. Elevate your business with smart financial solutions.

SEE THE BENEFITS -

Celebrating 50 Years of Demonstration Training

Celebrate the 50th anniversary of Caterpillar’s demonstration and learning centers with stories about our global facilities and expert demonstration training.

Learn More -

Using a D8R Dozer for Environmental Rehabilitation

Mongolia's largest man-made lake was created using a Cat®D8R dozer as an act of environmental rehabilitation. The man-made lake was once a functional mine - see how it was done!

Learn More -

7 Ways to Prevent Equipment Downtime

Equipment downtime can delay your projects. Read about the top ways to prevent downtime, including the use of equipment monitoring and proper storage steps.

Learn More -

3 Ways A4 Technology Takes A3 to New Levels

With 4,500+ Cat® G3600 engines with ADEM™ A3 (2002-2015) technology at work in gas compression—exceeding 150 million hours of reliable operation—it would be easy to fall victim to an “if it ain’t broke, don’t fix it” mentality. Not at Caterpillar.

Learn More -

Sending a Cat® Rugged Smartphone into Space

When university students wanted to send a phone into space, one Cat licensee knew it would take a tough phone to handle the pressure. See why they chose a Cat S62 Pro.

Learn More -

How to Become an Equipment Operator

Interested in learning how to become an equipment operator? Caterpillar tells you everything you need to know about education, training, and career success.

Learn More Training -

The Blending of Art and Engineering

Caterpillar's Industrial Design team infuses Cat DNA into our products by blending art and engineering. Watch how the team's design process has evolved over the years.

Learn More -

How to Plan Amidst Business Uncertainty

Making decisions under uncertainty is no easy feat for any business. Check out our tips for planning during business uncertainty so you can ensure you're ready for 2021.

Learn More Business Tips -

Viewpoint: Perspectives on Modern Mining from Caterpillar

Produced by Caterpillar Global Mining since 2007, Viewpoint features mines around the world showcasing relevant topics — like safety initiatives, new technologies, best practices in operations and maintenance, sustainability leadership in environmental efforts and much more.

Learn More -

The Secret Sauce of Cat® Reman

Want to know what makes Cat® Reman parts unlike other products on the market? Join members of the Caterpillar team as they detail the ingredients — the affordability, availability and sustainability benefits — that make up the secret sauce of Cat Reman.

SEE WHAT IT’S MADE OF -

4 On-Highway Truck Engine Tips to Save You Fuel and Money

Turn to these truck engine tips to keep your hauler running longer, with one step that could cut cost per hour by 80%.

Learn More -

This Shop Gets Trucks (and Bees) Back on The Road Fast

See how I-70 Truck Center works with Caterpillar to get rigs — including semis hauling honeybees — back on the road fast.

Learn More -

Flood Safety Tips: Before, During and After

If you live in a flood zone, it's critical to know how to prepare for a flood. Discover important flood safety tips, including how to evacuate your home safely.

Learn More -

Road Trip Safety: Steps Before and During Every Trip

Prepare to stay safe on your next road trip. Follow Caterpillar's road trip safety briefing and car safety tips. Learn more.

Learn More -

Mushroom Farming More Efficiently With Cat Machines

Our dealer Bosusan Cat provides mushroom farm Pema Mantar the compact and small Cat wheel loaders they need to improve efficiencies and reduce fuel costs.

Learn More -

Cybersecurity for Businesses: Keeping Safe From Cyber Threats

At Caterpillar, we take a proactive approach to protecting your information while establishing security within our connected solutions. Contact us today.

Learn More -

How to Give a Safety Briefing at Home

A safety briefing is a simple routine that will help you and your family stay safer at home. A good place to start is with our S.A.F.E. 4-step process.

Learn More Safety -

3 Ways to Save with Cat Reman Injectors

Wonder what Cat® Reman injectors can offer your equipment? Explore these three ways that remanufactured injectors from Caterpillar can save you on expenses while optimizing your engine. Get efficiency with proven availability, protection and long-lasting quality.

READ THE ARTICLE -

Why Mental Health Support Matters on Every Jobsite

Mental health in construction often lacks the attention it deserves. Caterpillar teaches the importance of mental health safety on the job site.

Learn More -

Engine Overhaul Tips

Stop downtime before it happens and identify issues before they turn into bigger problems with these engine overhaul tips.

Learn More -

Cat® Reman With New Content

Learn about the like new performance of Cat® Reman engines and long blocks with new content — and what they offer customers.

Learn More -

How to Develop an At-Home Safety Plan

Just as you have a comprehensive safety plan at work, you also need one for your family. Read our steps to create an at-home safety plan.

Learn More Safety -

Damaged Core or Not a Cat Core? No Problem.

Damaged Core or Not a Cat Core? No Problem. Your core doesn't need to be in perfect condition to receive credit. Here's an overview of acceptable core you can return. Come back to Cat Reman.

Learn More -

Million Miler Mark Droubay

Meet Mark Droubay, owner of Double D Distribution in Utah, with 10 Cat® truck engines past the million-mile mark.

Learn More -

Cat® Reman Customer Profile

The operations team at Eutaw Construction describes how high-quality Cat® Reman products help them cost-effectively maintain a large heavy civil equipment fleet.

READ THE ARTICLE -

How Does an Autonomous Truck See?

Caterpillar autonomy expert Jagath Samaraweera explains how Cat autonomous trucks "see" what's coming using an advanced perception system.

Learn More -

How to Talk To Kids About Safety

Talking to kids about personal safety might feel overwhelming, but using the right approach will ensure they learn the valuable safety lessons they need.

Learn More Safety -

Moving Material on the Pennsylvania Turnpike

Find out why three different contractors relied on Cat® 6015B Hydraulic Shovels to handle excavating duties on a major construction project on the Pennsylvania Turnpike.

Learn More -

Cat® Reman Leadership

What drives the affordability, availability and sustainable processes of Cat® Reman? Get to know the leadership team that helps determine the goals, initiatives and selling points of the Cat Reman product line.

READ THE ARTICLE -

Hybrid Energy Solutions from Caterpillar Support B2Gold's Sustainability Goals

Learn about why B2Gold Corp. selected Caterpillar and Cat® dealer Barloworld to supply 7 MW of solar power at the Otjikoto Mine in the Republic of Namibia.

Learn More -

New Simulator Partnership Provides a Comprehensive Training Solution

Caterpillar has complemented its own offerings by entering into an agreement with ThoroughTec® Simulation, one of the world’s leading training technology organizations.

Learn More -

Roadside Emergency Kits for Your Car: An Essential Checklist

Wondering how to make a roadside emergency kit? This checklist has the essentials you'll need to keep you safe on the road.

Learn More -

Cat® Reman Dealer Showcase

Cat Reman offers low cost and high quality options with same-as-new warranty coverage to give Cat dealer Thompson Machinery a competitive edge –– delivering outstanding parts availability and fast turnaround to customers.

READ THE ARTICLE -

The Circular Economy | Cat® Reman & Sustainability

How the Cat® Reman process provides sustainability benefits, reduces waste and adds value for customers.

Get The Full Story -

Best-in-Class Truck Design Leads to a Better Bottom Line

We offer trucks in a wide variety of sizes to meet every need and application. But one thing all Cat trucks have in common is the philosophy we follow in their design.

Learn More -

Building a Construction Sensory Bin

Creating a construction sensory bin using your kid’s favorite construction toys can help them develop fine motor skills, stimulate their senses, and more

Learn More -

Breathing New Life Into Old Machines: 10 Steps

Today’s miners continually look for ways to make every dollar count. One way they reduce costs associated with their mining machines is through equipment rebuild programs.

Learn More -

How to Clean Heavy Equipment

Heavy equipment gets dirty. Knowing how to clean heavy equipment properly, including tips on pressure-washing for heavy equipment, will keep machines in top shape.

Learn How Equipment Maintenance -

5 Shocking Products Made From Oil And Gas

Whether helping us go about our daily lives or aiding us in exploring the next frontier, these 5 products are proof that there is more to the oil and gas industry than meets the eye.

Learn More -

Safely and Efficiently Assembling One of the World's Largest Machines

See how Cat® dealer Ferreryros delivered and assembled a 7495 Electric Rope Shovel without a single reportable accident

Learn More -

How Much Does It Cost to Rebuild Your Cat® Machine?

Cat® Certified Rebuilds cost significantly less than new equipment. Get your equipment back to work in about 8-12 weeks with the help of Cat Financial.

FIND OUT HOW -

How Cat® Supports Chad Berger Bucking Bulls

Chad Berger, 12-time PBR Stock Contractor of the Year, is the proud owner of several Cat® machines that he uses to help keep his bull bucking business at its best.

Learn More Staying Profitable -

Oilfield Songs from Top Country Artists

Sit back and let this top country songs inspired by the oilfield take you on a musical journey from the coal mines of the Appalachia to the basins in the West.

Learn More -

Partnering to Increase Rope Shovel Productivity

See how a new dipper design helped Alpha Coal improve the pass match of the 7495 Electric Rope Shovel.

Learn More -

Million Miler Melvin Douglas II

Meet Melvin Douglas II, owner of One Job Leads to Another, Inc., who's passed one million miles with his Cat® C-16 engine.

Learn More -

A Broad Range of Repair Options

Whether you need to replace a part, overhaul your engine or find another repair option, Caterpillar has you covered.

Learn More -

Disaster Preparedness Shopping List Must-Haves

Our disaster preparedness shopping list has 23 ideas that go beyond the basics, including a grocery list of non-perishable foods that can still provide a balanced diet.

Learn More -

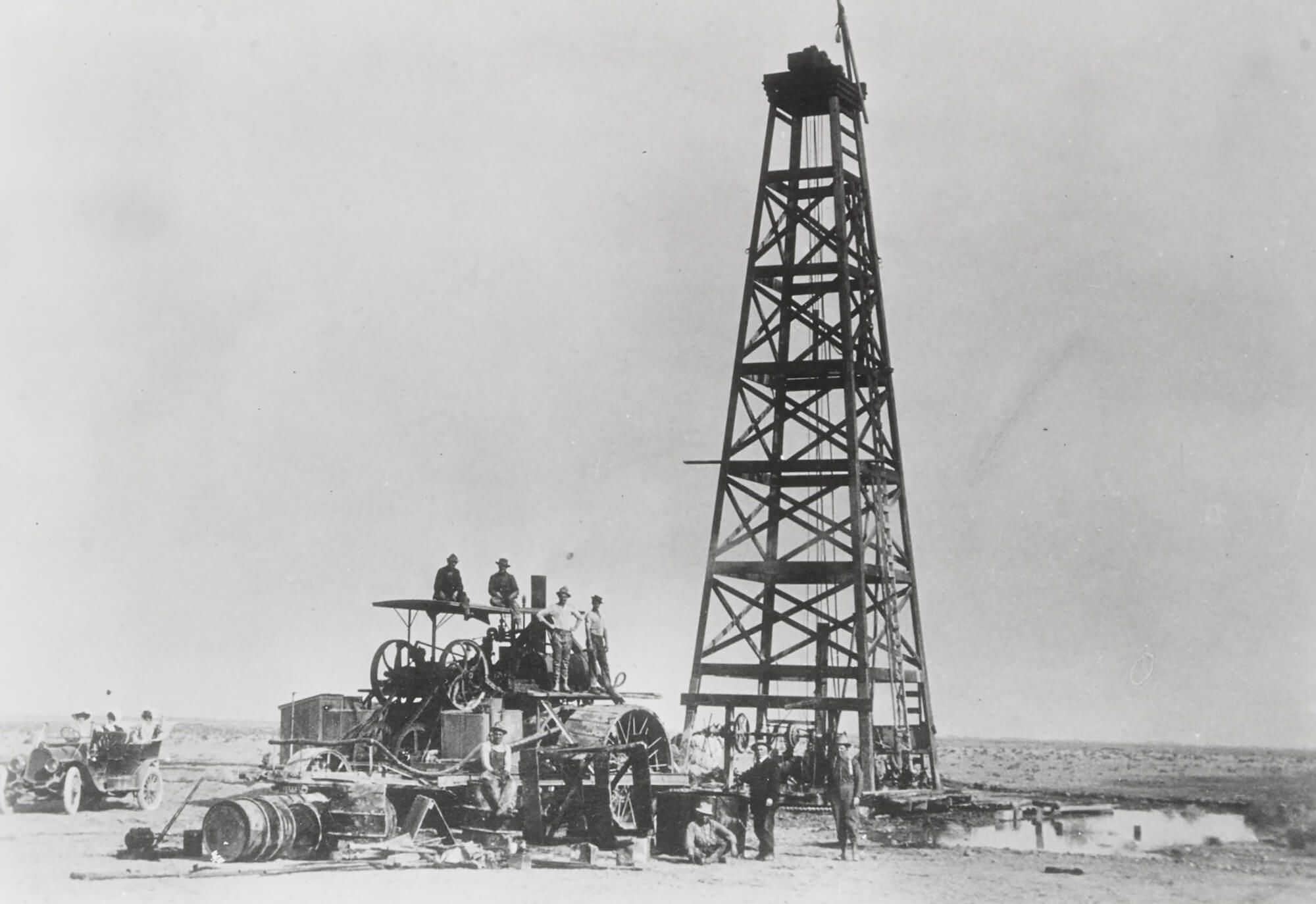

Cat® Reman History

Since 1973, Cat® Reman parts and components have brought affordable, available and sustainably produced parts to customers’ equipment. Learn about the events, people and places that made Cat Reman possible.

READ THE ARTICLE -

Leveraging Clean Diesel Engines in Underground Applications

Learn more about how Cat hard rock underground mining customers take advantage of clean diesel solutions to improve emissions.

Learn More -

Top Reasons to Visit the 2022 Monaco Yacht Show

A Mediterranean sunset shimmering upon the waters of the French Riviera. Superyachts lining the harbor as far as the eye can. The latest innovations in Caterpillar Marine technology. No, this isn’t the premise of the next double-O spy movie. It’s the Monaco Yacht Show!

Learn More -

Optimizing Operations & Minimizing Impact

Learn more about the many ways in which Caterpillar has reaffirmed its commitment to helping our customers meet their sustainability goals.

Learn More -

Building the Flat Track Speedway with American Flat Track

Caterpillar is a proud sponsor of American Flat Track, so when New Hampshire Motor Speedway was ready to build its first flat track in 25 years, we made it happen.

Learn More -

Confessions of an Oil and Gas Intern - Part I

Read this collection of stories from some of our Oil and Gas Interns to get a behind-the-scenes look at what possibilities Caterpillar has to offer for the next generation. Maybe you, or someone you know, could be in their shoes next Summer!

Learn More -

6 Caterpillar Collectors and Their Collections

Read our Q&A with six Caterpillar collectors to learn how they have started their collections of antique Caterpillar machinery, equipment models and collectibles.

Read more Brand Loyalty -

Four Ways to Get the Most From Your bauma Munich Experience

Bauma 2022 is almost here and regardless if this is your first or fiftieth time attending the show, these tips will help you get the most from your time at bauma.

Learn more -

Should You Repair, Rebuild or Replace Cat® Equipment?

A machine rebuild offers distinct advantages over repair — and is less expensive than replacement. Let’s review the pros and cons of repair, rebuild and replace.

COMPARE YOUR OPTIONS -

Manufacturing Is So Nice, We Do It Twice

To celebrate Manufacturing month, we’re exploring the people and places that help bring those engines inside these machines to life... sometimes even twice!

Learn more -

Confessions of an Oil and Gas Intern - Part II

Read this collection of stories from some of our Oil and Gas Interns to get a behind-the-scenes look at what possibilities Caterpillar has to offer for the next generation. Maybe you, or someone you know, could be in their shoes next Summer!

Learn More -

Going the Extra Mile to Take Advantage of the Booming Mining Industry in Remote Mongolia

See how Caterpillar and Cat dealer Barloworld Mongolia are helping a customer take advantage of the booming mining industry in Mongolia.

Learn More -

Building a New Dam in the Alps

Everything about the Kühtai Dam Project is huge. From its estimated €1bn cost, to its location, 2,200 meters up in the Austrian Alps, to the number and size of Cat® machines they’re using.

Learn More -

Day in the Life: Wayne Zemke

The Oil & Gas industry is always changing, and the market changes with it. Here at the Caterpillar Oil & Gas division, we rely on our market intelligence team to be our eyes and ears, to help us do the work so that we can help our customers do theirs. Enter Wayne Zemke!

Learn More -

0% Equipment Financing - Too Good to Be True?

Is 0% financing a good deal for you, the buyer? Learn how zero interest loans work, and how to save money on your next Cat® equipment purchase with our guide to equipment financing.

Learn More -

The Design of Cat® Reman

The design process for Cat® Reman products is a continuous cycle of collaboration, performance and efficiency. In this article, we’ll explore this cycle and discover how the teams behind Cat Reman and new Cat parts work side by side to deliver quality parts solutions for your equipment.

READ THE ARTICLE -

Coal Mine on the Leading Edge of Drilling Autonomy

Learn more about how Mount Pleasant coal mine is serving as a test bed for the future of drilling autonomy.

Learn More -

Options for Acquiring Heavy Equipment

Unlock smart choices for heavy equipment acquisition. Explore financing, leasing, renting and other fleet-building strategies for optimal business efficiency.

EXPLORE YOUR OPTIONS -

Outstanding Women of the Oil & Gas Industry: Part I

Outstanding Women of the Oil & Gas Industry: Part I

Learn More -

Cat Trial 13 – Behind The Scenes

Cat Trial 13: Goodnight, Goodnight Construction Site brings a beloved construction picture book to life. Take a peek behind the scenes to see how we made it happen.

Learn More -

Trucking Is Life: Cody White | Cat® On-Highway Truck Engines

Meet Cody White, one of the many Cat® truck engine owners who believe "trucking is life."

Get The Full Story -

Rising Repair Costs Got You Down? Protect Yourself With Extended Service Coverage (ESC)

Explore the protection that Cat® Extended Service Coverage (ESC) can offer your Cat truck engine and get an estimate today!

Learn More -

How to Finance Engine Overhaul Costs

What’s the best way to manage engine overhaul cost? Explore your financing options.

FIND OUT MORE -

World-First Autonomous Drilling Solution Implemented in Australian Coal Operation

Learn more about how mining contractor Thiess was the first in the world to achieve a new level of drilling automation

Learn More -

Voisine's Christmas Tree Farm in Maine

At the Allagash View Christmas Tree Farm in Maine, three generations of Voisines are trimming, topping and tagging Fraser and Balsam Fir trees for the holidays.

Read more -

First-Ever All-Female Crew Completes 500-Hour Planned Maintenance on Cat® Truck in Peru

Learn more about how a team of women is breaking new ground in maintenance.

Learn More -

Top 6 Caterpillar Marine Boating Gear

Looking to deck out your marine vessel with exciting accessories? Check out our list of fun gear to secure before your next day at sea.

Learn More -

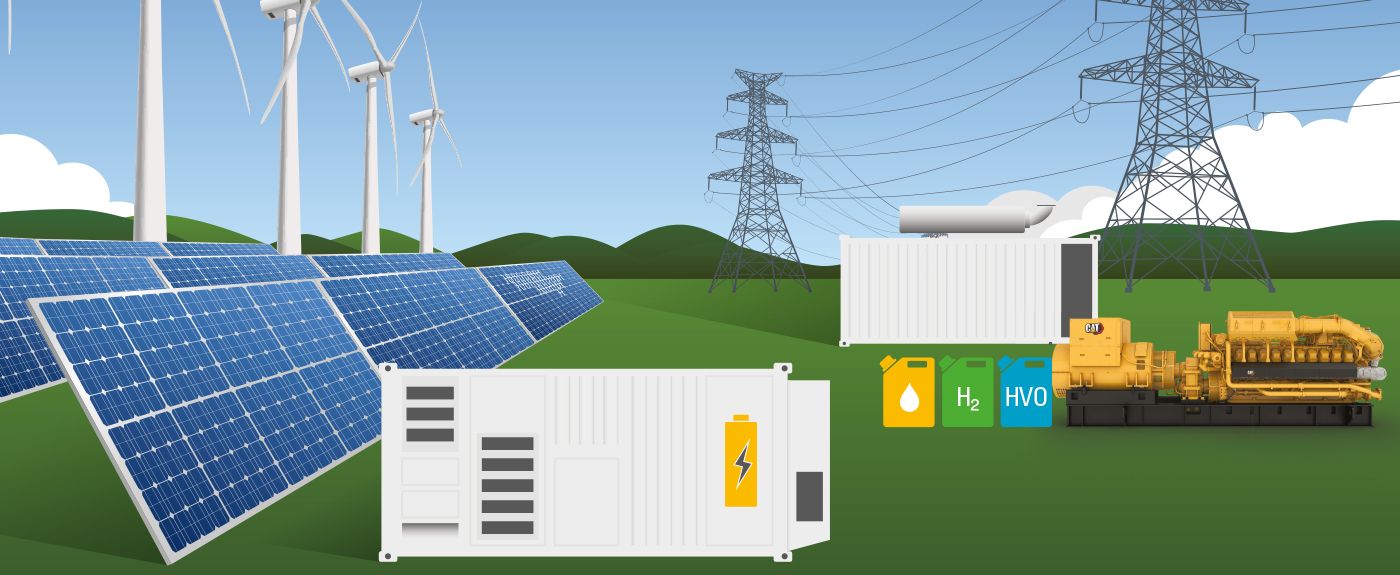

Blogs: Power Solutions for a Changing World

Power Solutions for a Changing World, Perspectives on the Energy Transition from Caterpillar

Learn More -

Trends in the Energy Transition

When it comes to the ongoing efforts to decarbonize and reduce greenhouse gas (GHG) emissions, renewables are making up more and more of our sources of power generation, and we think this will continue—for many positive reasons. We have a lot of customers who are setting targets for Environmental, Social, and Governance (ESG) goals, aiming for improved carbon reduction.

Learn More -

6 Songs With Nautical Vibes For Sailing The Tides

While nothing floats a boat quite like a Cat® Marine engine, we believe nothing can rock a boat better than these 6 songs. Whether you’re in the mood for a cheerful country hit to accompany a day of smooth waters and sunshine or some Yacht Rock to get your feet dancing on the deck, this list has something for every sailor.

Learn More -

Customer Value Agreements: The Secret To Hassle-Free Ownership

Cat® Customer Value Agreement (CVA) contracts offer complete support and peace of mind when owning a Cat machine. Pon Norway’s customer, Rental Group, explains why CVAs are vital to their business.

Read more -

Cat® Rope Shovels in Peru Achieve Highest Availability in the World

See how Cat electric rope shovels at Southern Peru Copper Corporation's Cuajone mine achieved record-setting availability.

Learn More -

Digging Up the Past

Discover why Ardis Archeology, one of the world’s leading archaeologists, uses Cat machines on their digs.

Read more -

Ryan’s Recycling

We can all reduce landfill waste—just ask 10-year-old Ryan, who’s making a global impact with recycling containers. See how his story inspired the Cat® team at WasteExpo.

Read his story -

New Cat® AD30 goes to work in shaft mine after complicated mine transfer process

Get a closer look at how one U.S. mine got a new piece of large equipment underground quickly and safely — so it could get to work.

Learn More -

A Layered Approach to Fatigue and Distraction Management

See how two mines owned by PanAust Limited have approached fatigue and distraction management.

Learn More -

How to Stay Warm When Working in the Cold

Whether you’re on the jobsite or tackling your own projects, it’s important to know how to stay warm working outside in the winter. See our tips for working in the cold.

Learn More Safety -

Setting the Standard: The History of the Iconic Cat® 992 Large Wheel Loader

Since 1968, the 992 has been setting the bar for large wheel loader performance. Learn more about this machine's history — and what comes next.

Learn More -

Making “Dumb” Iron Smart Lands Engineer a Patent for Pump Electronic Monitoring System

Meet Derek Kamp, one of the patent-earning minds behind our Pump Electronic Monitoring System (PEMS) and countless other Cat® innovations.

Learn More -

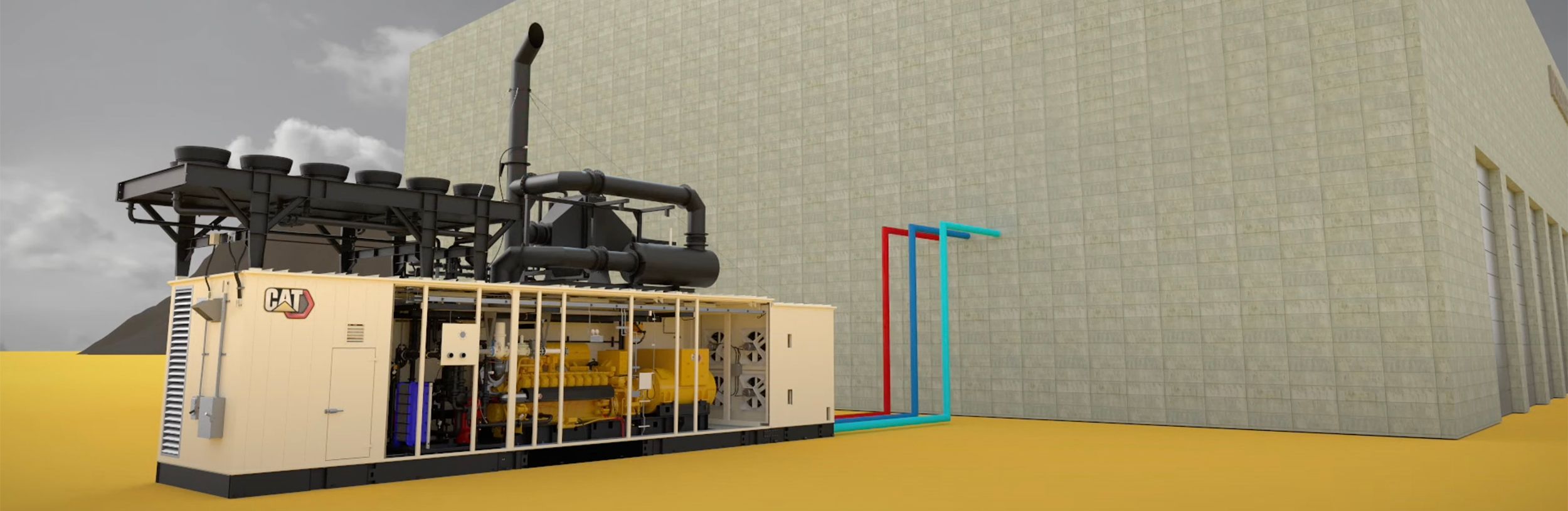

Distributed Energy Benefits and Grid Systems Integration

Our electric power system faces many challenges, and as the energy landscape evolves to address increased electrification, we will have even greater demand than ever before. Caterpillar is positioned to serve as a trusted partner with the technologies and expertise to provide alternatives to established energy sources and fuels that are reliable and cost effective.

Learn More -

NEOM – A City Like No Other

The world’s largest and most exciting new building site, NEOM, sets a new standard for what a city should look like. See how our equipment and Cat dealer, Zahid Tractor, support the project.

Learn More -

Building the Next Generation Cat® Hydraulic Mining Shovels

Learn more about the design philosophy behind our latest and greatest hydraulic mining shovels.

Learn More -

Outstanding Women of the Oil & Gas Industry: Part II

In this post, we’re highlighting women in the industry and detailing their contributions and the challenges they face.

Learn More -

Day in the Life: Derek Kamp

At Caterpillar Oil & Gas, we help our customers do the work. To do this, the leadership in the Oil & Gas division must be as strong as the yellow iron that Caterpillar is known for. Enter Derek Kamp!

Learn More -

The Growing Prominence of Sustainability in the Oil & Gas Industry

Caterpillar's technology and expertise help companies in the oil and gas industry meet their environmental social governance (ESG) goals while remaining competitive.

Learn More -

Is Engine Downsizing the Right Fit for You?

While the energy transition has introduced a wide range of new technologies for powering off-highway equipment, the tried-and-true internal combustion engine will continue to be the dominant workhorse on worksites for the foreseeable future.

Learn more -

Ensuring the Successful Implementation of New Technology in Botswana

See how technology is helping a customer in Botswana build a safer, more productive operation.

Learn More -

Scale Studies Help Mining Companies Maximize Payload, Reduce Fuel Burn and Increase Production

Learn more about how scale studies can help to optimize loading and hauling operations.

Learn More -

Visit Vegas Like a Local for CONEXPO

Find tips for enjoying CONEXPO and beyond, from Fremont Street to the Las Vegas Strip.

Learn More -

Cat Machines That Are Rebuilt to Last

With Cat Certified Rebuild Solutions gaining popularity, we discover how one company in the UK seized the opportunity.

Learn More -

Teknoxgroup and Customers Work Together With One Aim In Mind

Big, small or in-between, Teknoxgroup helps your business run smoothly.

Learn More -

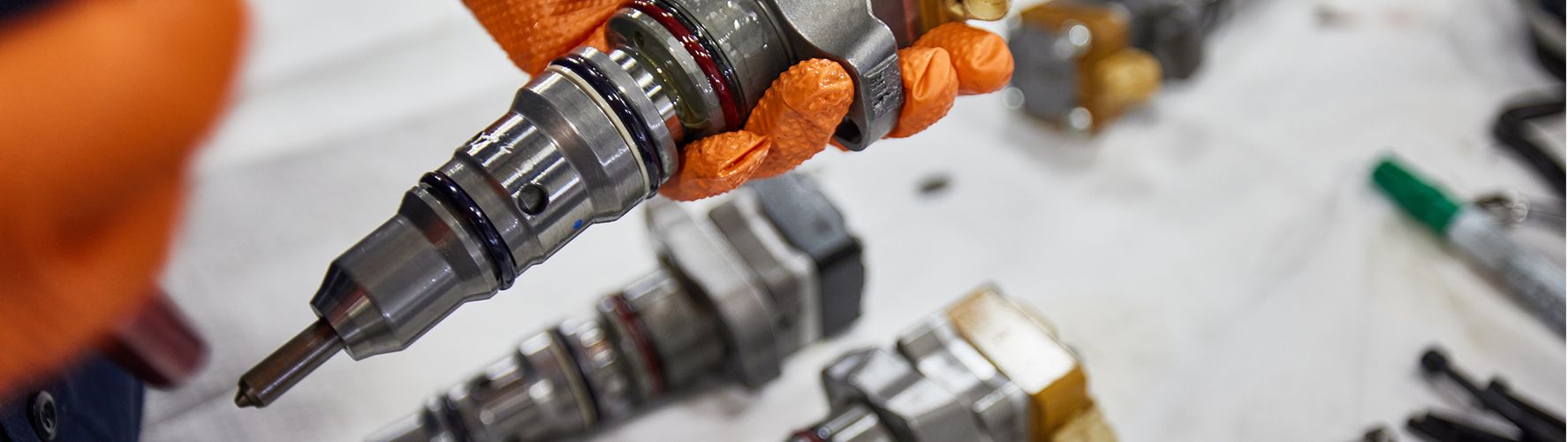

An Inside Look at Cat® Reman Fuel Injectors

Follow an injector through the Cat® Reman quality validation and testing process.

FOLLOW THE PROCESS -

Equipment Protection Plans: Coverage & Finance Options

Discover the benefits of having an equipment protection plan. Learn how safeguarding your Cat machinery with a comprehensive plan can mitigate risks and enhance long-term performance.

EXPLORE PROTECTION -

Caterpillar: Making a Big Impact at CES 2023

We had a big presence at CES 2023 — check out our booth and learn more about why we were there.

Learn More -

Day in the Life: Ross Stoneham

At Caterpillar, we help our customers do the work and to do so we hire talented individuals that understand customer needs and create solutions to help them. Meet Ross Stoneham an Engineering Manager for Caterpillar Marine who leads a team of engineers working everyday to create equipment that supports operators within the marine industry.

Learn More -

Cat® Reman 50: The People Who Make It Possible

Hear from some of the people who’ve made Cat® Reman possible for 50 years and counting.

HEAR THEIR STORIES -

Cat® Customers Team Up To Build Major League Soccer Stadium

St. Louis is celebrating their new MLS Stadium, CityPark, which Cat dealer Fabick supported in the MAK joint venture building the stadium and supporting complex.

Learn More -

Cat® Electric Rope Shovels: Leading the Way in Efficiency and Reliability ― and Continuing to Improve

Cat Electric Rope Shovels are built on a legacy of success going back more than 140 years. Learn more about our history — and see where we're going next.

Learn More -

Gifts for DIY Moms

What are the best gifts for the women in your life — those who don’t mind a little dirt and a lot of hard work? We’ve pulled together a great selection of options for women of all ages and interests in our Gifts for DIY Moms guide.

Shop Now Merchandise -

Gifts for Construction Loving Kids

Cat® excavator toys and Cat bulldozer toys and Cat remote control dump trucks, oh my! If the kids on your shopping list can’t get enough Cat construction toys, our Gifts for Construction Loving Kids guide has you covered with long-lasting presents that will have them jumping for joy.

Shop Now Merchandise -

Gifts for Construction Workers

Your friends and family who work in the trades know the value of quality and durability — and that’s exactly what these gifts for construction workers, contractors and builders deliver. Give the perfect gift from our Gifts for Construction Workers guide.

Shop Now Merchandise -

Gifts for Gearheads

Struggling with what to get a gearhead? If you’re shopping for someone who loves cars, trucks, tools and tinkering with stuff in the shop or garage, then our Gifts for Gearheads guide is a great place to start your search.

Shop Now Merchandise -

Gifts for Outdoor Lovers

Hunters, anglers, hikers, campers, boaters, skiers — we’ve pulled together a great selection of gifts for outdoorsy people on your shopping list. And everything in our Gifts for Outdoor Lovers guide is built tough and made to last in any kind of weather or conditions.

Shop Now Merchandise -

Career Advice from Cat Customers

Looking for some career related advice? We recently asked our social media followers for the best career advice they’ve received from a co-worker. Read their top tips.

Read More -

Cat Reman Aims to Reduce Waste at Each Step

The Cat Reman team is always looking for new ways to reduce remanufacturing waste.

SEE THE STEPS -

Caterpillar Showcases Technology and Autonomy Leadership at SME’s MINEXCHANGE 2023

We joined other industry leaders and innovators to discuss the future of the mining industry.

Learn More -

Turning the Desert Green

A massive project in the Nuban Desert brings jobs, food and a brighter future to Sudan. See how Cat Dealer Sutrac provided support with rental machines.

Learn More -

Cat® Reman Process: Recycling While Remanufacturing

How Cat Reman incorporates recycling and sustainability benefits.

SEE THE BENEFITS -

Gifts for Construction Dads

We’ve rounded up the most useful gifts for men — heavy-duty gear he’s sure to enjoy on the job, around the house, in the garage or on his days off. It’s all here in our Gifts for Construction Dads guide.

Shop Now Merchandise -

Quality Control for Cat® Reman Cylinder Packs

Cat Reman focuses on quality in each step of the cylinder pack assembly remanufacturing process.

CHECK OUT THE PROCESS -

How Cat® Reman Works with Repair and Rebuild Options

Cat Reman parts’ off-the-shelf model helps lower equipment repair and rebuild cost.

EXPLORE BENEFITS -

1,000th Cat® 24 Motor Grader Arrives in Australia

Caterpillar leadership and production team members celebrated the production and sale of the 1,000th 24 motor grader last fall, and now it's hard at work on a customer site in Australia.

Learn More -

Meet True Grit Transportation

Meet True Grit Transportation, the Texas-based, bulk-commodity haulers who trust Cat® truck engines to help get the job done.

Learn More -

Hydrogen’s True Colors: A Key to Defining Carbon Intensity

Often referred to as a “clean-burning” fuel, hydrogen is the most abundant chemical substance in the universe because its combustion generates near-zero greenhouse gas emissions at the tailpipe. . It’s also colorless, odorless and burns with a near-invisible flame. So why does nearly every Google search or news story about hydrogen turn up terms like “green,” “blue” and even “pink”?

Learn More -

Field Follow Program Gives Customers What They Want

Discover how the Field Follow Program makes our machines better and our customers more loyal.

Read more -

Cat® Reman Engine Remanufacturing: First Steps

The Cat® Reman engine remanufacturing team outlines the precision process step by step.

VIEW STEP ONE -

Cat® Reman Engine Remanufacturing: Reclaim and Salvage

Quality engine remanufacturing is achieved through precise parts cleaning and inspection.

See Reman Reclaim and Salvage -

Cat® Reman Engine Remanufacturing: Assembly, Testing

In the final phase of engine remanufacturing, Cat Reman assembles and tests components.

See Reman Assembly and Testing -

What Happens to an Engine at Cat® Reman Facilities?

Your equipment’s engine has gotten you through job after job for many years. Now what?

LOOK INSIDE CAT REMAN -

Behind the Scenes: Life as a Cat® Diesel Tech featuring Adept Ape

Get an insider's look into the daily life of Adept Ape, a Cat diesel tech and YouTube creator, and his advice on how to kickstart your own career at Caterpillar.

Read more -

Day in the Life: Lizzie Hurt

The oil and gas industry is complex, and our customers routinely have special needs and custom requests. Lizzie Hurt, sales support engineer, is on call to do whatever is needed to make sure her customers are taken care of. When she’s not at work, Lizzie and her husband love spending family time with their two dogs and pursuing all sorts of outdoor activities.

Learn More -

Day in the Life: Charlotte Guest

Innovation is at the forefront for our engineering teams, as they work to determine the next products and solutions to help our customers with their operations. Meet Charlotte Guest, one of our marine engineers who leads a team to test, design and program our next great products.

Learn More -

Cat® Oil and Gas Blog

The oil and gas industry is constantly changing, offering operators new solutions, trends, and products to adopt so they can do what they do best. Read the blog posts below and go beyond the iron of Cat® Oil and Gas products to help you stay ahead of the game.

Learn More -

Using Cat® Reman Parts for Equipment Rebuilds

Consider when to use Cat® Reman parts in a component, engine or complete machine rebuild.

Learn More -

Introduction to The Energy Pipeline

The oil and gas industry is witnessing a remarkable evolution. The way the industry operates has fundamentally changed since the peak of 2014. There are multiple factors in play that are driving these changes, from capital availability to fluctuating oil prices to sustainability goals and more.

Learn More -

Meet Your Co-Host: Lizzie Hurt

The oil and gas sector is one of the most technically complex industries imaginable. The expertise and innovations required to produce energy that powers homes, cars, electronics, hospitals – entire economies – are the result of expert engineering. Onshore or offshore, every job is different. As a Caterpillar Oil & Gas Sales Support Engineer, Lizzie Hurt understands this well.

Learn More -

Meet Your Co-Host: Wayne Zemke

Constant change is a characteristic of the oil and gas industry. Markets change, regulations change, technologies change—and with each change, companies need to understand how to adapt to continue to grow their businesses. With co-host Wayne Zemke, Market Intelligence Manager for Caterpillar Oil & Gas, the Energy Pipeline podcast is a source for information and expert perspectives on the evolving energy industry.

Learn More -

Meet Your Co-Host: Adriana Herrera

Price volatility and inflation concerns have made more oil and gas companies aware of the need to reduce costs by streamlining every process possible and eliminating unnecessary steps. This can be a challenge when last-minute service requests are common, as operators and oilfield service providers grapple with readying units for operation to meet job deadlines.

Learn More -

It's Time for "Haul Talk"

Join hosts Kurt and Zach for Haul Talk, the Cat® truck engine podcast with trucking tales and tips to help keep you rolling.

Learn More -

Meet Your Co-Host: Bill Jensen

As a 40-year industry veteran, SPM Oil & Gas Senior Technical Fellow and Technical Services Manager Bill Jensen has seen it all – and he looks forward to bringing the benefit of his hard-earned insight to The Energy Pipeline podcast as a co-host to share how the industry is responding to today’s challenges.

Learn More -

Gear Up for the 2023 New School Year

Shop our Cat branded back-to-school must-haves, including a Caterpillar backpack, hats, a water bottle and more. Check out our list of Cat merch for students of any age.

Learn More -

HVO Engines

Read about the Cat® C Series engines that can operate on Hydrotreated Vegetable Oil (HVO) fuel while reducing CO.

Read more -

Cat® Onboard Technology

Next Generation Cat® excavators set a new standard for technology in the cab. Learn how Cat Onboard Technology makes it easier, faster and cheaper to do your job.

Read more -

Caterpillar Employees Participate in Women in Mining USA Annual Conference

Nearly 20 women from Caterpillar mining attended the conference to learn more about the growing role of women in the industry — and to demonstrate Caterpillar's role as a leader in diversity and inclusion

Learn More -

More Than 80 Patents Protect Cat Reman Innovation

Learn about some of the proprietary tech that makes sure Cat Reman quality is spot on.

SEE HOW -

Caterpillar and AI: Three Ways Smart Technology Makes Work Easier

Learn how Caterpillar utilizes AI within our technology product offerings, including applications in fleet management, equipment maintenance and parts.

Learn More Technology -

Delivering Unparalleled Results in New South Wales

Learn more about why most of the surface mines in New South Wales, Australia, choose to use Cat drills

Learn More -

Thieves 0 – Caterpillar 1

The fascinating (and true) story of how Visionlink® helped recover a stolen Cat® Backhoe Loader.

Learn More Technology -

History of Cat® Trucking

We've come a long way since the first Cat® on-highway truck engines hit the road. Learn more about our trucking history.

Learn More -

Demystifying the EaaS Model: Don’t Buy Power Products. Buy Energy Outcomes.

Software as a Service, or SaaS. Today, most applications — everything from Microsoft Office to Google Drive to Salesforce — are hosted by a third-party provider and made available via the web or a mobile app. You don’t need to install or configure anything on your computer, and the SaaS provider handles all maintenance, upgrades, and licensing. It’s more convenient for users and more affordable for businesses.

Learn More -

I Know What You Did Last Summer - Part 1

School’s out and internship season has officially begun! Students from across the country joined Caterpillar’s internship program to develop their skills as they worked alongside our oil and gas and marine experts. Our Confessions of an Intern series highlights their unique perspectives, infectious personalities, and memorable experiences as a Caterpillar Oil & Gas and Marine Intern.

Learn More -

Caterpillar and the Diversified Naval Fleet: Manned, Unmanned and Autonomous Vessels

The maritime branch of a nation’s armed forces spans across a wide range of activities. Naval vessels have developed over time from wooden sailing ships stocked with cannons to today’s technology-laden ships and submersibles.

Learn More -

Rebuilding (or Refurbishing) vs. Repairing Heavy Equipment

What’s a better choice: heavy equipment rebuilding (often referred to as heavy equipment refurbishing) or repairing? Compare the differences.

SEE FOR YOURSELF -

What To Know About Repaired Heavy Equipment

Buying repaired heavy equipment can save you money. But will it perform to your expectations? Follow these four steps to feel more confident in your purchase.

FOLLOW THESE STEPS -

How Cat Approaches Heavy Equipment Repair

Here’s what to expect from your Cat® dealer when repairing heavy equipment, doing Self-Service Options for do-it-yourself repairs.

BE IN THE KNOW -

Repairing Heavy Equipment: Four Factors To Consider

See how your Cat® dealer factors in ownership, utilization, affordability and turnaround time to help you choose the best option for repairing heavy equipment.

DIVE IN -

How We Reclaim and Salvage Equipment Parts

Cat® Reman’s cleaning and salvage processes are essential to remanufacturing parts.

SEE HOW IT WORKS -

A History of Three Shale Formations: Part One – The Permian Basin

The Permian formation is a unique and noteworthy part of a larger historical mosaic.

Learn More -

A History of Three Shale Formations: Part Two – The Marcellus Shale

The Marcellus Shale plays a pivotal role at home and abroad.

Learn More -

Top Tips to Finding the Right Parts for Your Cat Machine

Learn easy ways to quickly find parts that fit and how to ensure you get the right part for your Cat equipment, every time online.

Learn More Technology -

Behind the Screen: A Sit down With a Developer of Cat Central

Our CX project manager, Ben Geyer, sits down with us to share what really goes into developing an app.

Learn More -

Ready to Serve: Caterpillar Defense Powers Government and Military Operations

Beginning with World War I, the Armed Forces of the United States have relied on Cat® equipment. That relationship continues today, as Caterpillar supports men and women in uniform as well as federal civilians with leading-edge solutions and global support.

Learn More -

Driving Operational Efficiency: Fresh Insights to Increase Safety and Reduce Downtime

Worksite safety and operational efficiency are foundational elements of success in the oil and gas industry. Habitual maintenance practices underpin both in today’s oil patch. While training is essential, digital tools complement workers’ efforts to inform them about unseen issues that can force equipment offline.

Learn More -

Engine Advice: When Do I Need to Adjust the Valves on My New Engine?

Engine Intake and Exhaust valves should be adjusted at the first oil change on a new engine. For Cat® Marine Engines, the first oil change could be recommended at 250, 500 or 1,000 hours, depending upon configuration. Consult your manual for specific configurations and intervals.

Learn More -

Demystifying Oil and Gas

Curious to know the difference between oil and gas, or the sustainability efforts that are taking place in the industry? The following breakdown separates oil and gas facts and fiction.

Learn More -

Expert Maintenance Enhances Total Cost of Ownership

As oilfield service providers and operators push their hydraulic fracturing equipment harder and longer, uptime is critical. Any unplanned downtime compromises efficiencies – and cuts into profitability. Oil and gas businesses can significantly reduce ownership and operating costs when utilizing experts to properly maintain and monitor equipment.

Learn More -

Learning Energy’s History and Future at Wiess Energy Hall

The Wiess Energy Hall at the Houston Museum of Natural Science offers an immersive, chronological journey through the history of energy, spanning from the Big Bang to future technologies. Originally focused on oil and gas, the exhibit expanded several years ago to encompass diverse types of energy. By providing a comprehensive understanding of energy processes—from upstream to downstream—the exhibit plays a pivotal role in educating anyone interested in the energy industry.

Learn More -

Is Your Organization a Good Fit for EaaS? And Is Your EaaS Partner a Good Fit for You?

Our EaaS team at Caterpillar has implemented solutions for all types of operations: from K-12 schools and grocery stores to industrial facilities. The concept — you purchase energy outcomes and turn ownership and upkeep of energy assets over to a third party — works for many organizations. How do you know if yours is one of them?

Learn More -

Thanks A Million

Get details on the Million Miler Club, our exclusive truck driver loyalty program with perks to reward your hard work.

Learn More -

Winter Diesel Engine Checklist

To help get the most from your machine during the cold months, prepare for winter temperatures and follow this diesel engine checklist for optimal winter performance.

Read more -

Machine Rebuild is Ideal Time for Emission Upgrades

Rebuilding machines is the ideal time to incorporate updated emission controls and take new steps toward improving air quality inside underground mines.

Learn More -

Proactively Improving Rope Shovel Uptime at New Peru Copper Mine

See how we worked with Anglo American to reduce boom jack events at their new copper mine.

Learn More -

What’s Caterpillar Doing at CES 2024?

Showcasing Real Solutions Addressing Real Problems in Real Applications

Learn More -

I Know What You Did Last Summer - Part 2

Summer may feel far away, but it’s always internship season at Caterpillar. Each year, talented young professionals spend several months learning from the industry’s experts. Like most internships, each intern’s skill set is diverse — and so are their personalities! "Confessions of an Intern" showcases each intern's unique perspective, infectious personality and individual experience at Caterpillar Oil & Gas and Marine.

Learn More -

Cat® G3600 Engine Continues to Evolve to Meet Operators’ Needs

Learn about the improvements the Next Gen Cat® G3600 Engine brings to the oil and gas industry.

Learn More -

Energy Innovators Wanted

Energy Innovators Wanted

Learn More -

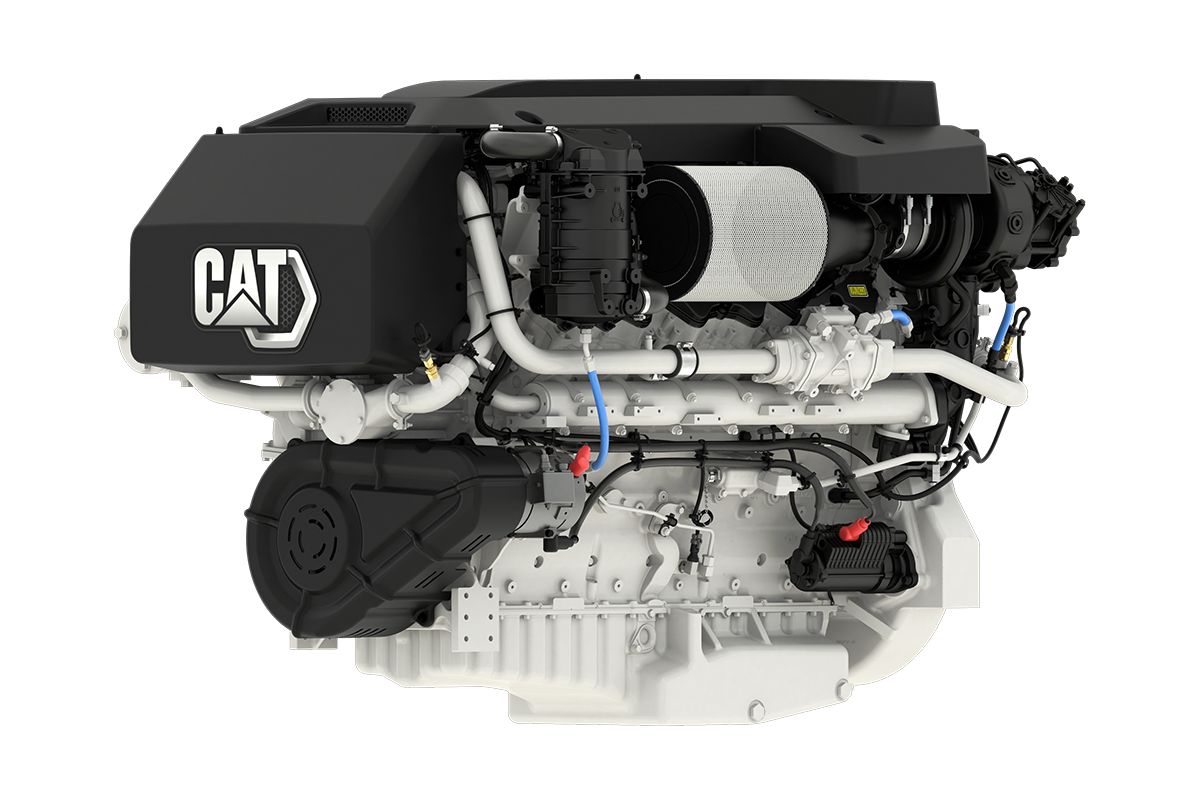

C32B Simplicity and Design

A Renowned Yacht Designer Shares Today’s Yacht Building Trends.

Learn More -

Using Technology to Boost Efficiency and Lower Costs

See how Cat® MineStar™ is helping one customer site become more efficient.

Learn More -

Addressing the Risk of Operator Fatigue and Distraction

Learn more about how the Cat® Driver Safety System helped on customer site address the risks of fatigue and distraction on their site.

Learn More -

8 Tips to Prolong Engine Life and Reduce Operating Costs through Preventative Maintenance

Let's explore simple ways to keep your engine in top shape.

Read more -

Day in the Life – Matt Rayson

Aftermarket sales are a large focus for Caterpillar. Matt Rayson has been a marketing strategist in various roles and global locations, supporting the service and support needs for customers and dealers.

Learn More -

Caterpillar Technology Enables Out of This World Solutions

Learn how Caterpillar’s efforts in autonomous technology, robotics and soil simulation are helping NASA with excavation & construction projects on the moon.

Learn More Technology -

Fraccing has resulted in energy security, but questions remain

Hydraulic fracturing (“fraccing”) is a complex, multi-step process that allows access to previously inaccessible oil and natural gas reserves.

Learn More -

A Career Spent Alongside the G3600

When the G3600 debuted in 1991, Bobby Runnels was just starting out as a technician. See where more than three decades have taken him and this gas compression engine.

Learn More -

Day in the Life: Hassan Khalid

As a senior strategy consultant, Hassan Khalid guides Caterpillar's gas compression product strategy to continue to meet industry and market demands.

Learn More -

What To Know About Buying Rebuilt (or Refurbished) Heavy Equipment

What’s included in heavy equipment rebuilding (often referred to as heavy equipment refurbishing)? And what can you expect from a rebuilt machine? Get answers.

GET DETAILS -

Benefits of Rebuilding (or Refurbishing) Heavy Construction Equipment

Heavy equipment rebuilding (often referred to as heavy equipment refurbishing) is a smart way to get more value out of your investment. Explore the benefits.

DISCOVER MORE -

Stepping Out of the Machine's Shadow

Learn more about how we're helping companies as they eliminate live work in order to improve technician safety.

Learn More -

5 Steps to Sign-Off on a New Energy Solution

You’re a large energy consumer, maybe in healthcare, education, distribution or transportation. You’re facing pressure — internal, external or both — to increase your energy resiliency, lower your carbon emissions, reduce your energy costs, add capacity for expansion, or some combination of all four. You know you need to act (and soon), but you’re struggling with how to get started implementing a solution.

Learn More -

Act Now to Leverage CHP Tax Credits Up to 50%

The Inflation Reduction Act (IRA), signed into law in August 2022, provides nearly $400 billion in tax credits and incentives over a decade to promote climate change mitigation and stimulate clean energy development in the U.S. It’s the largest single investment in climate and energy in American history — and it includes the highest incentives ever provided by the federal government for combined heat and power (CHP) projects.

Learn More -

Marching On 2024: Taking Strides Towards Wellbeing

In the bustling world of Caterpillar, gears are always turning, and engines are relentlessly powering progress. Amidst the steel, sweat, and innovations, there's a unique tradition that has steadily become a beacon of well-being – the Marching On event.

Read more -

Contractor Helps Employees Live Safe and Work Safe with Support from Caterpillar Safety Services

See how one customer partnered with Caterpillar Safety Services to help create a people-first safety culture across all their operations.

Learn More -

FAQS: What Are Renewable Fuels?

Renewable diesel fuels… they're kind of like nature's gift to our engines. So, what is renewable diesel fuel, exactly? We're talking about fuel made from stuff like soy, palm, canola, even used cooking oil and animal fat.

Read more -

Caterpillar Equipment Model Name & Number Basics

Learn the meaning behind Caterpillar equipment model names, including their history, what the model numbers & letters mean and how new products are named.

Learn More -

Remote Services

Remote Services is a technology suite that improves jobsite efficiency by enabling diagnostic testing and remote updates to connected machines.

Learn More -

The Circular Dance

If you were to ask a man on the street what he associates with the oil and gas industry, images of oil derricks, massive tankers, and petrol pumps are likely points of reference. While it’s viewed by some as a smokestack industry steeped in the past—don’t be mistaken—the oil and gas sector is taking bold strides into the future, dancing to the rhythm of the circular economy.

Learn More -

Cat® Industrial Power Blog

Welcome to the Cat Industrial Power Blog, your go-to source for the latest insights and updates in the industrial power space. Dive into informative articles, technical insights, and maintenance tips from Caterpillar's power systems experts.

Read more -

Hybrid Technologies Deliver Efficiencies That Add Up

As fuel is always one of the greatest expenses in the oilfield, technological advances that drive greater efficiencies are top of mind for E&P s and drilling operators. Newly available electrification and optimization technologies lower fuel consumption and related greenhouse gas emissions while maintaining on-site reliability and durability.

Learn More -

A Performance Evaluation Tool for Today’s Gas Compression Operations

Choosing the right engine for a gas compression site is an important step. However, reliably predicting engine performance and tracking key metrics is essential for operational success in today’s energy landscape. As sustainability becomes increasingly important, operators require a tool that provides site-specific performance estimates to select the most appropriate engine solutions.

Learn More -

Addressing Tomorrow's Workforce Challenges

The U.S. oil and gas industry supports 10.8 million full-time and part-time jobs in all 50 states, making up 5.4 percent of the country’s workforce, and contributes nearly $1.8 trillion per year to the U.S. economy, according to an American Petroleum Institute report prepared by PricewaterhouseCoopers in 2021.

Learn More -

Cleaner. Faster. More Powerful.

Learn more about how the R2900 XE Diesel-Electric Underground Loader helps sites reduce exhaust emissions.

Learn More -

The Right Tools For the Job

Learn more about the Ground Engaging Tool options available for the R2900 XE Diesel-Electric Underground Loader.

Learn More -

Leveraging Hybrid Technologies to Reduce Fuel Costs and Increase Efficiency

Operators and drilling companies continue to focus on reducing fuel costs and increasing operating efficiency while reducing greenhouse gas (GHG) emissions. The Cat® Hybrid Energy Storage Solution helps address these needs as it enables companies to reduce diesel use and related emissions.

Learn More -

Understanding the Differences Between Lean-Burn and Rich-Burn Engines

Essential Considerations to Determine Which Type of Engine is Most Beneficial for Your Gas Compression Project

Learn More -

How Municipal Utilities Can Address Surging Power Demand

For many municipal utility managers I talk to, it’s getting tougher to continue providing the highest levels of reliability, service, and value. Customer preferences are changing. Some want 100% renewable power overnight; others simply care about cost. Other challenges are mounting, too: New technologies. Increased regulation. Workforce shortages. Budget constraints. And perhaps biggest of all, rising demand.

Learn More -

The Evolution of a Workhorse

Gordon Wilkin, Caterpillar, Inc., reviews the evolution of the CAT® R2900: an LHD on the verge of celebrating 30 years since its first introduction to the mining industry.

Learn More -

Welds Worthy of the Work

Discover how Caterpillar welders use the latest technology to deliver consistent, high-quality welds that meet our manufacturing standards and exceed your expectations.

Learn More -

Day in the Life: Michael Weidenfeller

Product strategy manager for drilling and mobile power applications Michael Weidenfeller works with both engineers and oil field companies to provide the right solution for their global drilling needs. He combines his love of business with his ability to interpret engineering terminology to enable customers to understand all the power management solutions available to them.

Learn More -

Financial Tips to Lower Construction Employee Turnover

Take steps to reduce construction employee turnover with these Cat Financial solutions.

FIND OUT MORE -

The Cat® 995 Wheel Loader: A High-Efficiency Leader

The Cat® 995 Wheel Loader moves more material than its predecessor, the 994K, for significantly less cost. Not only does it deliver a larger payload — it’s also infused with efficiency enhancements that help sites get more done in less time, with less fuel.

Learn More -

A Lasting Legacy

Flor Rivas, Caterpillar Inc., USA, celebrates 130 years of Caterpillar operations out of South Milwaukee in a Q&A with Will Owen, Editor of Global Mining Review

Learn More -

A History of Three Shale Formations: Part Three – The Haynesville Basin

The Haynesville Basin represents a journey through time, resilience and energy triumph.

Learn More